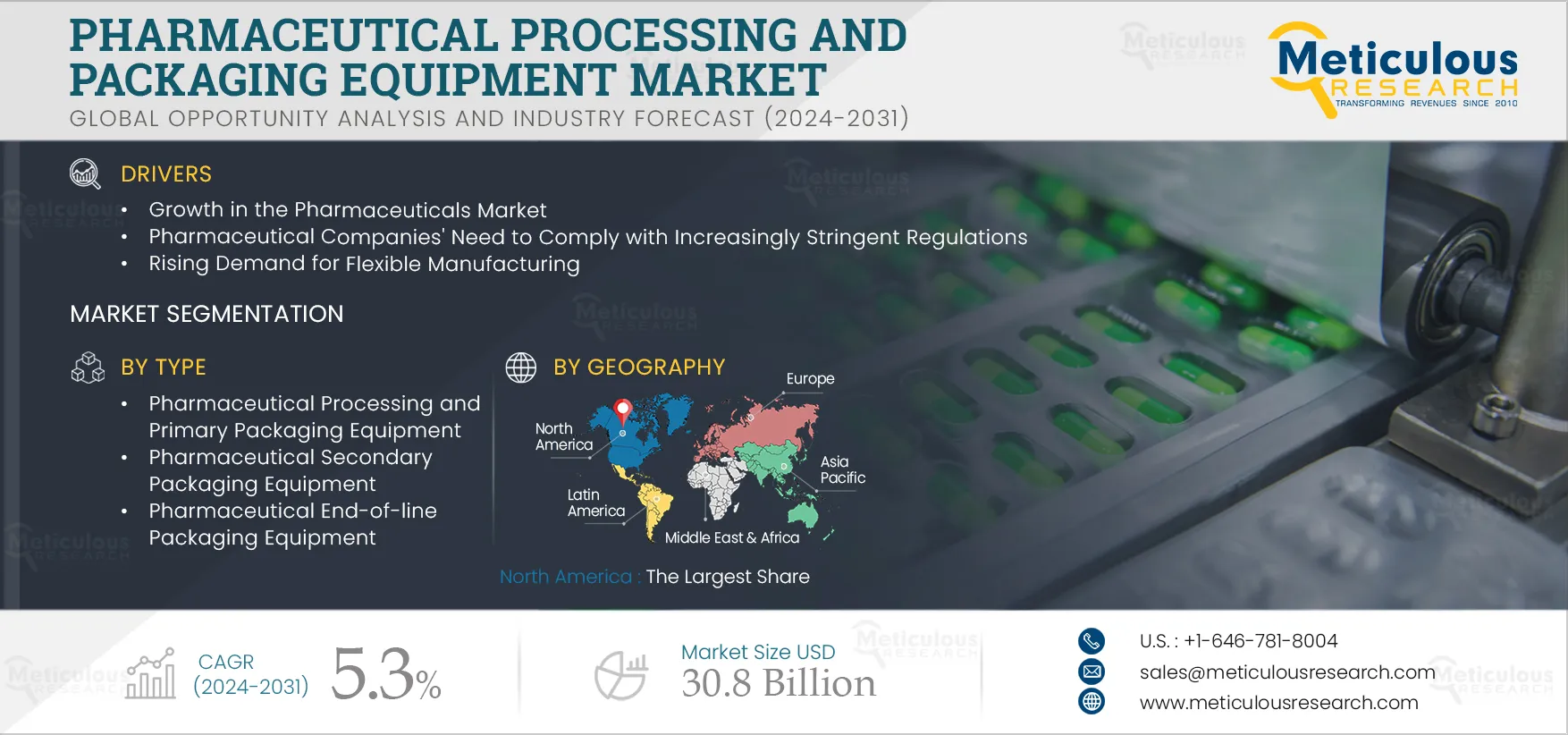

The Pharmaceutical Processing and Packaging Equipment Market is expected to grow at a CAGR of 5.3% from 2021 to 2028 and is expected to reach $30.8 Billion by 2031. Pharmaceutical processing and packaging equipment are used for different operations in processing such as blending, mixing, granulating, milling, cleaning, and sterilizing; and in packaging such as filling, counting, and labeling. Significant growth in the pharmaceutical market can be attributed to the increasing burden of chronic & infectious diseases amid the increasing geriatric population. The demand for contract manufacturing and flexible manufacturing further contributes to market growth.

The expansion of domestic manufacturing capacities of pharmaceuticals in various countries such as China, India, Malaysia, Indonesia, and UAE and the increase in the pharma R&D spending offer growth opportunities for the pharmaceutical processing and packaging market.

Here are the top 10 companies operating in the Pharmaceutical Processing and Packaging Equipment Market

IDEX Corporation

IDEX Corporation operates its business in three segments: Fire & Safety/Diversified Products, Fluid & Metering Technologies, and Health & Science Technologies. The Health & Science Technologies segment is further divided into five subsegments: Scientific Fluidics & Optics, Sealing Solutions, Gast, Micropump, and Material Processing Technologies. The Material Processing Technologies subsegment provides equipment for pharmaceutical processing and packaging. The Health & Science Technologies segment caters to the food and beverage, pharmaceutical, automotive semiconductors, electronics, cosmetics, and other industries. The company’s subsidiaries offering products in the pharmaceutical processing and packaging equipment market are Fitzpatrick Co. Inc. (Canada), Quadro Engineering Corp. (Canada), Microfluidics International Corporation (U.S.) Steridose (Sweden), and Matcon Limited (U.K.). These subsidiaries have a presence in more than 80 countries, including the U.S., Canada, India, the U.K., and China.

Founded in 1967 and headquartered in Ilshofen, Germany, Bausch+Ströbel operates as a filling and packaging supplier for the pharmaceutical industry. The company specializes in filling syringes, vials, cartridges, and ampoules with high-grade liquid and powder pharmaceutical products. The company has its geographic presence in various countries, including the U.S., Russia, Bangladesh, Argentina, France, and Austria. Some of the company’s subsidiaries are Wilco AG (Switzerland), Bausch+Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG. (Germany), and Bausch+Strobel Machine Company, Inc. (U.S.).

Founded in 1973 and headquartered in Ontario, Canada, ACIC Pharmaceuticals Inc. is a pharmaceutical and chemical company that provides active pharmaceutical ingredients, contract manufacturing services, finished dosage forms, regulatory services, process development and optimization, and clinical services. The company operates through five divisions: API, Injectable, Pharmaceutical Machinery, Specialty Pharmaceuticals, and Regulatory. The company’s subsidiary ACIC Machinery distributes products, including filling/inspection systems, sterilization tunnels, washing machines, automation, handling systems, barrier isolation systems, water technologies, processing systems, and engineering services through its Pharmaceutical Machinery division.

The company has its geographic presence across North America, Asia Pacific, Latin America, Europe, and other countries. Some of the subsidiaries of ACIC Pharmaceuticals Inc. providing pharmaceutical machinery are ACIC Pharmaceutical Machinery (Canada), ACIC Europe (Cyprus), ACIC (U.S.).

Korber AG

Founded in 1946 and headquartered in Hamburg, Germany, Korber AG is an international technology company that operates across five business areas: Tissue, Tobacco, Pharma, Supply Chain, and Digital. The Pharma business segment of the company provides solutions for efficient and safe inspection, manufacturing, handling, and packaging of pharmaceuticals and traceability solutions. The company is also involved in the development, production, and marketing of various automation products and services. The Körber Pharma Business is present across 100 locations globally. Additionally, the Körber Business Area Pharma has aggregated the leading pharma and biotech companies such as Fargo Automation, Inc. (U.S.), Dividella AG (Switzerland), Rondo-Pak LLC (U.S.), Mediseal GmbH (Germany), SeidenaderMaschinenbau GmbH (Germany), Systec & Services GmbH (Germany), and Werum IT Solutions (Germany) under the Korber brand. The major subsidiaries of the company operating in the global pharmaceutical processing equipment business are Fargo Automation, Inc. (U.S.), Dividella AG (Switzerland), Rondo-Pak LLC (U.S.), Mediseal GmbH (Germany), and SeidenaderMaschinenbau GmbH (Germany).

MAQUINARIA INDUSTRIAL DARA, SL

Founded in 1996 and headquartered in Barcelona, Spain, MAQUINARIA INDUSTRIAL DARA, SL provides advanced technological equipment to the pharmaceutical, biotech, and cosmetic industries. The company provides equipment for washing, sterilizing, filling, closing, freeze-drying, and other applications. MAQUINARIA INDUSTRIAL DARA, SL has a geographic presence in approximately 80 countries across Europe, the Middle East & Africa, the Americas, and Asia. The company has installed over 1,200 equipment globally. The company’s partners are Thermo Fisher Scientific Inc. (U.S.), Becton Dickinson and Company (U.S.), and Aptar Pharma Inc. (U.S.).

Marchesini Group S.p.A.

Founded in 1974 and headquartered in Bologna, Italy, Marchesini Group S.p.A. is engaged in designing and manufacturing personalized packaging machinery used in the pharmaceutical and cosmetic industries. The company’s production segment has two divisions: Pharmaceuticals and Beauty. The company produces machinery for different pharmaceutical products like aseptic liquids, powder, solid, and creams through its Pharmaceutical segment. The company also manufactures packaging lines for the pharmaceutical and cosmetic industries. Marchesini Group S.p.A. has a geographic presence across North America, Europe, Asia Pacific, and the Middle East & Africa. The company offers its products to over 116 countries globally. Additionally, the company has a direct presence across 68 counties globally through its subsidiaries. Marchesini Group S.p.A. has 35 sales agencies globally to assist in its sales activities. Some of the company’s subsidiaries operating in the pharmaceutical processing and packing equipment market are Multipack (Italy), Vibrotech Srl (Italy), Dott. Bonapace& C. Srl (Italy), CMP Pharma (U.S.), SEA Vision s.r.l. (Italy), and Schmucker S.R.L (Italy).

Syntegon Technology GmbH

Founded in 1861and headquartered in Baden-Württemberg, Germany, Syntegon Technology GmbH is a global supplier of processing and packaging equipment in the pharmaceutical, medical device, and food industries. The company provides solutions for process technology, solid dosage forms, liquid dosage forms, inspection technologies, and secondary packaging to pharmaceutical companies.

Bosch Packaging Technology (Robert Bosch GmbH), a former bussiness unit of Bosch Group, was acquired by CVC Capital Partners (Luxembourg) in December 2019 to form Syntegon Technology GmbH. Before December 2019, Robert Bosch GmbH operated its business through four segments: Mobility Solutions, Industrial Technology, Energy and Building Technology, and Consumer Goods. The Industrial Technology segment of the company is further segmented into—Robert Bosch Manufacturing Solutions, Packaging Technology, and Drive and Control Technology.

The company operated in the pharmaceutical processing and packaging equipment market through its Packaging Technology segment. Syntegon Technology GmbH has over 6,100 associates across 30 locations in over 15 countries. The company has its presence in countries such as Thailand, the U.K., Germany, China, South Africa, and India. Syntegon Pharma Technology, LLC (U.S.), Syntegon Technology (Thailand) Co., Ltd. (Thailand), Syntegon Technology Ltd. (Egypt), and Syntegon Technology K.K. (Japan) are some subsidiaries of the company offering products for the pharmaceutical processing and packaging equipment market.

ANTARES VISION S.p.A.

Founded in 2007 and headquartered in Brescia, Italy, ANTARES VISION S.p.A. is engaged in designing, manufacturing, installing, and maintaining innovative serialization and high-performance inspection systems and machines. The company’s production lines are equipped with proven turnkey solutions for serialization and aggregation. ANTARES VISION S.p.A. is involved in the R&D, study, design, construction, and installation of track & trace solutions for the traceability of products. The company operates its business through two segments: Life-Science and Extra Life-Science. The company operates in the pharmaceutical processing and packaging equipment market through its Life-Science segment. ANTARES VISION S.p.A. has its geographic presence across Europe, North America, South/Central America, Asia/Middle East, and Africa.

The company has 2,196 production lines deployed in 200 production plants globally. The company has established a network of over 40 partners, and it serves more than sixty countries globally. Convel (Italy), Antares Vision Asia Pacific Ltd. (China), Antares Vision Do Brasil (Brazil), and Antares Vision North America (Canada) are some subsidiaries of the company.

Coesia S.p.A.

Coesia S.p.A. is a holding company. The company and its subsidiaries are involved in the construction, design, and sales of automated machinery used in the production, packing & packaging of consumer goods, food, and pharmaceutical sectors. The company’s products are also used for various applications, including processing tobacco, fume quality control, aseptic filling, and package opening. Coesia S.p.A. operates its business through three major segments: Advanced Automated Machinery & Materials (AAM&M), Industrial Process Solutions (IPS), and Others, which include the operations of CIMA S.p.A. (Italy). The company operates in the pharmaceutical processing and packaging equipment market through its Advanced Automated Machinery & Materials (AAM&M) and Industrial Process Solutions (IPS) segments. The Advanced Automated Machinery & Materials (AAM&M) segment is involved in the production, packaging & packing of machinery used in tobacco, consumer goods, food, ceramics, single-use hygiene, and the pharmaceutical industry. The Industrial Process Solutions (IPS) segment is involved in the production, construction, design of automation solutions such elevators, transformers, depalletizers, palletizers, and printing and packaging solutions. The segment is also involved in providing the sale of logistics solutions.

Freund Corporation

Freund Corporation is involved in the manufacturing of machinery, excipients, and food preservatives. The company also manufactures machinery that is used in the processing of pharmaceuticals. The company operates its business through two major segments: Machinery Business Segment and Chemicals Business Segment. The Machinery Business Segment of the company offers equipment for coating and granulating used in pharmaceutical, food, cosmetics, and other industries. Subsequently, the company operates in the pharmaceutical processing and packaging equipment market through its Machinery Business Segment. Freund Corporation has its geographic presence across North America, Latin America, Europe, Africa, Japan, Oceania, and Asia. The company has its head offices located in Japan.

The company states that it has more than 300 international and domestic intellectual properties that enable the company to create innovative products. The Freund group of companies have installed over 8000 equipment across the world. The company’s subsidiaries offering products for the pharmaceutical processing and packaging equipment market are Freund-Vector Corporation (U.S.), Freund Turbo Corporation (Japan), Parle FREUND Machinery Private Limited (India), and Cos.Mec s.r.l. (Italy).

Popular Mentions: Truking Technology Limited (China), GEA GROUP (Germany), I.M.A INDUSTRIA MACCHINE AUTOMATICHE S.P.A (Italy), LINXIS GROUP (France), OPTEL GROUP (Canada), JEKSON VISION (India), Kevin Process Technologies Pvt. Ltd. (India), KIKUSUI SEISAKUSHO LTD. (Japan), KORSCH AG (Germany), M.A.R. S.p.A. Macchine Automatiche Riempitrici (Italy), OPTIMA packaging group GmbH (Germany), Wenzhou Trustar Machinery Technology Co. Ltd (China), Sainty Co (China), ACG (India), BREVETTI CEA S.P.A (Italy), Cadmach Machinery Co. Pvt. Ltd (India), CAM Packaging IT (Italy), Fette Compacting (Germany), Glatt GmbH (Germany), Harro Höfliger Verpackungsmaschinen GmbH (Germany), Uhlmann Pac-Systeme GmbH & Co. KG (Germany), and Tecnomaco Italia SRL (Italy)