Resources

About Us

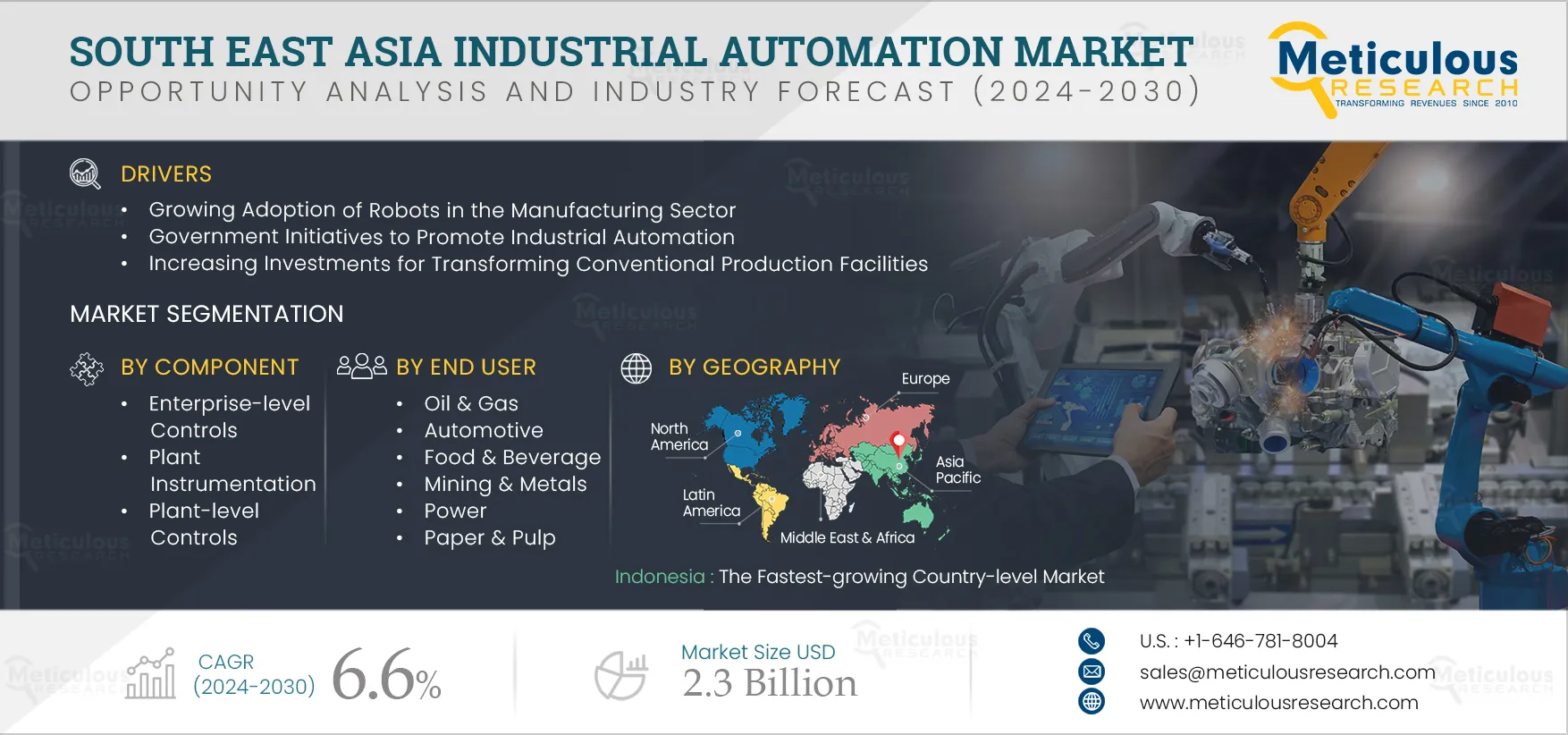

South East Asia Industrial Automation Market by Component (Plant-level Controls, Enterprise-level Controls, Plant Instrumentation), Mode of Automation, End User, and Geography - Forecast to 2032

Report ID: MRICT - 104902 Pages: 350 Jan-2025 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportThe South East Asia Industrial Automation Solutions Market is projected to reach $2.3 billion by 2032, at a CAGR of 6.6% from 2025 to 2032. The growth of this market is driven by the growing adoption of robots in the manufacturing sector, government initiatives to promote industrial automation solutions, and increasing investments in transforming conventional production facilities. The growing number of SMEs and rising demand for IIoT in South East Asia's manufacturing sector are expected to offer significant growth opportunities for the stakeholders in the South East Asia industrial automation market. The high initial investment may restrain the market's growth. Furthermore, the limited availability of skilled labor and cyber risks associated with automated systems are expected to challenge the growth of the South East Asia industrial automation market.

The adoption of industrial robots has increased exponentially during the last decade due to their benefits, such as high productivity, consistent speed & quality, improved workplace safety, and better floor space utilization. Many industries, such as healthcare, agriculture, food & beverage, manufacturing, and processing, use robots to perform critical and time-consuming tasks.

Click here to: Get a Free Sample Copy of this Report

The automotive industry uses industrial robots for assembly line applications such as welding, painting, assembly, pick & place, packaging & labeling, and product inspection. The automobile industry uses industrial robots throughout its assembly line. These applications of industrial robots include welding, painting, assembly, pick and place, packaging and labeling, and product inspection. Robots provide numerous benefits in metal and plastic manufacturing, including improved efficiency, precision, and quality. They can perform tasks such as welding, cutting, machining, and molding with high accuracy and repeatability, ensuring consistent production of high-quality parts.

Robots are also entering new markets, including textiles, wood products, and plastics. Hence, the increasing adoption of robots in the manufacturing sector is boosting the demand for industrial automation solutions, driving the growth of this market. Further, the exerting efforts by companies to use robots for manufacturing across South East Asian countries are supporting the market's growth. For instance, in May 2020, Hyundai Robotics Co., Ltd. (South Korea) signed a deal to supply 370 vehicle manufacturing robots to the Hyundai Motors Indonesian automotive plant in Jakarta, Indonesia. Hyundai Robotics plans to supply vehicle manufacturing robots and peripherals and proceed with the construction on a turnkey basis, from installing to test driving and more in Hyundai Motors' new Indonesian plant (Deltamas Industrial Complex) by 2022. Such development is expected to support the growth of the market.

Based on Component, the Plant-level Controls Segment is Projected to Register the Highest CAGR During the Forecast Period

The growth of this segment is driven by the increasing need to improve the productivity of manufacturing/industrial engineers across the industries, the growing need to enhance supply chain operations, maintenance management, data collection, and product configurations, increasing implementations of SCADA to control and optimizes industrial operations, and increasing deployments of HMI for displaying data, tracking production time and trends, and monitoring machine inputs and outputs.

Based on Mode of Automation, the Fully-automatic Systems Segment is Projected to Register the Highest CAGR During the Forecast Period

The growth of this segment is driven by the growing need to increase industrial production capabilities. Adopting fully-automatic systems helps companies increase their throughput volumes by automating the feeding and assembly processes. The companies adopting fully-automatic systems are usually large-scale companies with automated equipment in their operating facilities and are exploring ways to minimize long-term costs by reducing human labor.

Based on End User, the Automotive Segment is Projected to Register the Highest CAGR During the Forecast Period

The growth of this segment is driven by the increasing implementation of machine vision systems and sensor technologies by automotive manufacturers, increasing utilization of robotics for automotive body assembly automation, including streamlining repetitive processes like welding, material handling, and assembling auto body components, and intelligent automation for enhanced manufacturing flexibility. Automotive manufacturers can save on labor costs and rework, improving quality and repeatability with robotics, vision, and software integration.

Indonesia: The Fastest-growing Country-level Market

Indonesia is projected to register the highest CAGR during the forecast period. The presence of well-established South East Asia industrial automation solution providers, reduced cost of automation systems, increasing investment by foreign companies for industrial automation, increasing labor cost, and increasing safety and hygiene requirements in the industrial sector are improving the demand for industrial automation solutions, in turn supporting the growth of the market. Further, the growing technological advancements in industrial sensors and rapid expansion of the industrial manufacturing sector across the country are improving the demand for industrial automation solutions, supporting the growth of this market.

Key Players:

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by leading market participants in the last 3–4 years. The key players operating in the South East Asia industrial automation market are ABB Ltd. (Switzerland), Rockwell Automation Inc. (U.S.), Siemens AG (Germany), Yaskawa Electric Corporation (Japan), Schneider Electric SE (France), Yokogawa Electric Corporation (Japan), KUKA AG (Germany), Emerson Electric Co. (U.S.), FANUC CORPORATION (Japan), Honeywell International Inc. (U.S.), Mitsubishi Electric Corporation (Japan), OMRON Corporation (Japan), Advantech Co., Ltd. (Taiwan), Fuji Electric Co., Ltd. (Japan), and General Electric Company (U.S.).

Scope of the Report:

South East Asia Industrial Automation Solutions Market Assessment, by Component

South East Asia Industrial Automation Solutions Market Assessment, by Mode of Automation

South East Asia Industrial Automation Solutions Market Assessment, by End User

South East Asia Industrial Automation Solutions Market Assessment, by Country/Region

Key questions answered in the report:

The South East Asia Industrial Automation Solutions Market is projected to reach $2.3 billion by 2032, at a CAGR of 6.6% from 2025 to 2032

The plant-level controls segment is projected to register the highest CAGR during the forecast period due to the increasing need to improve the productivity of manufacturing/industrial engineers across the industries, the growing need to enhance supply chain operations, maintenance management, data collection, and product configurations, and increasing implementations of SCADA to control and optimizes industrial operations.

The fully-automatic systems segment is projected to register the highest CAGR during the forecast period due to the growing need to increase industrial production capabilities, the adoption of fully-automatic systems to increase throughput volumes by automating the feeding and assembly processes, and the growing need to minimize long-term costs by reducing human labor.

The growth of this market is driven by the growing adoption of robots in the manufacturing sector, government initiatives to promote industrial automation, and increasing investments in transforming conventional production facilities. The growing number of SMEs and rising demand for IIoT in South East Asia's manufacturing sector are expected to offer significant growth opportunities for the stakeholders in the South East Asia industrial automation market.

The key players operating in the South East Asia industrial automation market are ABB Ltd. (Switzerland), Rockwell Automation Inc. (U.S.), Siemens AG (Germany), Yaskawa Electric Corporation (Japan), Schneider Electric SE (France), Yokogawa Electric Corporation (Japan), KUKA AG (Germany), Emerson Electric Co. (U.S.), FANUC CORPORATION (Japan), Honeywell International Inc. (U.S.), Mitsubishi Electric Corporation (Japan), OMRON Corporation (Japan), Advantech Co., Ltd. (Taiwan), Fuji Electric Co., Ltd. (Japan), and General Electric Company (U.S.).

The market in countries such as Indonesia, Singapore, Thailand, the Philippines, and Malaysia are expected to witness strong growth in the coming years and offer significant growth opportunities for market players.

Published Date: Jan-2025

Published Date: Jan-2025

Published Date: Jan-2025

Published Date: Jan-2025

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates