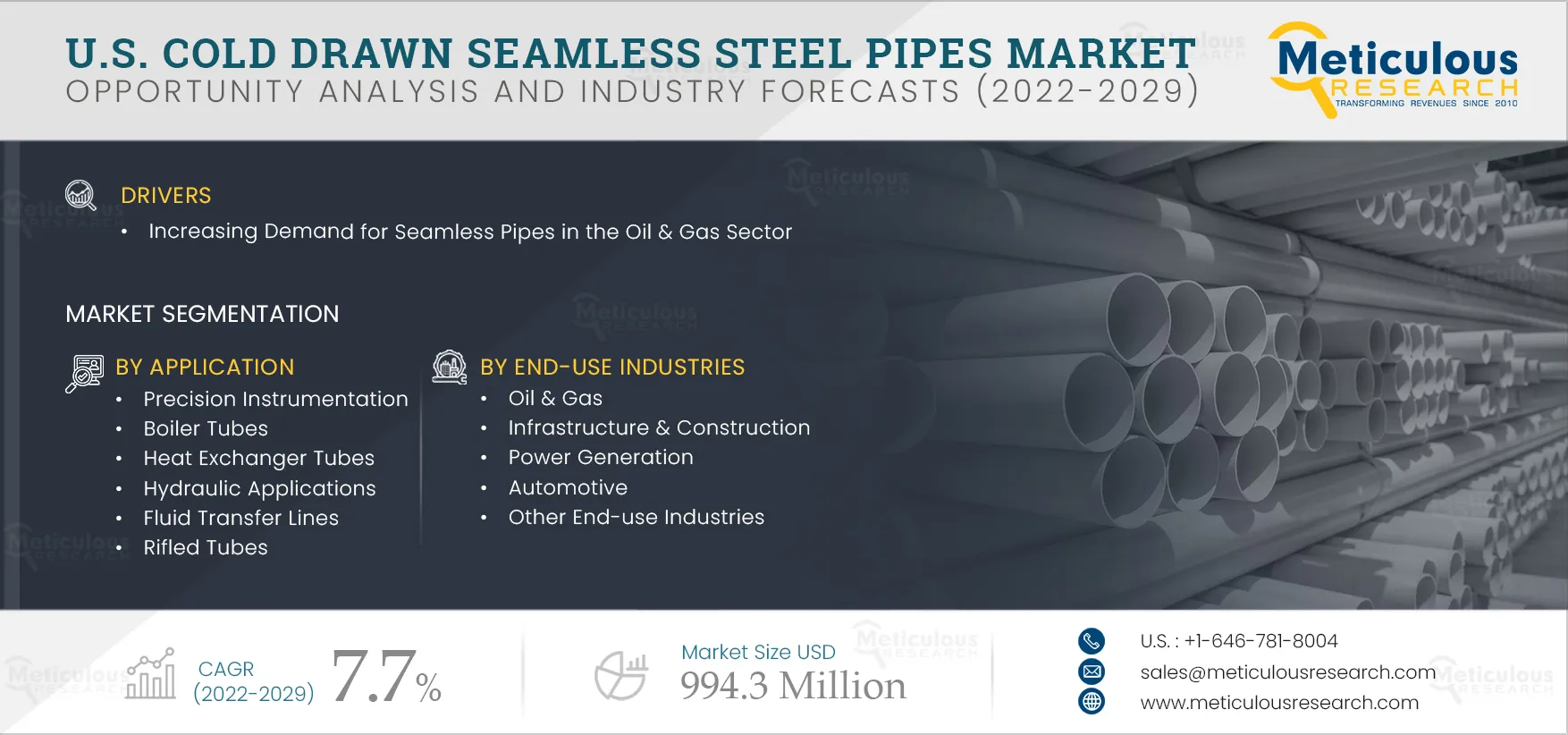

The U.S. Cold Drawn Seamless Steel Pipes Market is expected to grow at a CAGR of 7.7% from 2022 to reach $994.3 million by 2029. The increasing demand for seamless pipes in the oil & gas sector is the key factor driving the growth of the U.S. cold drawn seamless steel pipes market. However, the volatile raw material prices and lower demand in saturated markets are expected to restrain the growth of this market. Increased offshore spending and new oilfield discoveries are expected to create significant growth opportunities for the players operating in the U.S. cold drawn seamless steel pipes market. Trade protectionism and the introduction of new substitutes pose serious challenges to the growth of this market.

Here are the top 10 companies operating in the U.S. Cold Drawn Seamless Steel Pipes Market

American Piping Products Inc. (U.S.)

Founded in 1994 and headquartered in Missouri, U.S. American Piping Products Inc. is a supplier of carbon, specialty & chrome-moly pipes, tubes, and fittings & flanges used in the processing, energy, manufacturing, fabrication, and construction industries. American Piping provides a wide range of products, such as seamless carbon pipes, low temp pipes, alloy pipes & products, chrome moly pipes, welded pipes, seamless stainless-steel pipes, fittings & flanges, and specialty customized products.

The company’s offerings cater to various industries, such as power generation, oil field applications, gas and chemical processing, shipbuilding and pressure vessels, fabrication, and OEM. American Piping Products combines a large inventory and provides value-added services to different industries. The company provides various services, including cutting to length, project management, profiling, testing, beveling, threading, and protective coatings. Through its strong distribution network, the company has its presence across Houston (Texas) and Chicago (Illinois).

Chicago Tube and Iron Company (a part of Olympic Steel, Inc.) (U.S.)

Founded in 1914 and headquartered in Illinois, U.S. Chicago Tube, and Iron Company is engaged in the distribution of tubings, pipes, valves, and fittings. In May 2011, U.S. Olympic Steel, Inc. (U.S.) acquired all of the outstanding shares of Chicago Tube and Iron Company. The company provides a wide range of products, such as round mechanical tubing, aluminum pipe, tube & bar, square, rectangular & round tubing, carbon steel pipe, hydraulic tubing, valves & fittings, cold finished/hot roll bar, boiler tubing, stainless pipe, tube & bar, and ASME pressure parts.

The company offers various services, such as coiling, bending (hot/cold process), machining, welding (code/non-code), hydro testing, ASME stamps, swaging, press bending, laser tube processing, and CNC bending.

ArcelorMittal North America Holdings LLC (a part of Cleveland-Cliffs, Inc.) (U.S.)

Founded in 2016 and headquartered in Chicago, U.S., ArcelorMittal North America Holdings LLC provides a full range of steel products and solutions for various applications, including automotive, construction, energy, and appliances. ArcelorMittal North America Holdings LLC provides a wide range of products, such as flat-rolled steel, long steel, tubular products, and tailored blanks products. These products are manufactured using numerous processes, including hot rolled, cold rolled, hot-dip galvanized, drawn over mandrel, ERW (Electric resistance welded) tubing, drawn over mandrel, cold drawn seamless, and hot finish seamless.

In December 2020, Cleveland-Cliffs Inc. (U.S.) acquired all the operations of ArcelorMittal USA LLC, including its subsidiaries. Cleveland-Cliffs Inc. operates through four reporting segments: Automotive, Infrastructure and Manufacturing, Distributors and Converters, and Steel producers. ArcelorMittal North America Holdings LLC is an industry leader across all major market segments in North America. The company caters to various industries, including automotive, construction, energy, heavy equipment, pipe & tube, and transportation. As of December 2021, the company had a headcount of 25,000 employees.

Bison Stainless Tube, LLC (U.S.)

Founded in 2011 and headquartered in Texas, U.S. Bison Stainless Tube, LLC offers stainless-steel hypodermic & fractional tubing to OEMs & contract manufacturers in industries, including medical, aerospace, instrumentation, nuclear, industrial, and oil & gas. The company’s offerings include hypodermic tubing, fractional tubing, metric tubing, medical tubing, pipe, and customized products. The company offers services such as electrochemical, deburring, cold sawing, abrasive cutting, electropolishing, passivation, assemblies, bending, swaging, drilling, flaring, forming, threading, turning, centerless grinding, and brazing.

Penn Stainless Products, Inc. (U.S.)

Founded in 1949 and headquartered in Pennsylvania, U.S. Penn Stainless Products, Inc. supplies specialty stainless steel, high-temperature stainless grades, corrosion-resistant stainless grades, and duplex materials—in multiple product forms, including stainless steel sheet, plate, bar, tubular and structural. The company offers over 30 grades of stainless steel, including 300 and 400 series stainless, duplex steels, 17-4PH, and high-temperature grades, for shipments worldwide. The company offers an extensive array of advanced and standard stainless-steel processing services for plate & sheet processing (machine cutting, plate shear cutting, plasma cutting, dynamic waterjet cutting, saw cutting, gauer processing, sheet leveling, plate leveling, polishing, blanchard grinding, laser cutting), and long product processing (production cutting, long product cutting, bar & structural cutting, polishing).

U.S. Steel Tubular Products Inc. (a part of United States Steel Corporation) (U.S.)

Founded in 1901 and headquartered in Pennsylvania, U.S., U. S. Steel Tubular Products Inc. is a leading steel producer. U. S. Steel Tubular is a subsidiary of United States Steel Corporation and offers steel tubular products for the oil & gas industry. The company’s oil country tubular goods products (OCTG) category offers a broad range of OCTG products and services, such as OCTG casings and tubings, OCTG steel grades, OCTG connections, OCTG casing & tubing accessories, OCTG casing & tubular services, and rig site services.

The company also offers seamless standard and line steel pipe products, high-frequency electric weld (ERW) line pipe and standard products, API 5L line pipes, A106 seamless carbon steel pipes, A252 piling pipes, A53 seamless and welded standard pipes, and A523 cable circuit piping. These products are widely used throughout the energy sector, both upstream and downstream. The company offers both seamless and high-frequency electric welded pipes as per specific requirements for applications in exploration and production activities, pipelines, construction, refining, and chemical and petrochemical facilities.

Bri-Steel Manufacturing (Canada)

Founded in 2010 and headquartered in Edmonton, Canada. Bri-steel Manufacturing is engaged in the production of large diameter seamless steel pipes in Canada. Bri-Steel produces pipes ranging from outside diameters of 16 inches through 36 inches and wall thicknesses up to 2.343 inches in CSA, ASTM, ASME, and API specifications. The company offers various pipe manufacturing processes such as thermal pipe expansion, straightening, cropping, destructive testing, pipe de-scaling, non-destructive testing, hydro testing, beveling, and coating.

Michigan Seamless Tube, LLC (U.S.)

Founded in 1927 and headquartered in Michigan, U.S. Michigan Seamless Tube, LLC. offers a full line of mechanical and pressure products to ASTM, ASME, and API, including heat exchangers, condensers, boilers, IPS pressure pipes, and oil production tubulars to serve the distribution, transportation, energy, heavy equipment, and OEM sectors. The company provides a wide range of products, such as boiler tubes, pipes, and mechanical tubes. The company’s offerings cater to various industries, such as aerospace & aircraft, automotive & transportation, heavy equipment, agriculture, and OCTG.

Founded in 1980 and headquartered in Houston, U.S. U.S. Metals, Inc. offers piping components for refineries, petrochemical plants, power plants, and other related industries. The company’s offerings include chrome alloy, stainless steel, nickel, HF alkylation, low-temperature products, and specialty metals. The company’s offerings cater to various industries, such as global power generation, oil refineries, and gas & chemical processing.

Industrial Tube and Steel Corporation (U.S.)

Founded in 1956 and headquartered in Ohio, U.S. Industrial Tube and Steel Corporation is a provider of a wide range of continuous cast iron bars, mechanical steel & structural tubings, carbon steel pipes (seamless & welded), turned, ground, and polished (TG&P) bars, steel cutting and & sawing services, and different types and grades of steel & iron. The company caters to various sectors, including construction & heavy equipment, agriculture, infrastructure, fluid handling, machinery, oil & gas, general machining & fabrication, automotive & transportation, energy, and material handling.