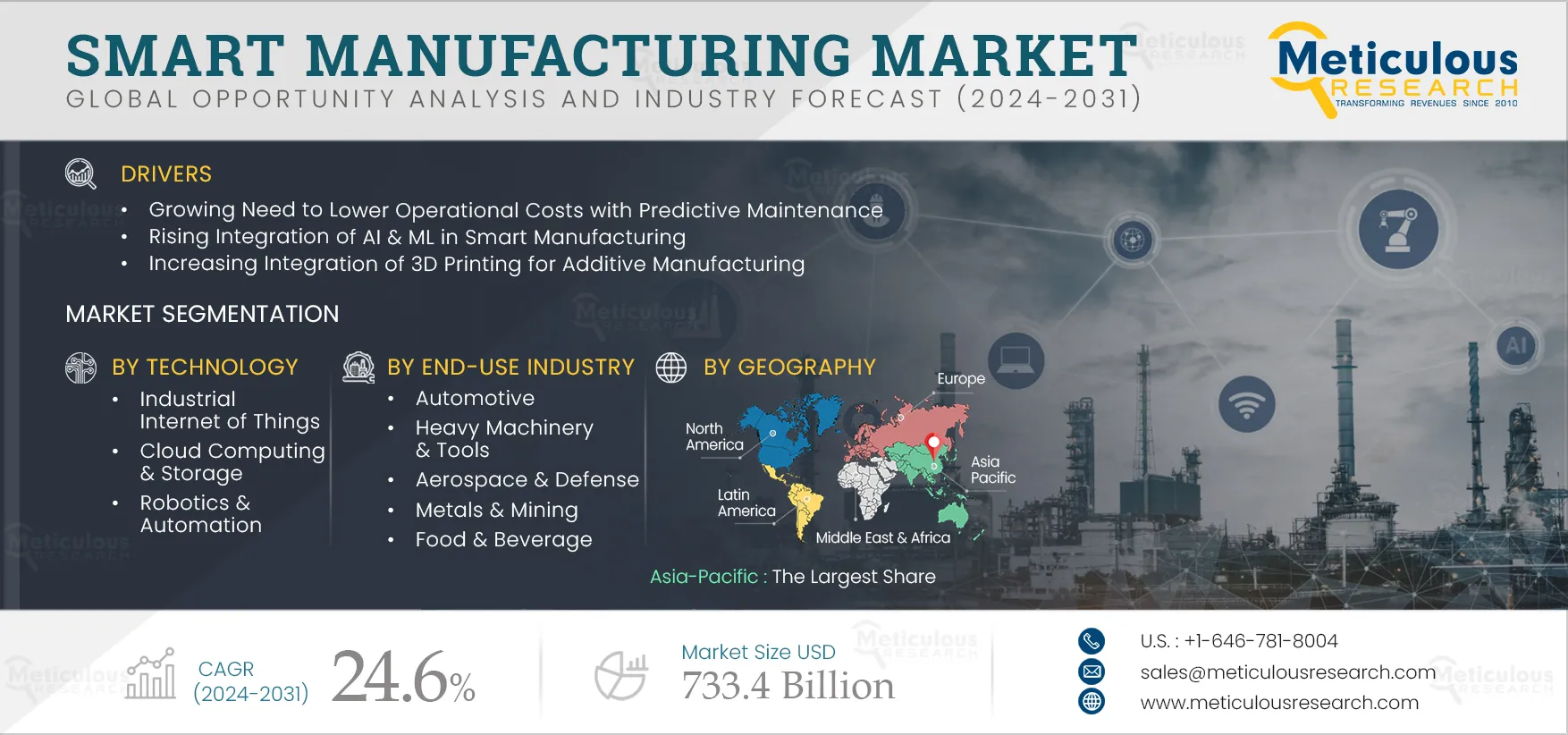

The Smart Manufacturing Market is expected to grow at a CAGR of 24.6% from 2024 to reach $733.4 billion by 2031. The growth of the smart manufacturing market is majorly attributed to the growing government initiatives to promote industrial automation, rising investments toward Industry 4.0, growing demand for safety regulation compliance, and high labor costs in developed economies. In contrast, high capital and operating expenses and a lack of standardization for technology platforms are some of the major factors restraining the growth of this market.

Here are the top 10 companies operating in Smart Manufacturing Market

Schneider Electric SE (France)

Founded in 1836, headquartered in France. Schneider Electric SE is a global specialist in energy management and automation solutions. The company provides end-point to cloud integration connecting products, controls, software, and services. The company accelerates digital transformation for buildings, infrastructure, and industry to enable a smart and green future. The company focuses on partnerships with world-leading independent software companies to bring energy management and automation digitization solutions. It offers universal automation and software-centric automation solutions.

With its subsidiaries and a strong distribution network, the company has its presence across North America, Western Europe, Asia-Pacific, and other countries. Some of its subsidiaries are Square D (U.S.), Schneider Canada, Inc. (Canada), Schneider Electric (Australia) Pty Ltd. (Australia), ProLeiT Group (Germany), and AB Wibe (Sweden).

ABB Ltd. (Switzerland)

Founded in 1988, headquartered in Switzerland. ABB Ltd. is a pioneering technology leader that works closely with utility, industry, transportation, and infrastructure customers. The company operates mainly in robotics, power, heavy electrical equipment, and automation technology. The company operates in the market through four segments namely, Electrification Motion, Process Automation, Robotics & Discrete Automation. The company provides industry-specific integrated automation, electrification, and digital solutions, control technologies, software, and advanced services, as well as measurement & analytics and marine and turbocharging offerings through its Process Automation segment. ABB’s smart manufacturing solutions enable fully-integrated, collaborative manufacturing systems that respond in real-time to meet the changing demands and conditions in the smart factory, supply network, and customer needs.

Cognex Corporation (U.S.)

Founded in 1981, headquartered in U.S. Cognex Corporation is a leading worldwide provider of machine vision products that capture and analyze visual information to automate manufacturing and distribution tasks where vision is required. The company offers a full range of machine vision systems and sensors, vision software, and industrial image-based barcode readers. It also offers products ranging from low-cost vision sensors that conduct simple presence/absence inspections to deep learning solutions. Machine vision products are designed to automate the manufacturing and tracking of discrete items during the manufacturing or distribution process. Cognex offers products for a broad range of customers across various industries, including logistics, automotive, consumer electronics, medical-related, semiconductor, consumer products, and food & beverage.

With its subsidiaries and a strong distribution network, the company has its presence across the Americas, Europe, Greater China, and other Asian counties. Some of its subsidiaries are Sualab Co., Ltd. (South Korea), Webscan Inc. (U.S.), EnShape GmbH (Germany), Cognex UK Ltd (U.K.), and Cognex Korea Inc (South Korea).

Founded in 1847, headquartered in Germany. Siemens AG is a technology company that focuses on industry, infrastructure, transport, and healthcare. The company is active globally and focuses on automation and digitalization in the process and manufacturing industries, intelligent infrastructure for buildings and distributed energy systems, smart mobility solutions for rail and road, and medical technology & digital healthcare services. Siemens smart manufacturing solutions create an intelligent production environment through visualization, data analytics, and the ability to share information digitally across the manufacturing ecosystem. The company provides digital twins, cloud solutions, and automation solutions for the manufacturing and processing industries.

With its subsidiaries and a strong distribution network, the company has its presence across Europe (excluding Germany), C.I.S., Africa, the Middle East, the Americas, Asia, and Australia. Some of its subsidiaries are Siemens Healthineers AG (Germany), Siemens Canada Limited (Canada), Mentor Graphics (U.S.), Siemens Financial Services (Germany), and Siemens Digital Logistics GmbH (Germany).

Emerson Electric Co. (U.S.)

Founded in 1890, headquartered in U.S. Emerson Electric Co. is a global leader that designs and manufactures automation products and delivers services for a wide range of industrial, commercial, and consumer markets. The company provides smart manufacturing solutions in several categories, including augmented reality products, measurement & instrumentation products, operations management software, automation & control software, valves, actuators & regulators, control and safety systems, welding, assembly and cleaning, and automation services. The company also offers smart manufacturing solutions for various industries, such as life sciences, power generation & transmission, energy, cold chain, and food & water.

With its subsidiaries and a strong distribution network, the company has its presence across the Americas, Europe, and Asia, and the Middle East & Africa. Some of its subsidiaries are Rosemount Inc. (U.S.), Roxar AS (Norway), Anderson Greenwood Crosby (U.S.), Greenlee (U.S.), Knurr AG (Germany), and Open Systems International, Inc. (U.S.).

Cisco Systems, Inc. (U.S.)

Founded in 1984, headquartered in U.S. Cisco System, Inc. is a leading provider of industrial networking and smart manufacturing solutions. The company designs and sells a wide range of technologies that power the internet. The company’s products and technologies are grouped into the following categories: Infrastructure Platforms, Applications, Security, and Other Products. In addition to its product offerings, the company provides a broad range of services, including technical support services and advanced services. The company provides its solutions and services across several verticals, such as public institutions, governments, and service providers, including large webscale providers. Cisco’s IoT solutions enable customers to build a robust network to harness optimal value from connected factory initiatives.

With its subsidiaries and a strong distribution network, the company has its presence across the Americas, EMEA, and APJC. Some of its subsidiaries are Cisco Webex (U.S.), Cisco Meraki (U.S.), OpenDNS (U.S.), AppDynamics (U.S.), Jabber, Inc (U.S.), and vIPtela Inc (U.S.)

PTC, Inc. (U.S.)

Founded in 1985, headquartered in U.S. PTC Inc. is a global software and services company that provides digital transformation. It provides digital technology solutions to enable industrial digital transformation across the engineering, manufacturing, and service sectors. The company offers solutions for innovative manufacturers in the aerospace & defense, automotive, electronics & high tech, industrial machinery & equipment, life sciences, oil & gas, retail, and consumer products industries. The company divided its business into two key product groups: Digital Thread and Velocity.

With its subsidiaries and a strong distribution network, the company has its presence across the Americas, Europe, and Asia-Pacific. Some of its subsidiaries are Atego Group Ltd. (U.K.), Atego Systems Ltd. (U.K.), Parametric Holdings (UK) Limited (U.K.), Parametric Korea Co., Ltd. (South Korea), and Parametric Technology (India) Private Ltd. (India)

Amazon Web Services, Inc. (U.S.)

Founded in 1994, headquartered in U.S. Amazon Web Services, Inc. (AWS) is a global provider of smart manufacturing solutions. For more than 25 years, the company has been designing and manufacturing smart products using cutting-edge automation, machine learning and AI, and robotics, with AWS at its core. The company provides cloud solutions in several areas such as product & production design, smart factories, and smart products & services. The company provides smart manufacturing solutions for automotive, consumer packaged goods, pharmaceutical, and semiconductor industries. Amazon’s smart factory products leverage AWS IoT Services, edge computing, data lakes, and advanced analytics tools to improve manufacturing operations.

With its subsidiaries and a strong distribution network, the company has its presence across the U.S., Germany, the U.K., Japan, and other countries. Some of its subsidiaries are CloudEndure (U.S.), Elemental Technologies LLC (U.S.), TeamSQL, Inc. (Turkey), Peritor GmbH (Germany), TSO Logic, Inc. (U.S.), and Thinkbox Software Inc. (U.S.).

SAP SE (Germany)

Founded in 1972, headquartered in Germany. SAP SE is a global provider of Industrial IoT platforms. The company provides industrial manufacturing solutions, smart factory solutions, SAP manufacturing software, and Industrial Internet of Things (IIoT) solutions. The company implements Industry 4.0 solutions powered by the Industrial Internet of Things (IIoT) and cyber-physical systems-smart, autonomous systems to monitor and control objects such as machinery, robots, and vehicles. It delivers configurable, sustainable, and smart machinery and components with industrial manufacturing solutions. The company also develops smart manufacturing solutions using technologies such as Cloud connectivity, Artificial intelligence, Machine learning, Big Data, Industrial Internet of Things (IIoT), Digital twins, Additive printing, Virtual reality (VR) and augmented reality (AR), Blockchain, and Modern databases (In-memory databases and modern ERP systems).

With its subsidiaries and a strong distribution network, the company has its presence across EMEA, Americas, and APJ. Some of its subsidiaries are Ariba Inc. (U.S.), Taulia Inc. (U.S.), Taulia UK Ltd (U.K.) SAP Signavio (Germany), SAP Hybris (Germany), and SAP Japan Co., Ltd. (Japan).

Robert Bosch Manufacturing Solutions GmbH (a subsidiary of Robert Bosch LLC) (Germany)

Founded in 1986, headquartered in Germany. Robert Bosch Manufacturing Solutions GmbH is a global supplier of special purpose machinery. The company offers individual assembly and automation solutions, advanced process technology, and services along the entire product life cycle. The company offers solutions based on the Internet of Things (IoT) to make manufacturing more efficient. It offers intelligent automation solutions for production in several areas, such as machinery, processes & technologies, intelligent solutions, and services. The company is a system integrator and general contractor of various assembly systems, consisting of building systems, single process systems, and conveyor systems. The company also offers innovative processes and technologies for the manufacturing of high-quality products.

With its subsidiaries and a strong distribution network, the company has its presence across Europe, the Americas, Asia-Pacific, Europe, and the Middle East & Africa. Some of its subsidiaries are Bosch Rexroth AG (Germany), BSH Hausgerate GmbH (Germany), Bosch Power Tools B.V. (U.S.), ETAS GmbH (Germany), and Bosch Thermotechnik GmbH (Germany).