Resources

About Us

Predictive Maintenance Market by Offering (Software, Hardware), Deployment Mode, Organization Size, Technology (IoT, AI & ML), Application (Oil Analysis, Temperature Monitoring), End-use Industry, and Geography - Global Forecast to 2032

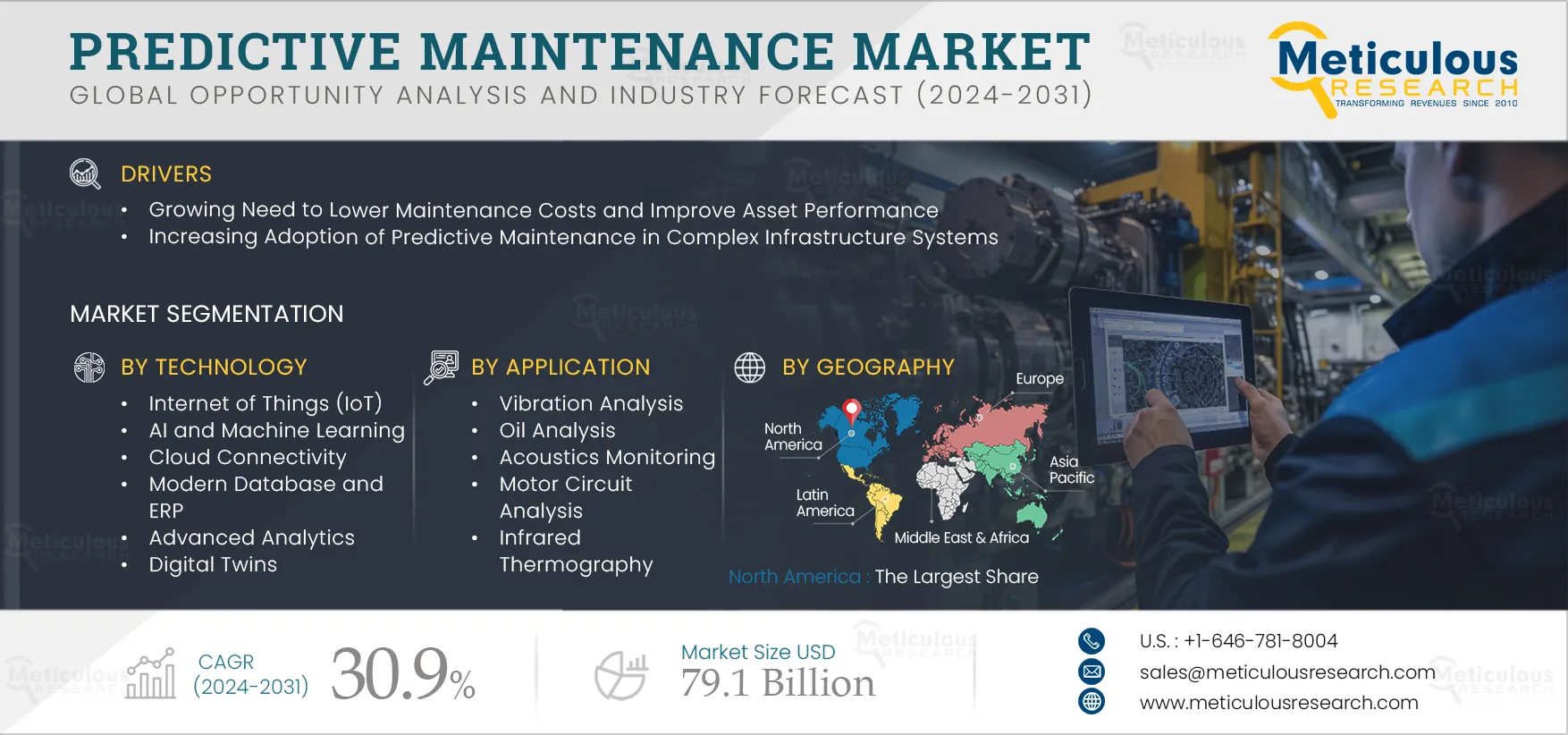

Report ID: MRICT - 1041253 Pages: 300 Jun-2024 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportThe Predictive Maintenance Market is projected to reach $79.1 Billion by 2032, at a CAGR of 30.9% from 2025 to 2032. The growth of the predictive maintenance market is driven by the growing need to lower maintenance costs and improve asset performance and the increasing adoption of predictive maintenance in complex infrastructure systems. Furthermore, the expansion of predictive maintenance solutions in healthcare devices and navigation systems is expected to generate growth opportunities for the players operating in this market.

Predictive maintenance is growingly used in industries to lower maintenance costs and to improve asset performance. There are several technologies used in predictive maintenance, such as data analytics and machine learning, condition monitoring, and performance optimizations. Using these technologies organizations are effectively lower maintenance costs, enhance asset reliability, and achieve operational efficiency through predictive maintenance practices. Moreover, predictive maintenance helps to reduce unplanned downtime and associated costs by addressing maintenance needs and optimizes spare parts inventory and procurement through predictive maintenance forecasting.

Additionally, with the increasing use of advanced technologies and the growing adoption of Industry 4.0, several companies are launching predictive maintenance solutions for organizations. For instanc, in October 2021, ABB Ltd (Switzerland) launched ABB Ability Genix, an asset performance management suite that brings next-generation AI-based predictive maintenance, asset reliability, and integrity insights to process and utility industries. Genix APM is an enterprise-grade application to monitor assets, prescribe maintenance actions, improve equipment utilization, and support lifecycle analysis and capital planning. Such growing developments help to increase the demand for predictive maintenance to lower the cost of maintenance and improve asset performance during the forecast period.

Click here to: Get Free Sample Pages of this Report

Click here to: Get Free Sample Pages of this Report

The complex infrastructure systems comprise diverse equipment and components in predictive maintenance solutions that help to maintain this equipment on a regular basis. The predictive maintenance of IoT sensors and data collection mechanisms across these systems create a comprehensive dataset. Predictive maintenance helps to apply analytical techniques such as machine learning algorithms to analyze large volumes of data effectively. Additionally, it helps to develop predictive models that anticipate equipment failures or performance degradation based on historical patterns and real-time data. Predictive maintenance utilizes real-time monitoring technologies to continuously assess the condition of critical infrastructure components.

Additionally, the growing adoption of predictive maintenance solutions for risk assessment and mitigations to identify potential failure modes and prioritize assets based on criticality. The integration of predictive maintenance practices with asset management systems to streamline workflows and improve resource allocation. These solutions help to ensure seamless communication between predictive maintenance tools and other operational systems for coordinated maintenance activities. Thus, by addressing these factors, organizations can successfully increase the adoption of predictive maintenance in complex infrastructure systems.

The integration of digital twins and augmented reality (AR) plays a crucial role in enhancing predictive maintenance in complex infrastructure systems. The integration of AR in predictive maintenance helps to simulate maintenance procedures in a safe virtual environment, allowing technicians to practice and familiarize themselves with tasks before performing them on actual equipment. Additionally, the integration of AR helps visualize data from digital twins in a user-friendly manner that allows maintenance teams to quickly interpret complex information and make informed decisions. Thus, the growing integration of AR helps to reduce unplanned downtime, optimize spare parts inventory, and extend the lifespan of critical infrastructure assets.

Moreover, digital twins are virtual representations of physical assets or systems. They simulate real-world conditions and behaviors that allow predictive analysis and scenario testing without impacting actual operations. Digital twins gather data from sensors embedded in physical assets. This real-time data is crucial for predictive maintenance, as it provides insights into current conditions and performance metrics. With the growing integration of AR and digital twins, several companies are partnering to launch predictive maintenance solutions using digital twins. For instance, in March 2024, Modelon, Inc. (Sweden) partnered with Iquant LLC (U.S.) to deliver digital twin solutions for predictive maintenance of power plants and energy infrastructure. Modelon’s technology accurately models physical systems, allowing for the analysis of a real asset, including fluid dynamic behavior, heat transfer, and mechanical dynamics. Such growing developments help to increase the demand for digital twins and AR for predictive maintenance.

Based on offering, the predictive maintenance market is segmented into software, hardware, and services. In 2025, the software segment is expected to account for the largest share of above 81.0% of the predictive maintenance market. The segment's large market share is attributed to the growing need to lower maintenance costs, the growing adoption of predictive maintenance software to ensure compliance by providing documentation of maintenance activities and adherence to maintenance schedules; and the increasing use of predictive maintenance to provide valuable insights into equipment performance, trends, and patterns for decision making and optimization of maintenance strategies.

However, the services segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the adoption of predictive maintenance services to analyze equipment data and identify potential issues, and the growing need to lower overall maintenance costs. Predictive maintenance services help to create a safer work environment for employees by reducing the risk of unexpected equipment failures and the growing integration of IoT, AI, and Ml in predictive maintenance to provide real-time monitoring of equipment performance, contributing to the segment's high growth.

Based on deployment mode, the predictive maintenance market is segmented into cloud-based deployments and on-premise deployments. In 2025, the cloud-based deployments segment is expected to account for the larger share of above 58.0% of the predictive maintenance market. The segment's large market share is attributed to the growing adoption of cloud-based solutions to scale up or down based on the needs of the business; the increasing use of cloud-based predictive maintenance to analyze large volumes of data in real-time and leverages the scalability of cloud computing resources; and cloud-based platforms offering advanced analytics capabilities, including machine learning and predictive modeling.

Also, this segment is expected to register the highest CAGR during the forecast period.

Based on organization size, the predictive maintenance market is segmented into large enterprises and small & medium-sized enterprises. In 2025, the large enterprises segment is expected to account for the larger share of above 74.0% of the predictive maintenance market. The segment's large market share is attributed to the growing adoption of predictive maintenance to avoid costly unplanned downtime and repairs. Predictive maintenance is used in large enterprises to monitor equipment health in real time, identify performance degradation, and take proactive measures to maintain optimal operating conditions.

However, the small & medium-sized enterprises segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the growing adoption of predictive maintenance to reduce the burden on maintenance staff by automating the monitoring and analysis of equipment health. Predictive maintenance helps SMEs to meet regulatory requirements by ensuring that equipment is properly maintained and operating within prescribed limits, and the rising use of predictive maintenance in SMEs to enhance their operational efficiency, mitigate risks, and position themselves for long-term sustainability.

Based on technology, the predictive maintenance market is segmented into internet of things (IoT), AI and machine learning, cloud connectivity, modern database and ERP, advanced analytics, and digital twins. In 2025, the IoT segment is expected to account for the largest share of the predictive maintenance market. The segment's large market share is attributed to the growing use of IoT-based predictive maintenance to predict equipment failures and improve technician efficiency by providing real-time information about equipment performance.

However, the AI and machine learning segment is expected to register the highest CAGR during the forecast period. This segment's growth is attributed to the growing adoption of AI and ML in predictive maintenance for real-time analytics. AI-based predictive maintenance contributes to energy savings and reduces the environmental footprint of industrial operations. AI and ML algorithms analyze large volumes of data from sensors, equipment logs, and other sources to identify patterns and trends, also contributing to the segment’s high growth.

Based on application, the predictive maintenance market is segmented into vibration analysis, oil analysis, acoustics monitoring, motor circuit analysis, infrared thermography, temperature monitoring, and other applications. In 2025, the temperature monitoring segment is expected to account for the largest share of above 26.0% of the predictive maintenance market. The segment's large market share is attributed to the growing adoption of predictive maintenance for equipment failures or malfunctions for early intervention, energy savings, reduced operating costs of equipment, and the rising use of predictive maintenance to provide notification to maintenance personnel for investigation and preventive action.

However, the vibration analysis segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the growing adoption of predictive maintenance for vibration analysis to detect, measure, and analyze vibration in rotating parts of machinery and the rising use of predictive maintenance to control downtime and maintenance processes and enhance product quality with machinery running at rated tolerances more consistently.

Based on end-use industry, the predictive maintenance market is segmented into manufacturing, energy & utilities, automotive & transportation, aerospace & defense, oil & gas, healthcare, construction & mining, IT & telecom, and other end-use industries. In 2025, the manufacturing segment is expected to account for the largest share of above 30.0% of the predictive maintenance market. The segment's large market share is attributed to the growing adoption of predictive maintenance to avoid costs associated with unscheduled downtime and the increasing adoption of Industry 4.0 for manufacturing to increase production efficiency and reduce costs.

However, the healthcare segment is expected to register the highest CAGR during the forecast period. This segment's growth is attributed to the growing use of IoT and telematics in healthcare facilities and the increasing use of predictive maintenance to collect data on parameters such as temperature, pressure, and electrical current of medical equipment.

In 2025, North America is expected to account for the largest share of above 33.0% of the predictive maintenance market. North America’s significant market share can be attributed to the increasing demand for predictive maintenance in the healthcare sector, the growing demand to reduce equipment failure, maintenance costs, and downtime, the rising adoption of advanced technology such as IoT, AI, and ML; and the increasing the number of industries in North America to meet demand and supply.

However, the Asia-Pacific market is expected to register the highest CAGR of above 32.0% during the forecast period. This region's growth is attributed to the growing expansion of small & medium-sized industries, the growing industrialization coupled with increasing government initiatives, the growing need to lower maintenance costs and improve asset performance, and the emergence of industry 4.0 in the manufacturing landscape in various countries such as China, India, and Japan.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–to 4 years. Some of the key players operating in the predictive maintenance market are International Business Machines Corporation (U.S.), ABB Ltd (Switzerland), Hitachi, Ltd. (Japan), Siemens AG (Germany), Amazon Web Services, Inc. (A Subsidiary of Amazon.com, Inc.) (U.S.), Google LLC (A Subsidiary of Alphabet Inc.) (U.S.), Microsoft Corporation (U.S.), Emerson Electric Co. (U.S.), Oracle Corporation (U.S.), Splunk Inc. (A Subsidiary of Cisco Systems, Inc.) (U.S.), Axiomtek Co., Ltd. (Taiwan), Presage Insights pvt ltd (India), XMPro Inc. (U.S.), Faclon Labs Private Limited (India), and SenseGrow Inc. (U.S.).

In July 2022, CemAI, Inc. (U.S.) launched artificial intelligence (AI) solutions for cement plants with a predictive maintenance solution that combines proprietary licensed software with a continuous monitoring and incident resolution service for cement manufacturing lines.

In January 2022, Bigfinite Inc. (Aizon) (U.S.) launched its new asset monitoring application for pharmaceutical manufacturers and biotech companies. Aizon’s GxP-compliant AI SaaS Platform, Aizon Asset Health, provides intelligent historical maintenance analysis, proactively monitors the condition of critical assets in real time, and identifies potential problems.

|

Particulars |

Details |

|

Number of Pages |

300 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

30.9% |

|

Market Size (Value) |

USD 79.1 Billion by 2032 |

|

Segments Covered |

By Offering

By Deployment Mode

By Organization Size

By Technology

By Application

By End-use Industry

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Netherlands, Spain, Sweden, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (Saudi Arabia, UAE, Israel, and Rest of the Middle East & Africa) |

|

Key Companies |

International Business Machines Corporation (U.S.), ABB Ltd (Switzerland), Hitachi, Ltd. (Japan), Siemens AG (Germany), Amazon Web Services, Inc. (A Subsidiary of Amazon.com, Inc.) (U.S.), Google LLC (A Subsidiary of Alphabet Inc.) (U.S.), Microsoft Corporation (U.S.), Emerson Electric Co. (U.S.), Oracle Corporation (U.S.), Splunk Inc. (A Subsidiary of Cisco Systems, Inc.) (U.S.), Axiomtek Co., Ltd. (Taiwan), Presage Insights pvt ltd (India), XMPro Inc. (U.S.), Faclon Labs Private Limited (India), and SenseGrow Inc. (U.S.). |

The predictive maintenance market study focuses on market assessment and opportunity analysis through the sales of predictive maintenance offerings across different regions and market segmentations. This study is also focused on competitive analysis for predictive maintenance based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies.

The predictive maintenance market is projected to reach $79.1 billion by 2032, at a CAGR of 30.9% from 2025 to 2032.

In 2025, the IoT segment is expected to account for the largest share of the predictive maintenance market. The segment's large market share is attributed to the growing use of IoT-based predictive maintenance to predict equipment failures and improve technician efficiency by providing real-time information about equipment performance.

The vibration analysis segment is expected to register the highest CAGR during the forecast period. This segment's growth is attributed to the growing adoption of predictive maintenance for vibration analysis to detect, measure, and analyze vibration in rotating parts of machinery; the rising use of predictive maintenance to control downtime and maintenance processes and enhance product quality with machinery running at rated tolerances more consistently.

The growth of the predictive maintenance market is driven by the growing need to lower maintenance costs and improve asset performance and the increasing adoption of predictive maintenance in complex infrastructure systems. Furthermore, the expansion of predictive maintenance solutions in healthcare devices and navigation systems is expected to generate growth opportunities for the players operating in this market.

The key players operating in the predictive maintenance market International Business Machines Corporation (U.S.), ABB Ltd (Switzerland), Hitachi, Ltd. (Japan), Siemens AG (Germany), Amazon Web Services, Inc. (A Subsidiary of Amazon.com, Inc.) (U.S.), Google LLC (A Subsidiary of Alphabet Inc.) (U.S.), Microsoft Corporation (U.S.), Emerson Electric Co. (U.S.), Oracle Corporation (U.S.), Splunk Inc. (A Subsidiary of Cisco Systems, Inc.) (U.S.), Axiomtek Co., Ltd. (Taiwan), Presage Insights pvt ltd (India), XMPro Inc. (U.S.), Faclon Labs Private Limited (India), and SenseGrow Inc. (U.S.).

The Asia-Pacific region is expected to register the highest CAGR of above 32.0% during the forecast period. This market's growth is attributed to the growing expansion of small & medium-sized industries, the growing industrialization coupled with increasing government initiatives, the growing need to lower maintenance costs and improve asset performance, and the rising emergence of Industry 4.0 in the manufacturing landscape in various countries such as China, India, and Japan.

Published Date: Sep-2024

Published Date: Jun-2019

Published Date: May-2024

Published Date: Jan-2025

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates