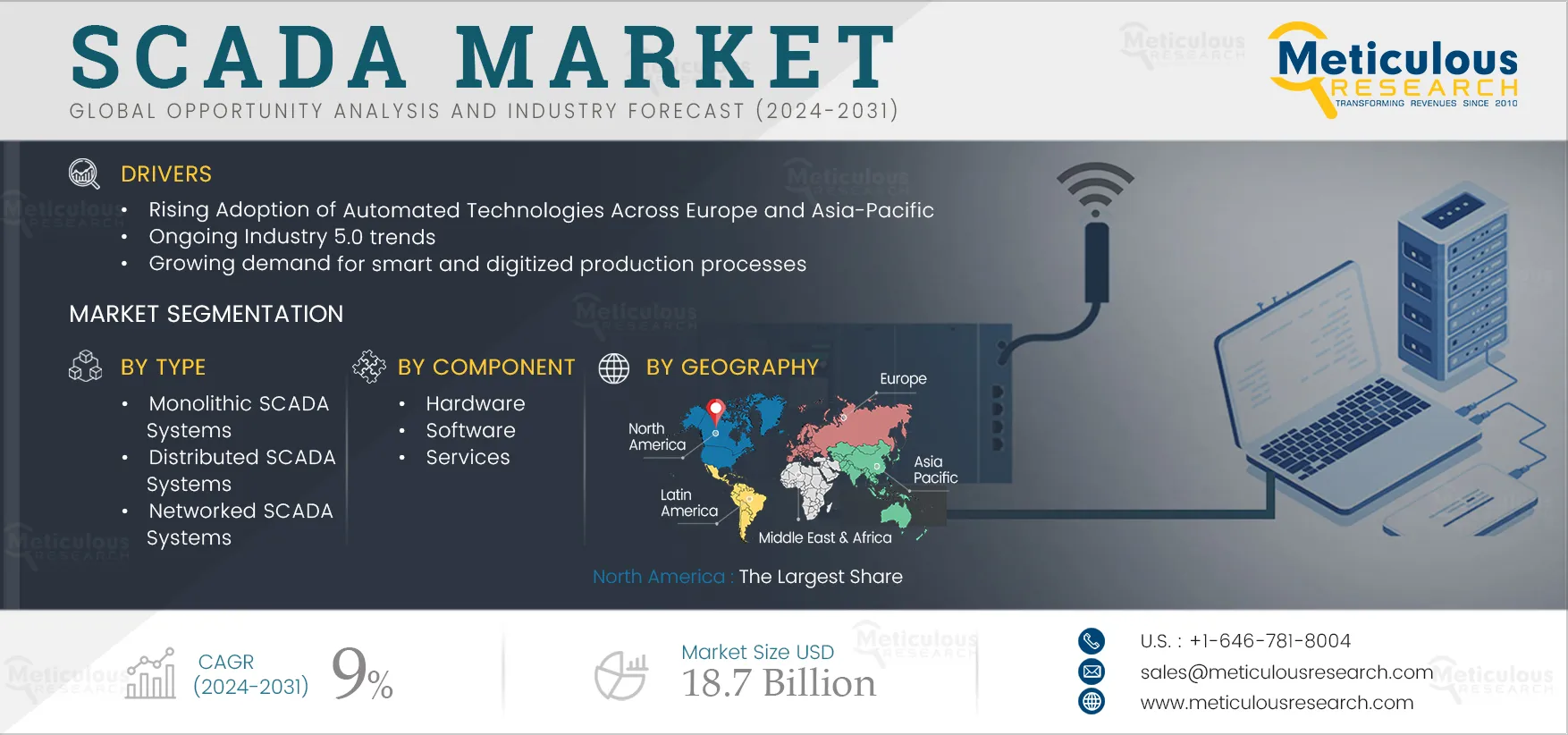

The SCADA Market is expected to reach USD 18,675.4 million by 2031 from an estimated USD 10,213.6 million in 2024, at a CAGR of 9% during the forecast period 2024–2031. Factors such as the rising adoption of automated technologies across Europe and Asia-Pacific, the ongoing Industry 5.0 trends, growing demand for smart and digitized production processes, and government support and initiatives for industrial automation are driving the growth of the SCADA market. However, high initial investment requirements are restraining the growth of this market.

Furthermore, the increasing trend of wireless sensor networks and the proliferation of smart factories are expected to create growth opportunities for the players operating in this market. However, the high risk of cyberattacks is a major challenge impacting market growth.

Here are the top 10 companies operating in the SCADA Market

Schneider Electric SE is a digital automation and energy management company. The company provides various products for different applications, including residential and small businesses, building automation and control, low voltage products and systems, solar and energy storage, access to energy, medium voltage distribution and grid automation, critical power, cooling and racks, and industrial automation and control. The company caters to different end-use industries, including automotive and eMobility, cloud and service providers, commercial real estate, data center and network solutions, energies and chemicals, facility management, food and beverage, healthcare, hotels, industrial automation solutions, life sciences, logistics and warehouse, machinery, marine, mining, and minerals and metals. The company offers sustainable and efficient smart packaging machines with EcoStruxure solutions.

Siemens AG

Siemens AG offers power and energy solutions for building technology, drive technology, energy, healthcare, industrial automation, mobility, financing, consumer products, and services. Siemens focuses on areas such as automation, digitalization in the process and manufacturing industries, intelligent infrastructure for buildings and distributed energy systems, conventional and renewable power generation, and power distribution, smart mobility solutions for rail and road, and medical technology and digital healthcare services. The company provides a wide range of products, such as SIMATIC SCADA, PLCs, HMI (Human-Machine Interface), communication modules, compact RTUs, distributed control systems, and process control systems.

Rockwell Automation, Inc. provides industrial automation solutions and digital transformation technologies. The company provides a SCADA software suite that is designed to provide comprehensive visualization and control of manufacturing processes. Rockwell Automation offers SCADA solutions and hardware for a wide range of end-use industries such as aerospace, automotive, chemical, food & beverage, oil & gas, power generation, pulp & paper, semiconductors, and water & wastewater. The company operates through three business segments: Intelligent Devices, Software & Control, and Lifecycle Services. Rockwell Automation offers a variety of solutions and hardware for SCADA systems, such as Analytics & Data Management Software, Design Software, Performance Monitoring Software, human-machine interface, and PLC programmable controllers.

ABB Ltd

ABB is a technology company that offers solutions to utility, industrial, transportation, and infrastructure sectors. The company primarily operates in robotics, power, heavy electrical equipment, and automation technology. The company provides various products such as control room solutions, drives, electric vehicle charging infrastructure, industrial software, low voltage products and systems, measurement and analytics, medium voltage products, metallurgy products, motors and generators, PLC automation, power converters and inverters, and robotics. The company also provides packaging solutions for its medium-voltage products.

ABB caters to different industries, including aluminum, automotive, buildings and infrastructure, cement, channel partners, chemicals, data centers, food & beverage, life sciences, marine, metals, mining, oil and gas, ports, power generation, printing, process automation, pulp and paper, and railways.

Mitsubishi Electric Corporation

Mitsubishi Electric Corporation is a leading company in the manufacture and sales of electrical and electronic products and systems used in a broad range of fields and applications. The company operates in the market through six reportable segments: Life, Industry and Mobility, Infrastructure, Semiconductor & Device, Business Platform, and Others.

The company offers programmable logic controllers, servomotors, CNC (computerized numerical controllers), human-machine interfaces, inverters, industrial robots, motors, magnetic switches, transformers for electricity distribution, software, and others through its Factory Automation Systems business (a part of Industry and Mobility). Mitsubishi’s MC Works64 provides a highly functional monitoring control system in response to various business needs in manufacturing, production processes, or the office. MC Works64 proposes solutions to various issues concerning monitoring control.

Omron Corporation

OMRON Corporation manufactures automation equipment and systems for computer, communication, and control technology. OMRON’s business fields cover a broad spectrum, ranging from industrial automation and electronic components to social systems, including automated ticket gates, solar power conditioners, and healthcare. The company has innovative production floors with cutting-edge technologies and unique services based on the widest range of control devices for factory automation to contribute to advancing productivity in the world’s manufacturing industry.

The company operates through four business segments: Industrial Automation Business (IAB), Healthcare Business (HCB), Device & Module Solutions Business (DMB), and Social Systems, Solutions and Service Business (SSB). The company offers a wide range of automation systems products, such as programmable logic controllers, automation software, and human-machine interfaces (HMI).

Yokogawa Electric Corporation provides industrial automation and test and measurement solutions. The company’s industrial automation and control business has contributed to the development of a wide range of industries with its distributed control systems for the monitoring and control of plant production facilities. The company operates in the market through three reportable segments: industrial automation and control; measuring instruments, and new business and others.

The company is leading the evolution of supervisory control and data acquisition (SCADA) systems to advanced automation and information visualization solutions that span global enterprises. Yokogawa’s SCADA applications combine performance, availability, broad scalability, and platform independence to maximize return on investment (ROI) while minimizing the total cost of ownership (TCO) over the entire system lifecycle. The company has designed FAST/TOOLS to enable the most effective transfer of data and knowledge. FAST/TOOLS is a complete SCADA software environment. Yokogawa’s Enterprise Pipeline Management Solution (EPMS) provides a comprehensive series of standard software applications that are integrated within the FAST/TOOLS real-time system platform to facilitate pipeline management and operations. The company’s PLCs offer the fastest update rates for high-speed applications and are electrically and environmentally robust.

Honeywell International Inc.

Honeywell International Inc. offers technology solutions to address challenges around energy, safety, security, air travel, productivity, and global urbanization. The company is a pioneer in automation control, instrumentation, and services for the oil and gas, refining, energy, pulp and paper, industrial power generation, chemicals and petrochemicals, biofuels, life sciences, and metals and mining industries. The company operates in the market through four reportable segments: Aerospace, Honeywell Building Technologies, Performance Materials and Technologies, and Safety and Productivity Solutions.

Honeywell offers a wide range of control & supervisory systems to deliver integrated process control and advanced safety with better lifecycle support to protect and future-proof users’ investments. The company’s Experion SCADA is a powerful software platform incorporating technology for human-machine interface (HMI) and supervisory control and data acquisition (SCADA). Experion is a highly proven and complete SCADA solution that provides a single pane of glass for viewing and controlling single sites or fleets of new and existing assets.

Emerson Electric Co. designs and manufactures products and provides solutions for customers in a wide range of industrial, commercial, and consumer markets around the world. The company offers control and safety systems to help provide a safer, more environmentally efficient manufacturing process. The company operates in the market through four reportable segments: Automation Solutions, AspenTech, and Commercial & Residential Solutions.

The Automation Solutions segment offers a broad array of products, integrated solutions, software, and services that enable process, hybrid, and discrete manufacturers to maximize production, protect personnel and the environment, reduce project costs, and optimize their energy efficiency and operating costs. Emerson offers a wide range of control & safety systems, including Distributed Control Systems (DCS), and SCADA Systems, Programmable Automation Control Systems (PLC/PAC).

Hitachi Ltd.

Hitachi Ltd is active in a range of industries, including digital systems, power and renewable energy solutions, railway systems, healthcare products, and financial systems. The company operates through seven business segments, namely Connective Industries, Green Energy & Mobility, Digital Systems & Services, Automotive Systems, Hitachi Metals, Hitachi Construction Machinery and Others. Hitachi offers comprehensive solutions that integrate hardware, software, and services to enable real-time monitoring and control of critical infrastructure and industrial processes. Leveraging advanced technologies such as IoT, AI, and data analytics, Hitachi’s SCADA systems provide enhanced visibility, efficiency, and reliability for sectors such as energy, utilities, transportation, and manufacturing. With a focus on innovation and customer-centricity, Hitachi continues to drive advancements in SCADA technology, empowering organizations to optimize operations and achieve greater productivity and resilience.