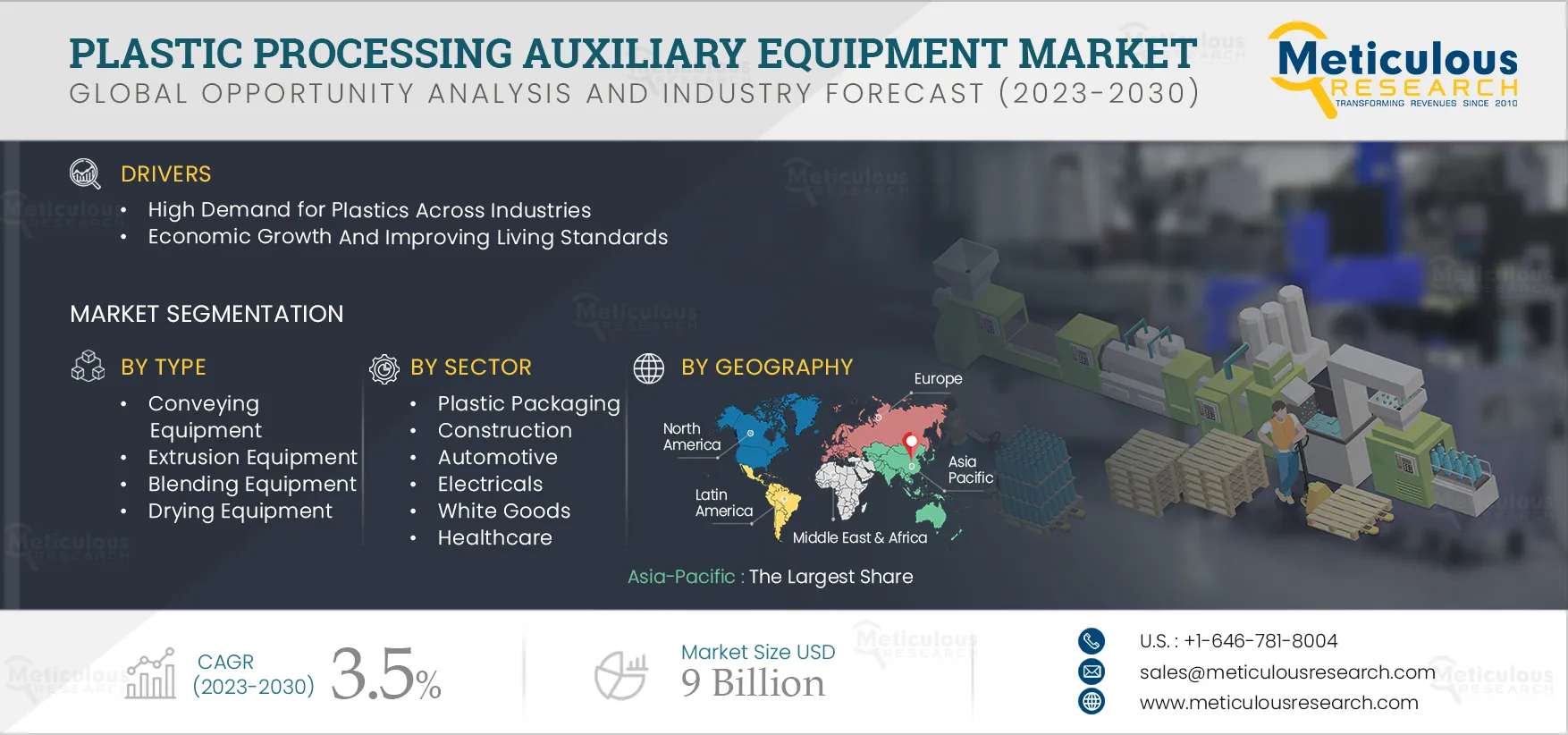

The Plastic Processing Auxiliary Equipment Market is projected to reach USD 9 billion by 2030, at a CAGR of 3.5% from 2023 to 2030. The growth of this market is driven by the high demand for plastics across industries and improving living standards. However, the rising awareness regarding plastic pollution and the growing emphasis on reusing plastics restrain the growth of this market.

The proliferation of advanced plastic recycling techniques is expected to create growth opportunities for the players operating in this market. However, government initiatives to ban single-use plastics are a major challenge to market growth. Additionally, growing consumer awareness regarding sustainability and the adoption of advanced technologies in plastic processing are prominent trends in the plastic processing auxiliary equipment market.

Here are the top 10 companies operating in the Plastic Processing Auxiliary Equipment Market

Founded in 1860 and headquartered in Ohio, U.S., Milacron is engaged in the manufacturing and distribution of plastic-processing equipment and machinery. The company’s product portfolio comprises equipment such as injection molding, blow molding, extrusion and auxiliary systems.

Milacron offers its products across various industries, including consumer goods, packaging, electronics, medical, automotive, and construction end markets in North America, Europe, China, and India through its subsidiaries and strong distribution network.

Piovan Group

Founded in 1934 and headquartered in Venice, Italy, Piovan Group is a leading player in the development and production of automation systems for the storage, conveyance and processing of plastic. The company is engaged in the designing and manufacturing of auxiliary equipment for the plastic processing industry.

The company operates in the market through three business segments, namely, Plastic, Food & Non Plastic, and Services. It offers auxiliary equipment, such as feeding and conveying units, drying and dehumidifying units, dosing and blending systems, and granulation systems. Conair, a part of Piovan Group, is the leading supplier of auxiliary equipment, solutions and installed systems for plastic processing plants.

Founded in 1875 and headquartered in Tokyo, Japan, Shibaura is a manufacturer of high-end plastic injection molding machines, auxiliary equipment, machine tools, and extrusion machines for molding plastic resins, as well as die-casting machines for casting aluminum and magnesium. The company operates in the market through four business segments, namely, Molding Machines, Machine Tools, Control Systems, and Others.

Shibaura serves its products across different industries, including automotive, manufacturing, medicine, and information and communications.

WITTMANN Technology GmbH (WITTMANN Group)

Founded in 1976 and headquartered in Vienna, Austria, WITTMANN is a manufacturing company providing industrial machinery and automation system equipment. The company manufactures injection molding machines, robots, and auxiliary equipment for plastic and non-plastic processing.

WITTMANN Group offers process technology with maximum energy efficiency in injection molding machines. Furthermore, the company offers a wide range of products, including robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers, and chillers.

Founded in 1935 and headquartered in Osaka, Japan, Kawata is engaged in designing and manufacturing powder and grain processing equipment and systems. The company offers a wide range of auxiliary equipment for plastic processing, including conveyors, blenders, dryers, temperature controllers, granulators, mixers, and material storage equipment. These equipment are used for molding, processing, and producing plastic products.

Kawata offers its equipment and systems to a large number of manufacturing sites. The company has a geographical presence across North America, East Asia, and Southeast Asia.

Maillefer

Founded in 2001 and headquartered in Vantaa, Finland, Maillefer is a manufacturer of wire, cable, pipe and tube production technologies and distributes extrusion and winding machinery. The company offers maintenance, performance and upgrade solutions.

Maillefer offers a wide range of products that include accumulators, cooling systems, CV line equipment, extruders, FO line equipment, stranders, and cable design systems. Furthermore, the company offers 50 technologies for the production process of building and automotive wires, fiber optic cables, voltage cables, rubber cables, LAN and coaxial cables, heating and plumbing pipes, micro-drip irrigation tubes, automotive tubes, medical tubes, micro-duct tubes, off-shore pipes and umbilicals, and special tubes.

Founded in 1959 and headquartered in Styria, Austria, Rosendahl is engaged in designing, manufacturing, and assembling production technologies for the battery, cable & wire, and optical fiber industries. In the cable & wire industry, the company offers extruders and crossheads used for cable insulation and cable jacketing.

Rosendahl’s extrusion equipment offer high linearity and high energy efficiency. The company has a geographical presence across the U.S., Austria, Russia, India, Finland, Switzerland, and China.

Moretto S.p.A.

Founded in 1980 and headquartered in Padua, Italy, Moretto is a market leader in producing automated systems for the plastics processing industry. The company is engaged in the research, development, and production of customized automation solutions for the plastics processing industry.

Moretto offers a wide range of products, including feeding & conveying, dehumidification, granulation, dosing, storage, temperature control, process cooling, supervision, and integrated systems. The company provides its products in various industries, including automotive, packaging, footwear, electrical & electronics, and medical.

Founded in 1964 and headquartered in Delhi, India, Bry-Air is engaged in the manufacturing of equipment used in dehumidification & environment control. The company is a leading provider of dehumidifiers, gas phase filtration, plastics drying and conveying, dry room, high-temperature waste heat recovery and energy-smart cooling solutions.

Bry-Air’s plastic auxiliary equipment include advanced drying, conveying, and mold dehumidification solutions for injection moulding and extrusion in the plastics processing industry. The company provides its products to various industries, including food processing, pharmaceuticals, lithium battery manufacturing, cold stores, data centers, and plastics processing.

Reynold India Private Limited

Founded in 1995 and headquartered in Uttar Pradesh, India, Reynold is a manufacturer of process chillers. The company’s product portfolio comprises advanced screw chillers, versatile scroll chillers, and rugged reciprocating chillers for peculiar process cooling applications.

Reynold also manufactures and supplies plastic auxiliary equipment such as hopper loaders, dehumidifying dryers, and hopper dryers, among others. The company has a presence across India, Bangladesh, UAE, the U.S., and Malaysia through its subsidiaries and a strong distribution network.