Resources

About Us

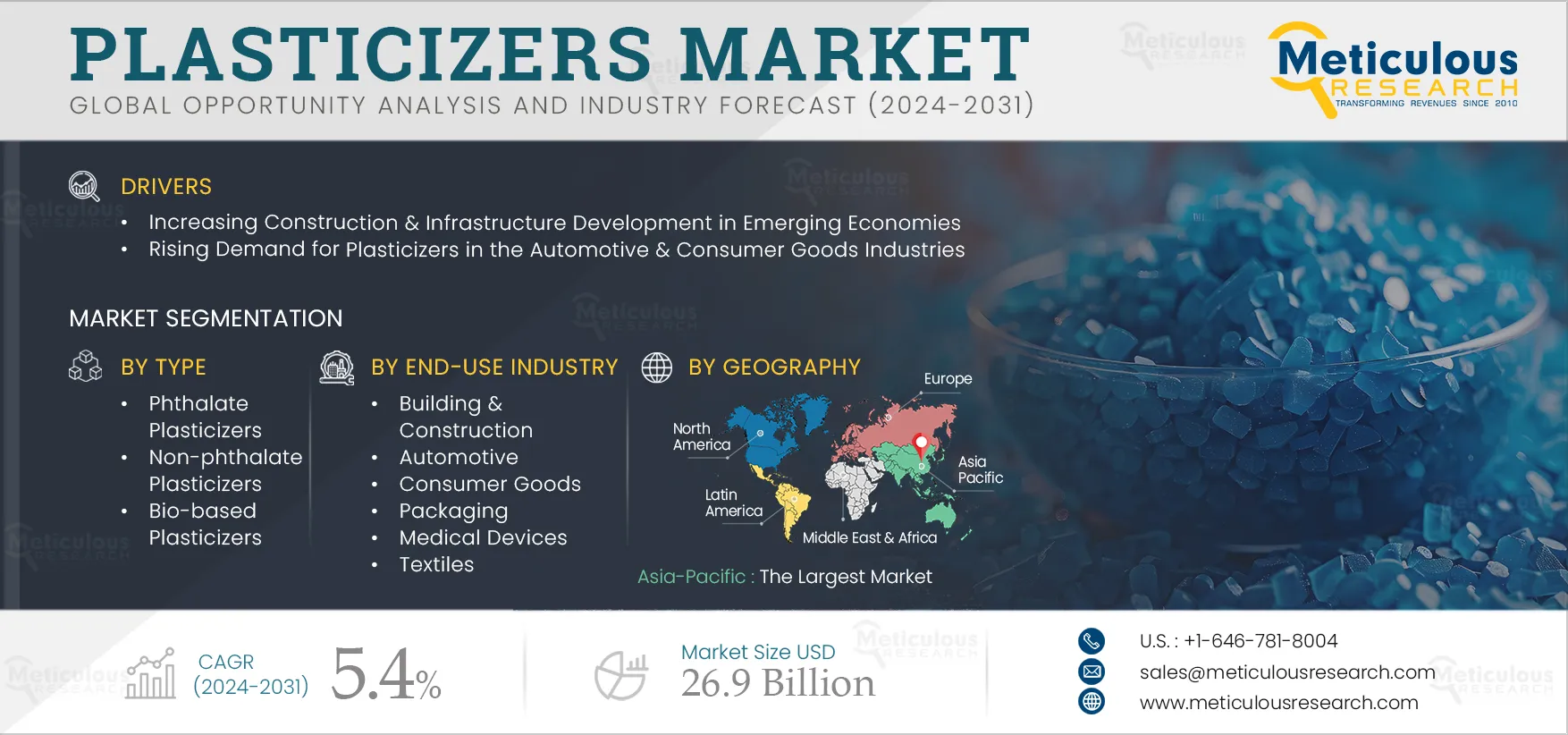

Plasticizers Market Size, Share, Forecast, & Trends Analysis by Type (Phthalate, Non-phthalate, Bio), End-use Industry (Building & Construction {Wires & Cables, Flooring & Wall Coverings, Roofing Membranes}, Automotive, Packaging) - Global Forecast to 2032

Report ID: MRCHM - 1041339 Pages: 240 Oct-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of the plasticizers market is primarily driven by the increasing construction & infrastructure development in emerging economies and the rising demand for plasticizers in the automotive & consumer goods industries. However, volatile raw material prices restrain the growth of this market.

Additionally, the growing demand for eco-friendly plasticizers and the increasing utilization of plasticizers in the manufacture of packaging materials are expected to create growth opportunities for the players operating in the market. However, stringent government regulations pertaining to plastic products are a major challenge impacting market growth.

Click here to: Get Free Sample Pages of this Report

Rapid urbanization and industrialization are driving an increase in construction & infrastructure development projects in emerging economies, particularly in Asia-Pacific, Latin America, and the Middle East & Africa. Construction and infrastructure development refer to the building and expansion of physical structures and facilities, including residential and commercial buildings, bridges, highways, roads, mass transit facilities, airports, and utilities. Plasticizers are used in the construction and infrastructure sectors to enhance the flexibility, durability, and workability of materials, including concrete, asphalt, and PVC. They are used in applications such as wires & cables, flooring & wall coverings, roofing membranes, and piping systems.

Major players in this market are focusing on the development of bio-sourced admixture solutions to enhance the strength and workability of concrete and contribute to sustainability by reducing the carbon footprint of construction materials. For instance, in January 2024, Cemex, S.A.B. de C.V. (Mexico) launched a range of next-generation bio-sourced admixture solutions that utilize a natural, renewable, and locally sourced raw material to deliver a lower carbon footprint. These admixtures are added to concrete mixes to enhance attributes, including strength, workability, and water demand, which reduces the carbon footprint and promotes more sustainable practices in construction. Such developments, along with the growing demand for high-performance and cost-effective construction materials, increasing government investments in infrastructure, and the increasing use of plasticizers in construction materials to achieve the desired performance characteristics, are driving the growth of the plasticizers market.

Companies in the automotive and consumer goods industries face several challenges related to product durability and performance, including the products’ ability to withstand extreme temperatures, vibrations, and wear, and product compliance with stringent government regulations. Hence, companies are using plasticizers to address these challenges. Automotive manufacturers use plasticizers to enhance the flexibility of materials, including PVC, to increase the durability of interior & exterior parts and wire & cable insulation, increase the adhesion & elasticity of sealers, prevent brittleness, and ensure reliable product performance under varying temperatures. In the consumer goods sector, plasticizers are used in applications, including footwear, sports equipment, toys, and childcare products, to improve the softness and flexibility of materials.

Major players in this market are focused on enhancing the performance and durability of their plasticizer products to ensure low volatility & high temperature resistance, meet the growing demand for advanced plasticizers, and support innovation in the automotive and consumer goods industries. For instance, in November 2022, Evonik Industries AG (Germany) signed a memorandum of understanding with DEZA, a.s. (Czech) for the production of the plasticizer tri-isononyl trimellitate (TINTM). TINTM is marketed under the brand name ELATUR® TM and is characterized by a particularly high temperature resistance, low volatility, and low migration behavior. It is suitable for applications including high-temperature cables and automotive interiors. Such developments, along with advances in the automotive sector, such as the increasing incorporation of lightweight and high-performance materials and rising consumer expectations in terms of product quality & performance, are boosting the adoption of plasticizers, driving the growth of this market.

With the increasing focus on sustainability, companies across industries are facing significant challenges related to environmental protection and regulatory compliance. Plasticizers can have adverse health & long-term ecological impacts if they leach into the environment. These concerns have resulted in stricter regulations and accelerated the enforcement of more sustainable practices. Eco-friendly plasticizers help address environmental and health concerns by offering similar performance characteristics while being more sustainable. Eco-friendly plasticizers are derived from renewable resources and are designed to be less harmful to both human health and the environment. Bio-based plasticizers include eco-friendly options such as citrate esters, Epoxidized Soybean Oil (ESBO), glycerol esters, and succinates. They are used in building and construction materials, automotive components, consumer goods, and medical devices to enhance product performance while ensuring compliance with environmental standards.

Major players in this market are focusing on eco-friendly plasticizers as they are a sustainable alternative to traditional fossil-based plasticizers, minimize environmental impacts, and support greener manufacturing practices. In February 2025, Perstorp AB (Sweden) launched a renewable carbon-based non-phthalate plasticizer called Pevalen™ Pro 100. The new grade of Pevalen features 100% renewable carbon content based on mass balance. It offers a product carbon footprint reduction of approximately 80.0% relative to its fossil-based equivalent from cradle to Perstorp gate. This reduction is achieved by considering the biogenic CO2 uptake from its renewable raw materials. Such developments, along with the increasingly stringent environmental regulations and rising consumer awareness about sustainability, are expected to generate growth opportunities for market players focused on introducing eco-friendly, bio-based offerings.

Packaging helps maintain product quality, extends product shelf life, and ensures consumer safety. Packaging ensures that products remain intact throughout the logistics chain from manufacturer to the end user. It protects products from humidity, light, heat, and other external factors. Packaging materials are used to enclose or hold together packaged goods during storage, handling, and transportation. Plasticizers are used in the manufacturing of packaging materials to enhance their flexibility, durability, and performance. They improve the strength, flexibility, and stretchability of films and enhance sealability, softness, durability, and adhesion, resulting in more effective and efficient packaging solutions.

The increasing demand for advanced packaging solutions in the food processing & pharmaceutical sectors, the growing focus on sustainable packaging, advancements in packaging technologies, and the rapid growth of the e-commerce sector are driving the demand for advanced packaging solutions. According to the Census Bureau of the Department of Commerce (U.S.), the total e-commerce sales for 2024 were estimated at $1,118.7 billion, an increase of 7.6% compared to 2022. According to the India Brand Equity Foundation (India), the Indian online grocery market is estimated to reach $26.93 billion in 2027 from $3.95 billion in 2021, expanding at a CAGR of 33%. Also, the Indian e-commerce industry is projected to reach $300 billion by 2032, witnessing significant growth. Hence, as more consumers shift toward online shopping, companies are investing in advanced packaging solutions to meet higher sales volumes and streamline operations. This shift has increased the demand for plasticizers in the manufacture of packaging materials, generating growth opportunities for market stakeholders.

Based on type, the plasticizers market is broadly segmented into phthalate plasticizers, non-phthalate plasticizers, and bio-based plasticizers. Phthalate plasticizers are further segmented into Diethylhexyl Phthalate (DEHP), Diisononyl Phthalate (DINP), Diisodecyl Phthalate (DIDP), Butyl Benzyl Phthalate (BBP), Dioctyl Phthalate (DOP), and other phthalate plasticizers. Non-phthalate plasticizers are further segmented into adipates, benzoates, trimellitates, epoxies, phosphate esters, and other non-phthalate plasticizers. Bio-based plasticizers are further segmented into citrate esters, Epoxidized Soybean Oil (ESBO), glycerol esters, and other bio-based plasticizers. In 2025, the phthalate plasticizers segment is expected to account for the largest share of over 47% of the plasticizers market. The segment’s large market share can be attributed to phthalate plasticizers’ effectiveness in improving the flexibility, durability, and workability of plastics and the growing use of phthalate plasticizers in products such as vinyl flooring, pipes, wiring insulation, and coatings.

However, the bio-based plasticizers segment is projected to witness the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by increasing regulatory pressures and environmental awareness, the growing consumer preference for eco-friendly and sustainable products, and the increasing use of bio-based plasticizers in food & beverage packaging materials and medical tubing, among other applications.

Based on end-use industry, the plasticizers market is broadly segmented into building & construction, automotive, consumer goods, packaging, medical devices, textiles, and other end-use industries. The building & construction segment is subsegmented into wires & cables, flooring & wall coverings, roofing membranes, and other building & construction applications. The automotive segment is subsegmented into interior & exterior parts, automotive sealers & adhesives, wire & cable insulation, and other automotive applications. The consumer goods segment is subsegmented into footwear, sports & leisure products, toys & childcare products, and other consumer goods applications. The packaging segment is subsegmented into flexible packaging, rigid packaging, and other packaging applications. The medical devices segment is subsegmented into tubes & bags, IV containers, and other medical device applications. The textile segment is subsegmented into coated fabrics, synthetic leather, and other textile applications. In 2025, the building & construction segment is expected to account for the largest share of over 35% of the plasticizers market. The segment’s large market share can be attributed to rapid urbanization & infrastructure development, and the growing use of plasticizers in the production of vinyl flooring, pipes & tubing, wall coverings, and sealants & adhesives to enhance the flexibility, durability, and workability of these construction materials.

However, the medical devices segment is projected to witness the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by the increasing demand for plasticizers due to advancements in healthcare, increasing medical needs, the shift toward non-toxic & biocompatible materials, and the growing use of plasticizers in the manufacture of diagnostic tools & equipment, medical tubing, implants, and disposable medical products including gloves, syringes, and blood bags to improve their functionality and ensure safe and reliable performance.

Based on geography, the plasticizers market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of over 53% of the plasticizers market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific's large market share can be attributed to the ongoing industrialization in countries such as China, South Korea, and India, the increasing use of plasticizers to enhance the performance and flexibility of products across various industries, growing construction activities across APAC countries, the rapid expansion of the automotive industry, the increasing demand for advanced packaging solutions in the food processing sector, and the growing demand for consumer goods such as electronics and toys in the region.

Moreover, Asia-Pacific is also slated to register the highest growth rate of over 6.5% during the forecast period. The growth of this regional market is driven by the growing consumer preference for products with enhanced durability, flexibility, and safety and increasing product safety and environmental regulations and standards driving the use of eco-friendly products, such as non-phthalate and bio-based plasticizers.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. The key players operating in the plasticizers market include UPC Technology Corporation (Taiwan), Exxon Mobil Corporation (U.S.), BASF SE (Germany), Evonik Industries AG (Germany), Eastman Chemical Company (U.S.), Aekyung Chemical (South Korea), LG Chem, Ltd. (South Korea), DIC Corporation (Japan), Kao Corporation (Japan), Avient Corporation (U.S.), Polynt S.p.A. (Italy), KLJ Group (India), Arkema Group (France), Perstorp AB (Sweden), The Dow Chemical Company (U.S.), and Nan Ya Plastics Corporation (Taiwan).

|

Particulars |

Details |

|

Number of Pages |

240 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

5.4% |

|

Market Size (Value) |

$26.9 Billion by 2032 |

|

Segments Covered |

By Type

By End-use Industry

|

|

Countries Covered |

Europe (Germany, U.K., Italy, France, Spain, Russia, Netherlands, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Thailand, Singapore, and Rest of Asia-Pacific), North America (U.S. and Canada), Latin America (Brazil, Argentina, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, South Africa, and Rest of Middle East & Africa) |

|

Key Companies Profiled |

UPC Technology Corporation (Taiwan), Exxon Mobil Corporation (U.S.), BASF SE (Germany), Perstorp AB (Sweden), Evonik Industries AG (Germany), Eastman Chemical Company (U.S.), Aekyung Chemical (South Korea), LG Chem, Ltd. (South Korea), DIC Corporation (Japan), Kao Corporation (Japan), Avient Corporation (U.S.), Polynt S.p.A. (Italy), KLJ Group (India), Arkema Group (France), The Dow Chemical Company (U.S.), and Nan Ya Plastics Corporation (Taiwan) |

The plasticizers market study focuses on market assessment and opportunity analysis based on the sales of plasticizers across various regions, countries, and market segments. This study also includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last three to four years.

The plasticizers market is projected to reach $26.9 billion by 2032, at a CAGR of 5.4% during the forecast period.

Based on type, the plasticizers market is broadly segmented into phthalate plasticizers, non-phthalate plasticizers, and bio-based plasticizers. In 2025, the phthalate plasticizers segment is expected to account for the largest share of over 47.0% of the plasticizers market. The large market share of this segment can be attributed to phthalate plasticizers’ effectiveness in improving the flexibility, durability, and workability of plastics and the growing use of phthalate plasticizers in the production of vinyl flooring, pipes, wiring insulation, and coatings, among other products.

The medical devices segment is projected to witness the highest growth during the forecast period 2025–2032, mainly driven by the increasing demand for plasticizers due to advancements in healthcare, increasing medical needs, the shift toward non-toxic & biocompatible materials, and the growing use of plasticizers in the production of diagnostic tools & equipment, medical tubing, implants, and disposable medical products including gloves, syringes, and blood bags to improve their functionality and ensure safe and reliable performance.

The growth of this market is driven by increasing construction & infrastructure development in emerging economies and the rising demand for plasticizers in the automotive & consumer goods industries. Additionally, the growing demand for eco-friendly plasticizers and the increasing utilization of plasticizers in the manufacture of packaging materials are expected to create market growth opportunities.

The key players operating in the plasticizers market are UPC Technology Corporation (Taiwan), Exxon Mobil Corporation (U.S.), BASF SE (Germany), Evonik Industries AG (Germany), Eastman Chemical Company (U.S.), Aekyung Chemical (South Korea), LG Chem, Ltd. (South Korea), DIC Corporation (Japan), Kao Corporation (Japan), Avient Corporation (U.S.), Polynt S.p.A. (Italy), KLJ Group (India), Perstorp AB (Sweden), Arkema Group (France), The Dow Chemical Company (U.S.), and Nan Ya Plastics Corporation (Taiwan).

Asia-Pacific is expected to offer significant growth opportunities for the vendors in the plasticizers market during the analysis period as the region is witnessing rapid industrialization & urbanization, with an increasing demand for plasticizers in various applications, including construction, automotive, and consumer goods.

Published Date: May-2024

Published Date: Oct-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates