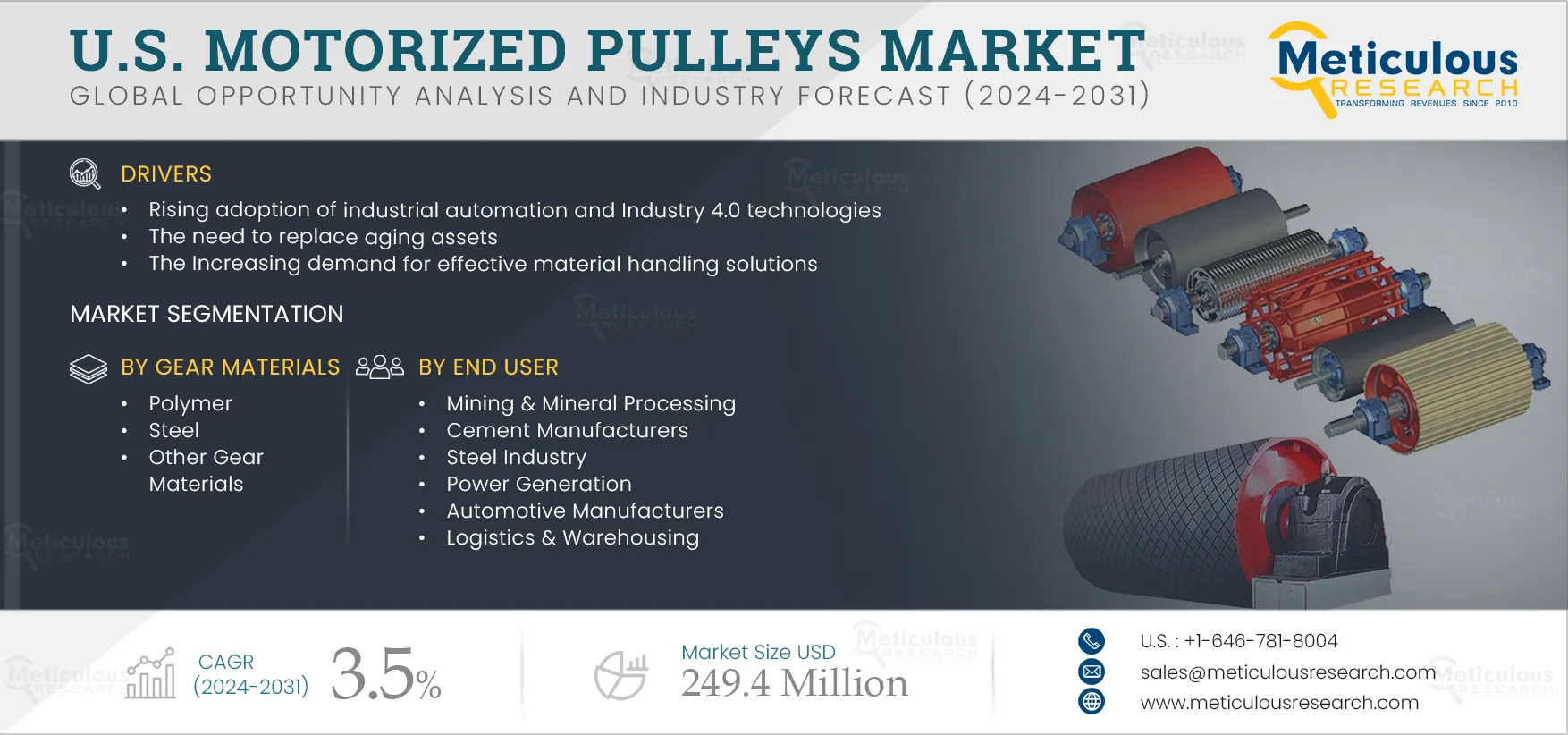

The U.S. Motorized Pulleys Market is expected to reach $249.4 million by 2031, at a CAGR of 3.5% from 2024 to 2031. The growth of the U.S. motorized pulleys market is driven by the increasing adoption of industrial automation and other Industry 4.0 technologies, the rising need to replace aging assets, and the growing demand for material handling solutions. However, suboptimal overall efficiency due to motorized pulleys’ compact designs restrains the growth of this market.

Additionally, the growth of the e-commerce and logistics sectors and advancements in motor and control technologies are generating growth opportunities for the stakeholders in this market. Furthermore, the higher investment requirements of motorized pulleys compared to traditional pulleys are a major challenge restricting market growth.

Here are the top 10 companies operating in the U.S. Motorized Pulleys Market

Founded in 1962 and headquartered in Bergamo, Italy, Rulmeca Holding S.p.A. is a leading manufacturer of conveyor rollers/idlers, motorized pulleys, fabricated pulleys, and other components for bulk handling and unit handling processes. Rulmeca provides a wide range of unit-handling products, including gravity conveyor rollers, chain-driven roller conveyors, curve roller conveyors, belt-driven roller conveyors, unit-handling pulleys, drive rollers, drum motors, and pallet rollers. The company’s unit-handling products are used for various applications, including airport security and X-ray screening, postal, parcel & e-commerce, manufacturing, packaging and automation, distribution centers & warehousing, food & fish processing, and beverage processing.

Rulmeca’s bulk handling solutions are widely utilized in mining & minerals extraction, cement production, steel & power plants, recycling facilities, ports, and import-export terminals. The company offers a range of motorized pulleys in various models and sizes tailored for light, medium, and heavy-duty conveyors. These motorized pulleys feature geared motor drives that are hermetically sealed within a cylindrical steel shell.

Moreover, the company has a strong geographical presence across the U.S., Canada, Asia, Europe, and Africa through its subsidiaries and strong distribution network. Some of its subsidiaries are Rulmeca Melco (PTY) LTD (Australia), Rulmeca Canada Limited (Canada), Rulmeca Corporation (U.S.), Rulmeca UK Ltd (U.K.), Rulmeca AB (Sweden), RULMECA GERMANY GmbH (Germany), and Rulmeca France Sas (France).

Van der Graaf Inc.

Established in 1985 and headquartered in Ontario, Canada, Van der Graaf Inc. is engaged in the design and manufacturing of belt conveyor components. The organization provides reliable material handling solutions to several industries. Van der Graaf offers a wide range of products, including drum motors, crossdrive, and belt cleaners.

The organization’s motorized pulleys are widely used across food processing, mining, airline baggage handling, warehousing, and postal & parcel services. They provide motorized pulleys with a wide range of diameters, horsepower ratings, belt speeds, and industry-specific options and features designed to meet a wide range of belt conveyor applications. Moreover, the organization has a strong geographical presence across the U.S., Canada, and the Netherlands through its strong distribution network.

Founded in 1959 and headquartered in Sant ‘Antonino, Switzerland, Interroll Group is a leading provider of material-handling solutions. Interroll provides a wide range of products such as rollers (conveyor rollers), drives (motors and drives for conveyor systems), conveyors & sorters, and pallet handling (flow storage systems). The company also offers pallet handling products such as modular pallet platforms, stacker cranes, transfer cars, pallet flow, and smart pallet movers.

Interroll provides tailor-made and standard product offerings to original equipment manufacturers (OEMs), system integrators, and other end users. The company’s motorized pulleys are used in various industries such as postal, e-commerce, airports, food & beverage, fashion, and automotive. Moreover, the company has a strong geographical presence across the Americas, Asia-Pacific, Europe, and the Middle East & Africa.

Sparks Belting

Established in 1946 and headquartered in Michigan, U.S., Sparks Belting is a manufacturer of conveyor belting and motorized pulleys. The firm offers a wide range of products, including lightweight conveyor belts, modular plastic belts, timing belts, heavy-duty conveyor belts, and motorized pulleys. Sparks Belting’s offerings are used across various industries such as automotive & tire, building materials, food, logistics & warehouse distribution, and paper & print.

Sparks Belting’s offerings consist of the Dura Drive plus motorized pulleys and the Dura Drive SPM motorized pulleys. Its motorized pulleys come with press-fit or bolt-on end caps for easier servicing. Moreover, the firm has a strong geographical presence across the U.S. and Mexico through its strong distribution network.

Founded in 1986 and headquartered in Michigan, U.S., Mol Belting Systems, Inc. specializes in conveyor belts, motorized pulleys, and conveyance accessories. The company offers a wide range of products, including conveyor belts, PTFE (polytetrafluoroethylene) belts, fabric & tapes, motorized pulleys & driven rollers, belting adhesives & accessories, and other conveyor components.

The company’s motorized pulleys offer numerous benefits, including high efficiency, low noise, space savings, durability, and longevity across various industries. Additionally, it provides a non-oil-filled motorized pulley suitable for many light product applications, along with advanced driver card controls that facilitate easy implementation. Mol Belting’s products find applications in food processing, logistics, parcel handling, warehouses, treadmills, and checkouts.

Shipp Belting Company

Founded in 1938 and headquartered in Texas, U.S., Shipp Belting Company manufactures conveyor equipment and belting products. The company offers a wide range of products, including lightweight conveyor belts, heavy-duty conveyor belts, positive drive belts, wire belts, modular plastic belts, power turn belts, profile belts, and timing belts. Shipp Belting also offers motorized pulley, PTFE (polytetrafluoroethylene) fabric, tapes, conveyor components, needled products, custom fabricated and molded parts, and belt fasteners.

Moreover, the company’s offerings find application across various industries, including food & beverage, waste & recycling, corrugated/paper and print, building materials, mining, e-commerce, distribution & logistics, wood & lumber, and agriculture.

Founded in 1999 and headquartered in Helsinki, Finland, Metso Corporation provides solutions & services for the aggregates, minerals processing, and metals refining industries. The company offers various mobile equipment and stationary equipment such as crushers, screens, conveyors, chutes, and feeders. Metso also offers various services such as life cycle services, maintenance and repairs, modernizations and upgrades, and process optimization.

The company offers a wide range of conveyor pulleys, including head pulleys, tail & wing pulleys, snub pulleys, drive pulleys, bend pulleys, and take-up pulleys. The company operates in the market through two reportable segments: Aggregates and Minerals.

Furthermore, the company has a strong geographical presence across Europe, Asia-Pacific, the Americas, and the Middle East & Africa through its subsidiaries and a strong distribution network. Some of its subsidiaries are Metso Heavy Industries (Quzhou) Co., Ltd. (China), Metso Algerie EURL (Algeria), Metso Finland Oy (Finland), Outotec Holding GmbH (Germany), Metso Outotec India Private Ltd (India), and Metso Italy Srl (Italy).

Tech-Roll, Inc.

Headquartered in Washington, U.S., Tech-Roll, Inc. is a manufacturer of high-precision, heavy-duty power transmission equipment for the conveyor industry. The organization offers various products, including hydraulic motors and hydraulic profiled drum motors. Tech-Roll also offers repair services for its customers.

The organization’s offerings are used across various industries, including meat & poultry, wood & lumber, seafood, agriculture, sand & gravel, and food processing.

HIMMEL Antriebstechnik GmbH & Co. KG

Founded in 1947 and headquartered in Gescher, Germany, HIMMEL Antriebstechnik GmbH & Co. KG (HIMMEL) specializes in engine production, gearbox construction, and automation. HIMMEL operates in the fields of machine and drive technology, control systems, plant construction, wastewater management, process engineering, and recycling. The firm also works in electrical & control engineering to develop and manufacture economical solutions for control and regulation systems. HIMMEL was certified by DIN EN ISO 9001.

HIMMEL provides standard and custom-made drum motors to be used in conveyor technology. The company provides drum motors for various applications such as fish processing, the food sector, wood processing, airport check-in areas, the furniture industry, the production of railroad sleepers, the packaging industry, film winders, and screening machines. Moreover, HIMMEL drum motors cater to the North America market.

Tianjin Seaparks Machinery-Electronics Co., Ltd

Established in 2002 and headquartered in Tianjin, China, Tianjin Seaparks Machinery-Electronics Co., Ltd (Seaparks) is a leading provider of drum motors. The company provides drum motors for belt conveyors and roller conveyors. It also manufactures drum motors that are suitable for mobile crushers and screeners, such as jaw crushers, impact crushers, and cone crushers. The company has a production capacity of 300,000 drum motors annually.

Additionally, the company’s AMROLL drum motors have been exported to more than 40 countries and find extensive application in airport baggage handling, security inspection machines, postal, parcel, food processing, pharmaceutical handling, and warehousing. Moreover, the company has customers across North America, South America, Asia, Europe, Africa, and Oceania.