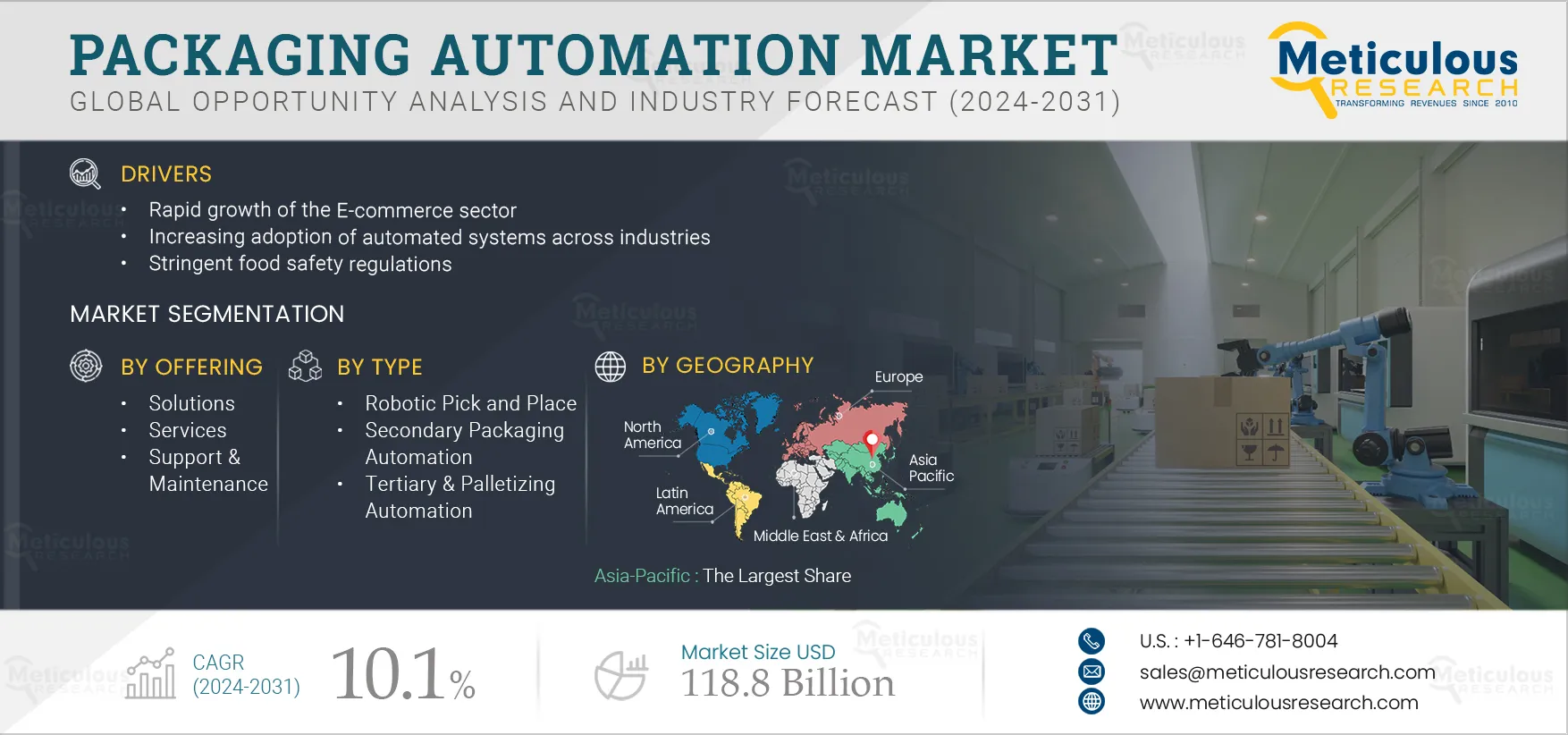

The Packaging Automation Market is expected to reach USD 118.8 billion by 2031, at a CAGR of 10.1% during the forecast period (2024–2031). The growth of the packaging automation market is driven by the rapid growth of the e-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations around the globe. However, the high costs of implementing packaging automation solutions restrain the growth of this market. Additionally, the high demand for packaging automation in the logistics industry and the increasing need for sustainable and eco-friendly packaging are expected to generate growth opportunities for the players operating in this market. However, the shortage of skilled operators is a major challenge for market growth.

Here are the top 10 companies operating in the Packaging Automation Market

Founded in 1988 and headquartered in Zürich, Switzerland, ABB is a pioneering technology leader offering solutions to utility, industrial, transportation, and infrastructure sectors. The company operates mainly in robotics, power, heavy electrical equipment, and automation technology.

The company provides various products such as control room solutions, drives, electric vehicle charging infrastructure, industrial software, low voltage products and systems, measurement and analytics, medium voltage products, metallurgy products, motors and generators, PLC automation, power converters and inverters, and robotics. Through this, the company provides packaging solutions for its medium-voltage products. ABB packaging and solutions offer a diverse electrification distribution portfolio that addresses the global demand for reliable power. ABB caters to different industries, including aluminum, automotive, buildings and infrastructure, cement, channel partners, chemical, data centers, food and beverage, life sciences, marine, metals, mining, oil and gas, ports, power generation, printing, process automation, pulp and paper, railway among others. The company operates through four business segments: Electrification, Motion, Process Automation, and Robotics & Discrete Automation.

The company operates through four reportable business segments: Electrification, Motion, Process Automation, and Robotics & Discrete Automation. Some of its subsidiaries are ABB Inc. (U.S.), ABB Limited (U.K.), Asea Brown Boveri Lanka (Private) Limited (Sri Lanka), Asea Brown Boveri Ltd. (Mauritius), ABB Technologies Ltd. (Israel), and ABB Global Industries and Services Private Limited (India). Through its subsidiaries and strong distribution network, the company has a strong geographic presence across the Americas, Europe, Asia, and the Middle East & Africa. As of December 2022, the company had a headcount of 105,000 employees globally.

Bosch Rexroth GmbH (A Subsidiary of Robert Bosch GmbH)

Established in 1795 and headquartered in Stuttgart, Germany. Bosch Rexroth is a leading provider of automation solutions for industrial and mobile applications. The company is an automation supplier and manufacturing company. It designs, develops, and manufactures products, including assembly systems and technologies; electric drives and controls; industrial hydraulic solutions; linear motion technology solutions; mobile hydraulics devices, including pumps, motors, and gears; molding and casting technologies; pneumatic systems; tightening systems and technologies, and resistance welding components and technologies. The company also offers several services, such as technical services, repair, consulting, and training. It offers its products for mobile applications, machinery applications and engineering, and factory automation.

Robert Bosch GmbH operates through five business segments: Mobility Solutions, Industrial Technology, Consumer Goods, Energy and Building Technology, and Others. The company has a geographic presence across Europe, the Americas, Asia, and Other regions. As of December 2022, the company had a headcount of 421,338 employees globally.

Founded in 1996 and headquartered in California, U.S., Juniper Networks, Inc. is helping customers to build the most. Founded in 1847 and headquartered in Munich, Germany, Siemens AG’s operations encompass automation and digitalization in the process and manufacturing industries, intelligent infrastructure for buildings and distributed energy systems, rail transport solutions, and health technology and digital healthcare services. The company provides various products & services, including Siemens Xcelerator, building technology, drive technology, energy, financing, healthcare, industrial automation, and mobility, among others.

The company caters to different industries, including aerospace, airports, automotive manufacturing, battery manufacturing, chemical industry, cement, commercial buildings, cranes, and data centers. The company operates through five reportable business segments: Digital Industries, Smart Infrastructure, Mobility, Siemens Healthineers, and Siemens Financial Services (SFS). Some of its subsidiaries are Siemens Mobility (Germany), Siemens Canada Limited (Canada), Siemens Building Technologies (Switzerland), and Siemens Mexico (Mexico). Through its subsidiaries and strong distribution network, the company has a strong geographic presence across Europe, C.I.S., Africa, the Middle East, the Americas, Asia, and Australia. As of September 2022, the company had a headcount of 49,000 employees globally.

Fanuc Corporation

Established in 1972 and headquartered in Yamanashi, Japan, Fanuc Corporation is a leading provider of innovation and reassurance manufacturing solutions for robots and robomachines. The company provides products for factory automation, such as CNCs, compact machining, electric injection molding machines, and wire electrical discharge machines.

The company serves customers in over 100 countries and more than 260 service locations throughout the world. The company operates through four business segments: FA, ROBOT, ROBOMACHINE, and Service. With its subsidiaries and strong distribution network, the company has a presence across Japan, the Americas, Europe, China, Asia, and Other. Some of its subsidiaries are FANUC America Corporation (U.S.), FANUC Europe Corporation (Luxembourg), Korea Fanuc Corporation (Korea), and Taiwan Fanuc Corporation (Taiwan). As of March 2022, the company had a headcount of 8,675 employees globally.

Mitsubishi Electric Corporation

Founded in 1921 and headquartered in Tokyo, Japan, Mitsubishi Electric Corporation is a global leader in the manufacture and sales of electric and electronic equipment. This equipment is used in energy and electric systems, industrial automation, information and communication systems, electronic devices, and home appliances. The company offers a business of public utility systems, energy systems, defense & space systems, factory automation systems, automotive equipment, building systems, air conditioning systems & home products, information systems & network services, and semiconductor & devices.

Mitsubishi Electric offers integrated, secure, end-to-end electrical infrastructure, cooling, performance management, and energy optimization solutions for data centers. The company caters to various industries, including automotive, commercial fan/pump, machine tool, material handling, metal, paper converting, oil and gas, packaging automation, power and water, printing and converting, robotics, and semiconductors.

The company operates through five reportable business segments: Infrastructure, Industry and Mobility, Life, Business Platform, and Other. Some of its subsidiaries are Mitsubishi Electric Engineering (Japan), TMEIC (Japan), Mitsubishi Electric United States (U.S.), SPC Electronics Corporation (Japan), and Kodensha, Co., Ltd. (Japan), among others. Through its subsidiaries and strong distribution network, the company has a strong geographic presence across Japan, North America, Asia, Europe, and Others. As of March 2023, the company had a headcount of 149,655 employees worldwide.

WestRock Company

Founded in 2015 and headquartered in Atlanta, Georgia, WestRock is a leader in manufacturing automated packaging machinery. The company provides sustainable fiber-based paper and packaging solutions. WestRock company is the largest manufacturer of solid fiber partitions in North America. The company offers folding cartons that package items such as food, paper, beverages, dairy products, tobacco, confectionery, health & beauty, and other household consumer, commercial, and industrial products. The company manufactures express mail packages for the courier industry and provides inserts & labels, rigid packaging, and other printed packaging products, such as transaction cards (including credit and debit cards), brochures, product literature, marketing materials (including booklets, folders, inserts, cover sheets, and slipcases) and grower tags and plant stakes for the horticultural market. The company operates in North America, South America, Europe, Asia, and Australia.

WestRock operates through four business segments: Corrugated Packaging, Consumer Packaging, Global Paper, and Distribution. With its subsidiaries and a strong distribution network, the company has a presence across the U.S., Canada, Latin America, EMEA, and Asia Pacific. Some of its subsidiaries are Gondi, S. de R.L. de C.V. (Mexico), Kapstone LLC (U.S.), and Westrock Charleston Kraft, LLC (U.S.). As of September 2022, the company had a headcount of 50,500 employees globally.

Founded in 1871 and headquartered in Rueil-Malmaison, France, Schneider Electric SE is a global leader in the digital transformation of energy management and automation. The company provides various products for different applications, including residential and small businesses, building automation and control, low voltage products and systems, solar and energy storage, access to energy, medium voltage distribution and grid automation, critical power, cooling and racks, and industrial automation and control. The company caters to different end-use industries, including automotive and eMobility, cloud and service providers, commercial real estate, data center and network solutions, energies and chemicals, facility management, food and beverage, healthcare, hotels, industrial automation solutions, life sciences, logistics, and warehouse, machinery, marine, mining, minerals, and metals among others. The company offers sustainable and efficient smart packaging machines with EcoStruxure solutions.

The company operates through two reportable business segments: Energy Management and Industrial Automation. Some of its subsidiaries are Telemecanique (Ireland), AVEVA Group plc (U.K.), Square D (U.S.), Luminous Power Technologies (India), and Schneider Electric (Australia) Pty Ltd (Australia). Through its subsidiaries and strong distribution network, the company has a strong geographic presence across North America, Western Europe, Asia Pacific, and the rest of the world. As of December 2022, the company had a headcount of 1,35,000 employees worldwide.

Brenton, LLC (A Part of Pro Mach, Inc.)

Founded in 1987 and headquartered in Minnesota, U.S., Brenton is a part of Pro Mach, Inc. (U.S.) and is a global leader in designing and manufacturing integrated end-of-line case packaging systems and machines. The company provides solutions for the consumer-packaged goods, food, beverage, pharmaceutical, and medical device industries. The company designs and manufactures customer-driven applications in robotic systems, including material handling and high-speed pick and place, case packing, palletizing, and integrated end-of-line systems. Brenton offers palletized packaging solutions for case-packing equipment, shrink-wrapping machines, and robotic packaging systems. The company provides mechanical and electrical services for new machines, modifications to existing equipment, and emergency services.

Swisslog Holding AG (A Part of KUKA AG)

Founded in 1900 and headquartered in Buchs, Switzerland, Swisslog Holding AG is a leading global supplier of intelligent automation solutions. Swisslog Holding AG is a subsidiary of KUKA Aktiengesellschaft (KUKA AG) (Germany). The company has a broad product portfolio of key technologies, such as conveyor systems, ASRS, AGVs, shuttle systems, monorails, robotics, and warehouse management software. The company also provides innovative solutions & services, including consulting, project implementation, customer service, best-in-class technologies, and software.

Swisslog offers a wide range of traditional and advanced technologies for automated storage and retrieval of pallets and smaller goods, such as cartons or bins. These fully automated systems boost warehouse quality, flexibility, and efficiency. The company’s offerings cater to different industries, including food & beverage, pharmaceuticals, retail, and E-commerce.

KUKA AG operates through five reportable segments: Systems, Robotics, Swisslog, Swisslog Healthcare, and China. Some of its subsidiaries are Reis Robotics (Germany), KUKA Roboter CEE GmbH (Germany), Thompson Friction Welding (U.K.), KUKA Robotics China Co., Ltd. (China), and Reis Group Holding Gmbh & Co. Kg (Germany). With its subsidiaries and a strong distribution network, the company has a geographical presence across EMEA, the Americas, and Asia-Pacific. As of December 2022, the company had a headcount of 15,064 employees worldwide.

Rockwell Automation, Inc.

Founded in 1903 and headquartered in Armonk, New York, U.S., Rockwell Automation, Inc. is an American provider of industrial automation and digital transformation technologies. The company provides various products such as motion control, motor control, network security & infrastructure, packaged solutions, power supplies, programmable controllers, push buttons & signaling devices, relays & timers, safety instrumented systems, safety products, sensors & switches, and signal interface. Rockwell Automation caters to industries including aerospace, automotive & tire, cement, chemical, entertainment, fiber & textiles, food & beverage, household & personal care, hydrogen, infrastructure, and life sciences.

The company operates through three reportable business segments: Intelligent Devices, Software & Control, and Lifecycle Services. Some of its subsidiaries are Allen-Bradley (U.S.), Plex Systems, Inc. (U.S.), Rockwell Automation GmbH (Germany), Automation Control Products, Inc. (U.S.), Sensia LLC (U.S.), Emulate3d, Inc. (U.K.) among others. Through its subsidiaries and strong distribution network, the company has a strong geographic presence across North America, Europe, the Middle East and Africa, Asia Pacific, and Latin America. As of September 2022, the company had a headcount of approximately 26,000 employees globally.