Resources

About Us

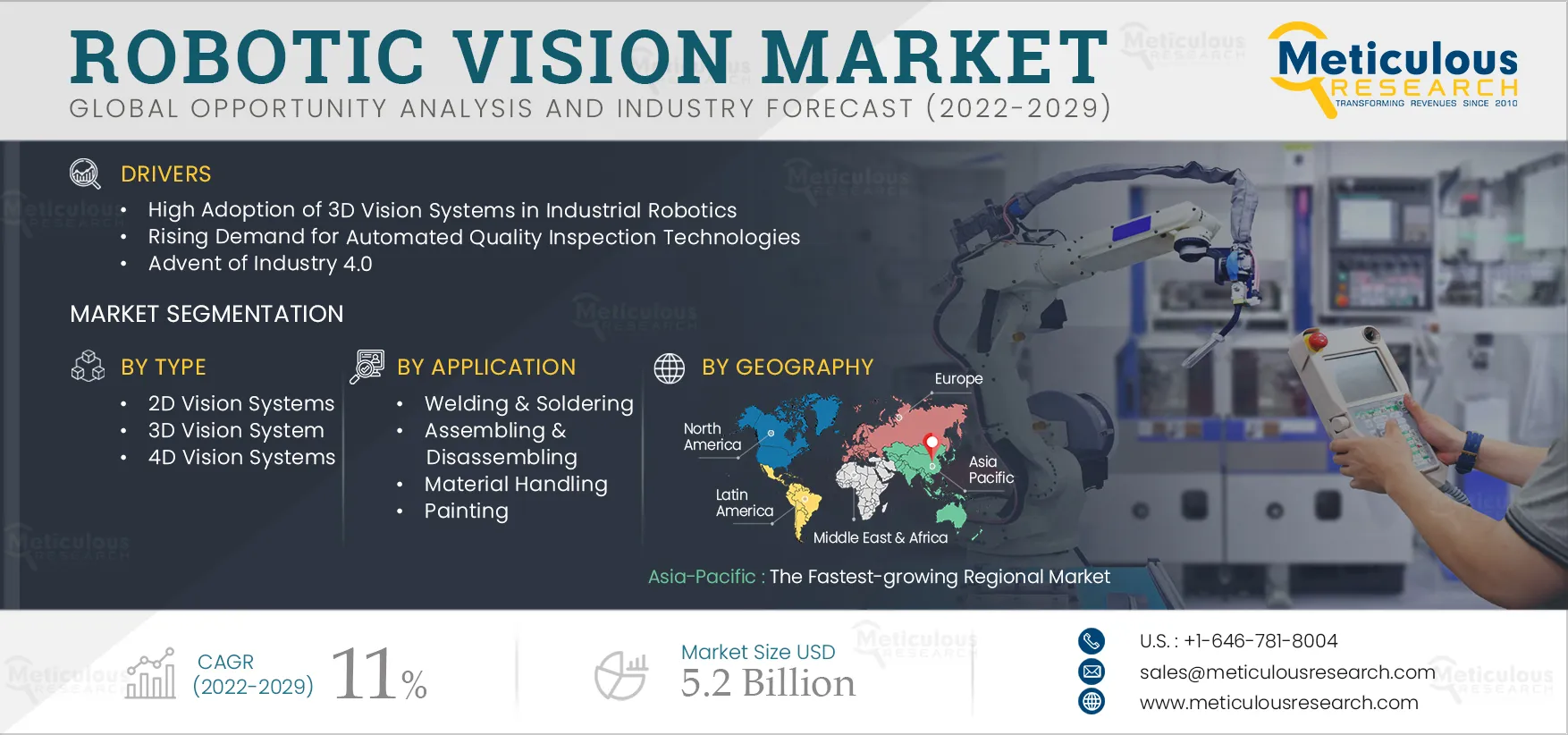

Robotic Vision Market by Offering, Type (2D, 3D, 4D), Application (Welding & Soldering, Assembling & Disassembling, Material Handling, Identification & Feature Extraction), End User (Industrial, Commercial), and Geography - Global Forecast to 2029

Report ID: MRSE - 104724 Pages: 360 Nov-2022 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportThe Robotic Vision Market is expected to reach $5.2 billion by 2029, at a CAGR of 11% during the forecast period of 2022–2029. The growth of this market is mainly driven by factors such as the increasing adoption of 3D vision systems in industrial robotics, the advent of industry 4.0, and the rising demand for automated quality inspection technologies. In addition, increasing government initiatives to support industrial automation and the growing deployment of machine vision systems across various end-use industries are expected to offer significant opportunities for the growth of this market.

However, the high initial installation cost restrains the growth of this market. Additionally, the use of AI & machine learning and the rising adoption of embedded vision are the major trends in this market.

Impact of COVID-19 on the Robotic Vision Market

The COVID-19 pandemic impacted the global economy. However, the outbreak accelerated the development and implementation of automation technologies. During the pandemic, automotive manufacturers got a chance to restructure their strategies to implement new technologies into existing infrastructure. Technologies such as 3D robot vision were installed on a considerable scale which helped major value chain holders from 3D robot vision to gain multiple contacts from different automakers.

Robotic vision systems played a positive role during the pandemic by providing machine vision technologies, including automated lab systems for vaccine processing and testing, thermal imaging to control the body temperature in highly frequented places, and multiple camera-based inspection systems for pharmaceuticals and medical goods. Robotic vision systems, including 2D and 3D machine vision systems, provide greater flexibility, enabling manufacturers to produce a wide range of components more cost-effectively. Furthermore, there has been a continuous rise in the demand for automation for metrological processes such as quality inspection due to the increasing number of smart factories.

Several leading robotic vision players took this global crisis as a new opportunity to restructure and revisit their existing strategies and develop an advanced product portfolio. For instance,

Such initiatives by major market players and the increasing demand for vision technology in consumer electronics applications are expected to support the growth of the robotic vision market in the coming years.

Click here to: Get Free Sample Copy of this report

The Advent of Industry 4.0 Expected To Drive Market Growth

Industry 4.0 is a trend of automation and data exchange in industrial manufacturing. The demand for automation has increased in industrial manufacturing due to the proliferation of advanced technologies, including the Internet of Things (IoT), AI, and cloud computing. Robotic vision is an essential element of automation and critical to Industry 4.0. Imaging technologies such as 3D machine vision systems rely on low-latency and uncompressed data to make real-time decisions. Poor data quality or delivery can translate into costly production halts, secondary inspections, or a product recall that can harm the company's reputation. Integrating advanced technologies into robotic vision systems helps integrate numerous image and data sources, including output from 2D, 3D, and 4D sensors. IoT helps robotic vision pave the path toward integrating artificial intelligence (AI) and machine learning into inspection systems. The application of machine vision in IoT involves delivering a level of interpretation and abstraction used in decision-making or further automation. Additionally, it helps to expand robots' role in performing production-line tasks, including picking, sorting, and performing a manufacturing line scan. Furthermore, sensors are becoming increasingly intelligent and supporting computer vision algorithms; hence, the data produced offers valuable insights into industrial systems' operation, which helps manufacturers in decision-making for their business strategies.

Implementation of cloud computing in robot vision technologies helps manage the data output from the machine vision sensors better. 3D machine vision systems are responsible for acquiring and processing image data for industrial applications. In the absence of cloud technology, 3D machine vision systems are limited in the amount of data that can be processed. Thus, cloud computing helps machine vision technologies to reach their full commercial potential. Thus, the advent of Industry 4.0 has led to an increase in smart factories, subsequently driving the adoption of technologies, such as IoT, AI, and cloud computing, for automating manufacturing processes.

Key Findings in the Robotic Vision Market Study:

In 2022, the Hardware Segment is Expected to Dominate the Robotic Vision Market

Based on offering, the robotic vision market is segmented into hardware and software. In terms of value, in 2022, the hardware segment is expected to account for the larger share of the robotic vision market. The large market share of this segment is mainly attributed to the growing demand for complementary metal-oxide-semiconductor (CMOS) imaging sensors, the increasing adoption of robots to automate repetitive processes, the increasing use of cognitive humanoid robots, and the rising deployment of machine vision systems.

In 2022, the 3D Vision Systems Segment is Expected to Dominate the Robotic Vision Market

Based on type, the robotic vision market is segmented into 2D vision systems, 3D vision systems, and 4D vision systems. In terms of value, in 2022, the 3D vision systems segment is expected to account for the largest share of the robotic vision market. The large market share of this segment is mainly attributed to the increasing demand for vision-guided robotic systems from the automotive, food & beverage, pharmaceutical & chemical, and packaging sectors and the rising demand for quality inspection and automation.

Asia-Pacific to be the Fastest-growing Regional Market

Based on geography, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is projected to register the highest CAGR during the forecast period. The growth of this regional market is driven by the increasing deployment of machine vision systems for scanning and inspecting the quality of objects in the industrial sector and the growing demand for enhanced inspection systems to enable high-quality and zero-defect products. Furthermore, factors such as the rising government initiatives in countries such as India, Singapore, and South Korea for attracting FDI in the manufacturing sector contribute to the market’s growth in Asia-Pacific.

Key Players

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by the leading market participants between last two years. The key players profiled in the robotic vision market report include FANUC Corporation (Japan), Qualcomm Technologies, Inc. (U.S.), Hexagon AB (Sweden), ABB Group (Switzerland), Teledyne Dalsa Inc. (Canada), Cognex Corporation (U.S.), Basler AG (Germany), OMRON Corporation (Japan), National Instruments Corporation (U.S.), Keyence Corporation (Japan), Sick AG (Germany), Tordivel AS (Norway), Advantech (Taiwan), ISRA Vision (Germany), Yaskawa America, Inc. (Japan), Cadence Design Systems, Inc. (U.S.), Panasonic Holdings Corporation (U.S.), Allied Vision Technologies GmbH (Germany), MVTec Software GmbH (Germany), Xenics NV (Belgium), Industrial Vision Systems Ltd (U.K.), and Apera AI (Canada).

Scope of the Report:

Robotic Vision Market, by Offering

Robotic Vision Market, by Type

Robotic Vision Market, by Application

Robotic Vision Market, by End User

Robotic Vision Market, by Geography

Key questions answered in the report:

The robotic vision market is projected to reach $5.2 billion by 2029 at a CAGR of 11% during the forecast period.

The growth of this market is attributed to the high adoption of 3D vision systems in industrial robotics, the advent of industry 4.0, and the rising demand for automated quality inspection technologies. In addition, increasing government initiatives to support industrial automation and the growing deployment of machine vision systems across various end-use industries are expected to offer significant opportunities for the growth of this market.

The key players operating in the robotic vision market include FANUC Corporation (Japan), Qualcomm Technologies, Inc. (U.S.), Hexagon AB (Sweden), ABB Group (Switzerland), Teledyne Dalsa Inc. (Canada), Cognex Corporation (U.S.), Basler AG (Germany), OMRON Corporation (Japan), National Instruments Corporation (U.S.), Keyence Corporation (Japan), Sick AG (Germany), Tordivel AS (Norway), Advantech (Taiwan), ISRA Vision (Germany), Yaskawa America, Inc. (Japan), Cadence Design Systems, Inc. (U.S.), Panasonic Holdings Corporation (U.S.), Allied Vision Technologies GmbH (Germany), MVTec Software GmbH (Germany), Xenics NV (Belgium), Industrial Vision Systems Ltd (U.K.), and Apera AI (Canada).

Published Date: May-2025

Published Date: Feb-2025

Published Date: Nov-2024

Published Date: Jun-2024

Published Date: Sep-2022

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates