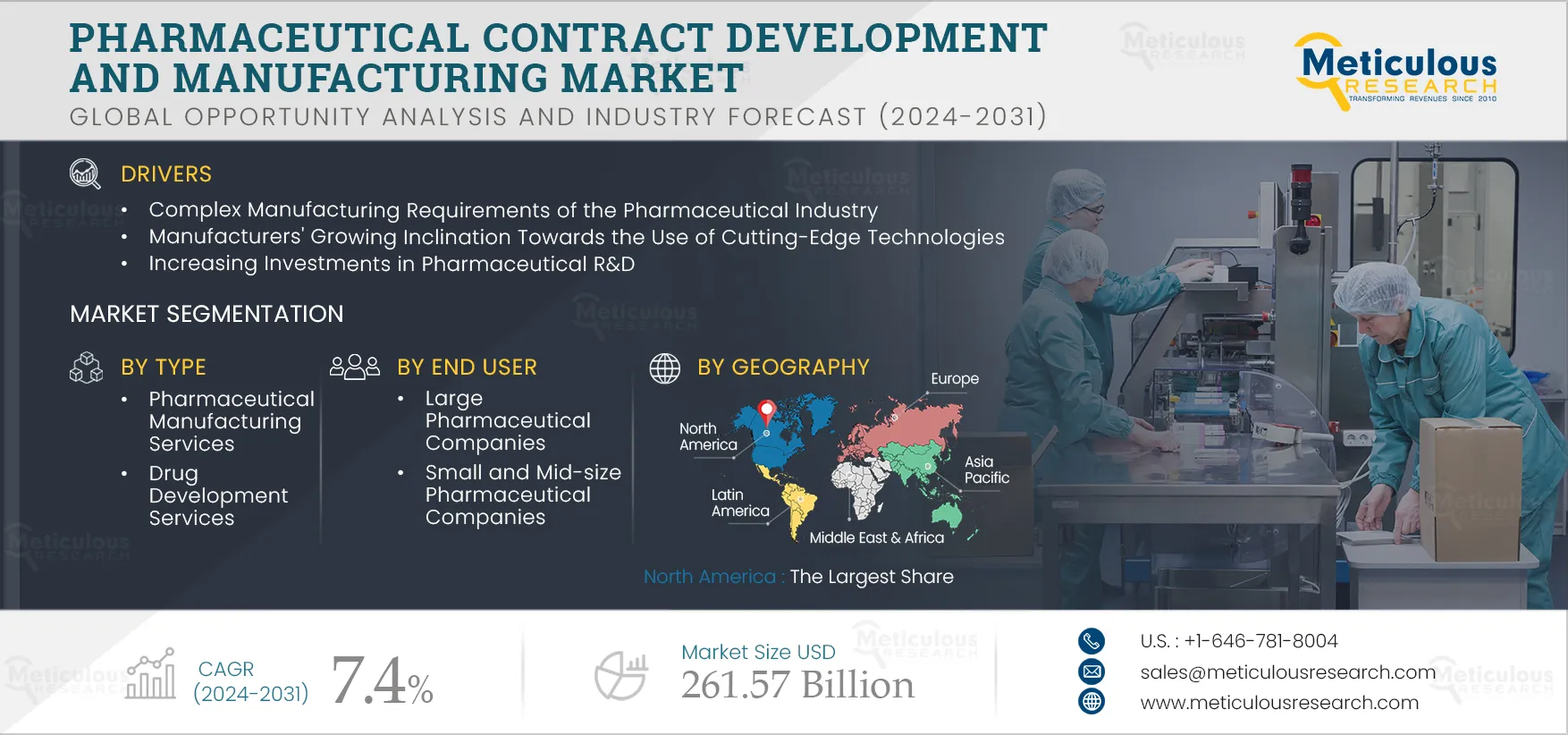

The Pharmaceutical Contract Development and Manufacturing Market is expected to grow at a CAGR of 7.4% from 2024 to 2031 to reach $261.57 billion by 2031. Pharmaceutical contract development and manufacturing market includes pharmaceutical manufacturing services, drug development services, and biologics manufacturing services. The growth of this market is mainly attributed to factors such as complex manufacturing requirements of the pharmaceutical industry, manufacturers’ growing inclination towards the use of cutting-edge technologies, patent expiration, increasing investments in pharmaceutical R&D, the rising demand for generic medicines and biologics, and the outbreak of the COVID-19 pandemic.

Here are the top 10 companies operating in the Pharmaceutical Contract Development and Manufacturing Market

Lonza Group Ltd (Switzerland)

Founded in 1952 and headquartered in Basel, Switzerland; Lonza Group is a life science-driven chemical company that supplies active ingredients, chemical intermediates, and biotechnology solutions to the pharmaceutical and agrochemical industries. The company also offers a catalog of organic intermediates for various applications, such as pharmaceuticals, agrochemicals, vitamins, food and feedstuff, dyes and pigments, adhesives, and fragrances. It also manufactures specialty biocides and oleochemicals; and develops and produces specific polymer intermediates, unsaturated polyester-resins, compounds, and composites.

The company has a direct presence through research and development and manufacturing sites in Europe, North and Central America, Latin America, Asia, Africa, Australia, New Zealand, and other countries.

Catalent, Inc. (U.S.)

Founded in 2007 and headquartered in New Jersey, U.S. Catalent provides different products and services for development sciences, delivery technologies, and multi-modality manufacturing. The company works with life science customers to develop, launch, and supply pharmaceuticals, biologics, cell and gene therapy, and health products. Catalent offers development and manufacturing; formulation; and development services in pharmaceutical contract development and manufacturing market.

The company has a direct presence through R&D and manufacturing sites in Asia-Pacific, Europe, Latin America, and North America. The company offers pharma services through its Paragon BioServices Inc. (U.S.) and Catalent Cell and Gene Therapy (U.S.) subsidiaries.

Thermo Fisher Scientific, Inc. (U.S.)

Founded in 2006 and headquartered in Massachusetts, U.S., Thermo Fisher Scientific offers products and services in pharmaceutical, biotechnology, agricultural, clinical, healthcare, and government markets. The company operates through four segments: Life Sciences Solutions, Analytical Instruments, Specialty Diagnostics, and Laboratory Products and Biopharma Services. It offers pharmaceutical contract development and manufacturing services through the Pharma Services segment of the Laboratory Products and Biopharma Services business division.

The company has a direct presence through its regional offices and production sites in various countries, including the U.S., Mexico, Brazil, Germany, Belgium, Austria, the U.K., Italy, the Netherlands, South Africa, the UAE, India, China, Japan, Australia, and the Republic of Korea.

Samsung Biologics Co., Ltd. (South Korea)

Founded in 2011 and headquartered in Incheon, South Korea, Samsung Biologics provides contract manufacturing, contract development, and clinical research services equipped with a batch production system for biopharmaceuticals. The company’s contract development business focuses on providing services for cell lines to initial clinical trials, including cell line development, process development, and formulation/analysis methodology. The clinical research business of the company offers services for the exploration of drug candidate materials, biological stability/toxicity analysis in cell line development, and homogeneity verification & cell storage.

The company has a presence in the U.K., Germany, Japan, Australia, Nigeria, China, Canada, the U.S., Puerto Rico, Brazil, Indonesia, and Singapore, among others.

Recipharm AB (Sweden)

Founded in 1995 and headquartered in Sweden; Recipharm is a pharmaceutical contract development and manufacturing organization. The company’s major products and services include nasal sprays, auto-injectors, medical check valves, inhalations solutions, custom development, custom manufacturing, and generic APIs. The company operates through four business segments, namely, Advanced Delivery Systems, Manufacturing Sterile, Manufacturing Solids & Others, and Development & Licensing. The company offers its pharmaceutical products and services through its subsidiary Recipharm Pharmaceutical Development AB (Sweden) and RPH Pharmaceuticals AB (Sweden).

The company has direct presence through its production facilities across Sweden, France, Germany, Italy, Spain, Portugal, India and the U.K. and development facilities across Sweden, France, Italy, India, Israel, and the U.S.

FUJIFILM Diosynth Biotechnologies (Japan)

Established in 1934 and headquartered in Tokyo, Japan, FUJIFILM Diosynth Biotechnologies is involved in developing and manufacturing active ingredients for pharmaceutical companies. The company operates through four segments: Healthcare, Business Innovation, Imaging, and Materials. The company offers cell culture services, microbial fermentation services, and viral vector & vaccine services through its Bio CDMO business segment of the Healthcare division. The company also offers additional fill-finish, process characterization, and validation services.

FUJIFILM has facilities in the U.S., Denmark, China, Southeast Asia, and the U.K. The company has five bio CDMO facilities in Europe and the U.S. The company operates through the Healthcare business segment (sub-segment of Healthcare and Material Solutions) of its parent company FUJIFILM Holdings Corporation (Japan).

Siegfried Holdings AG (Switzerland)

Founded in 1873 and headquartered in Zofingen, Switzerland, Siegfried Holdings is a pharmaceutical company that offers and manufactures primary and secondary drug substances and products. It develops and manufactures active pharmaceutical ingredients for pharmaceutical clients with research and development programs, related intermediates, and controlled substances. The company also develops and produces finished dosage forms, including sterile fillings.

Siegfried has manufacturing facilities in Switzerland, the U.S., Malta, China, Germany, France, and Spain.

C.H. Boehringer Sohn AG & Co. KG (Germany)

Founded in 1885 and headquartered in Ingelheim am Rhein, Germany C.H. Boehringer Sohn is a biopharmaceutical company that focuses on the therapeutic areas of cardiovascular disease, respiratory diseases, diseases of the central nervous system, metabolic diseases, virological diseases, and oncology. The company operates through four segments, namely, Human Health, Animal Health, Biopharma Contract Manufacturing, and Science & Innovation. The Biopharma Contract Manufacturing segment offers joint development, launch, and manufacturing activities for biopharmaceutical products; contract development and manufacturing for clinical and commercial biopharmaceuticals for the external customers; and process transfer within the global biopharmaceutical supply network.

The company has production facilities in the U.S., Spain, Brazil, Italy, Mexico, Germany, Greece, Japan, Austria, Indonesia, and China. Boehringer Ingelheim’s Biopharmaceutical Contract Manufacturing business is known under the brand name Boehringer Ingelheim BioXcellence.

Jubilant Pharmova Limited (Limited)

Founded in 1978 and headquartered in Uttar Pradesh, India, Jubilant Pharmova Limited, previously known as Jubilant Life Sciences Limited, is an integrated pharmaceutical and life sciences company engaged in pharmaceuticals, life science ingredients, drug discovery solutions, and branded pharmaceuticals. Jubilant Life Sciences operates in three business segments: Pharmaceuticals, Life Science Ingredients, and Drug Discovery and Development Solutions. In February 2021, Life Science Ingredients segment demerged from Jubilant Life Sciences Limited to Jubilant Ingrevia Limited, and the name of Jubilant Life Sciences Limited was changed to Jubilant Pharmova Limited. Jubilant Pharmova Ltd. offers services and products in research and manufacturing.

The company has R&D and manufacturing sites in India, Belgium, China, the U.S., and Canada. The subsidiaries of the company operating in the CDMO market are Jubilant Biosys Limited (India), Jubilant Pharma Limited (Singapore), Jubilant HollisterStier LLC (U.S.), and Jubilant Generics Ltd. (India).

Fareva SA (Luxembourg)

Founded in 1985 and headquartered in Luxembourg, Fareva SA is a subcontractor in the industrial & household, cosmetics, and pharmaceutical fields. The company operates through five divisions, namely, Pharmaceuticals, API, Beauty, Makeup, Household, and Industrial. Fareva offers complete drug development and manufacturing services for APIs and intermediate active ingredients, highly potent APIs, sterile APIs, cytotoxiques drugs, and hormones and steroids. The company’s API division has a direct presence through manufacturing sites in France and Germany.