Resources

About Us

Masterbatch Market Size, Share, Forecast, & Trends Analysis by Product (Color, Additive, White, Black), Type (Biodegradable), Polymer (PE, PA, PP, PVC, PS, PUR, PET, PVDF), End User (Consumer Electronics, Packaging) - Global Forecast to 2032

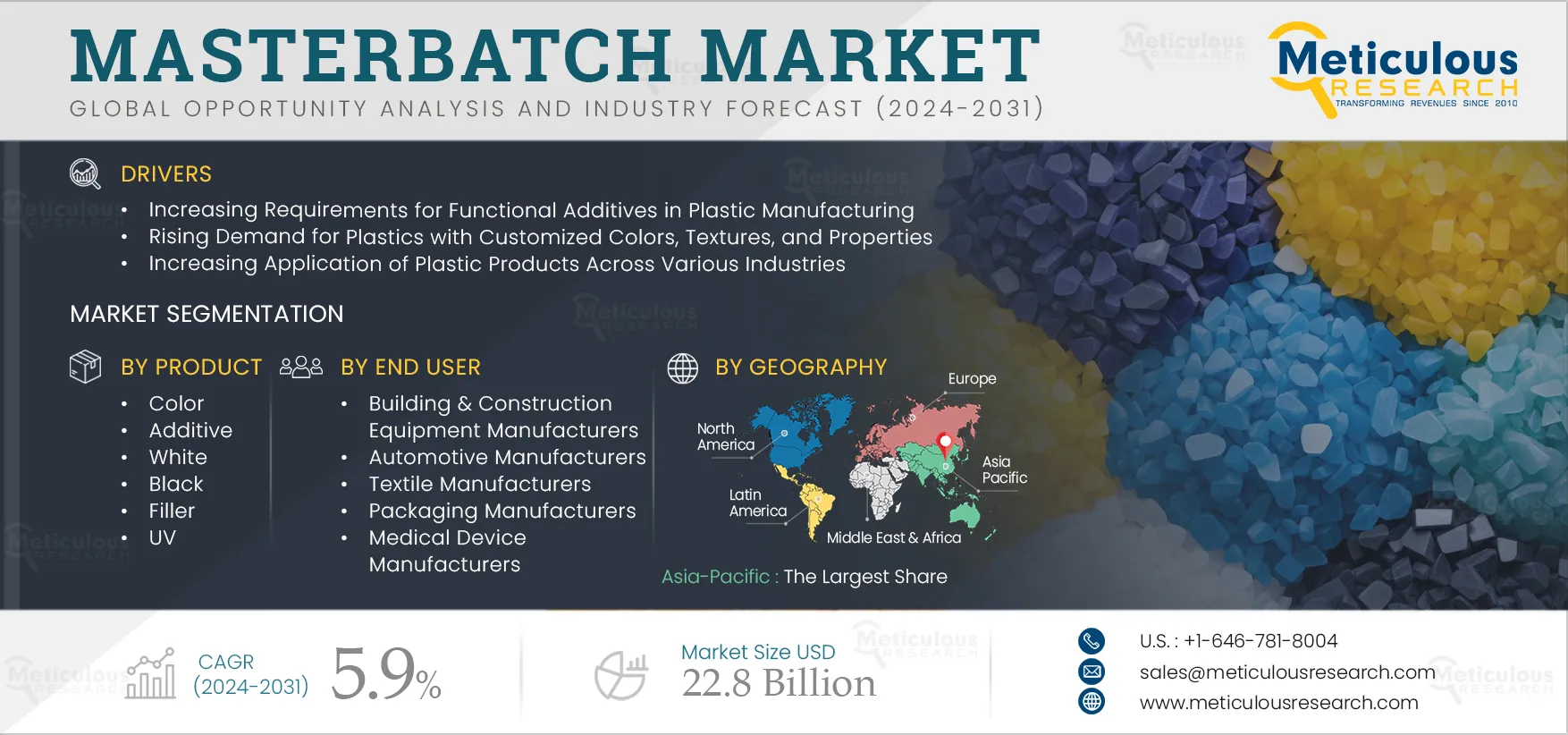

Report ID: MRCHM - 1041166 Pages: 210 May-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe Masterbatch Market is expected to reach $22.8 billion by 2032, at a CAGR of 5.9% from 2025 to 2032. The growth of this market is primarily driven by the increasing requirements for functional additives in plastics manufacturing, the rising demand for plastics with customized colors, textures, and properties, and the increasing application of plastic products across various industries. However, growing awareness regarding environmental pollution due to plastics restrains the growth of this market. Additionally, the increasing demand for biodegradable & sustainable masterbatch options and the growing need for safe & hygienic packaging materials in the healthcare and food industries are expected to create market growth opportunities. However, the limited availability of biodegradable masterbatch options is a major challenge for the players operating in this market.

Additionally, the incorporation of antimicrobial solutions into masterbatch formulations and the increasing adoption of tailor-made masterbatch solutions are key trends in the masterbatch market.

Customized colors can vary widely, from vibrant and bold to subtle, and are formulated to meet branding requirements, differentiate products, and create a visual impact. Companies across various industries, such as packaging, automotive, and consumer goods, are using color masterbatches, including pearlescent, metallic, fluorescent, and matte finishes, to add depth and dimension to plastic materials. Masterbatches help achieve customized colors and effects in plastics by incorporating color pigments, additives, and functional compounds into polymer matrices to meet specific design requirements. Hence, the rising demand for plastics with customized colors, the need to differentiate products and enhance consumer appeal, increasing consumer preference for personalized products, and government regulatory requirements for product identification and safety support the growth of this market.

Click here to: Get Free Sample Pages of this Report

Click here to: Get Free Sample Pages of this Report

Plastic products encompass a wide range of essential items, offering convenience, durability, and versatility in numerous applications across various industries. According to The World Counts, around 5 trillion plastic bags were used globally in 2022, and approximately 160,000 plastic bags are used globally every second. Plastic packaging is used for preserving freshness and extending the shelf life of food products; it also helps reduce food waste. Plastic is used in the automotive sector for its light weight and design flexibility. In the construction industry, plastic materials contribute to energy efficiency, insulation, and cost-effectiveness. Masterbatches help produce plastic products to meet specific application requirements by providing coloration, functional properties, and performance enhancements. Hence, the increasing application of plastic products is increasing the demand for masterbatches, driving the growth of this market.

The increasing emphasis on hygiene, health, and safety across various industries is driving the need to incorporate antimicrobial solutions. Antimicrobial solutions are chemical substances designed to restrict the growth of microorganisms, including bacteria, viruses, fungi, and algae, on surfaces. Companies are blending antimicrobial additives into masterbatch formulations during the compounding process to reduce the risk of contamination, infection, and transmission of pathogens in environments, including healthcare facilities, food processing plants, and public spaces. Also, the COVID-19 pandemic has further accelerated this trend as a part of infection control measures. All such factors, along with increasing awareness regarding infectious diseases, increasingly stringent hygiene standards, and consumer demand for safer and cleaner products, are supporting the growth of this market.

Biodegradable and sustainable masterbatches are designed to degrade naturally over time, reducing their environmental impact. These formulations contain environmentally friendly additives or polymers. Biodegradable and sustainable masterbatches include bio-based, compostable, and oxo-degradable masterbatches. Companies are focusing on eco-friendly alternatives to address the environmental concerns related to plastic pollution and resource depletion. For instance, in July 2021, LyondellBasell Industries N.V. (Netherlands) collaborated with Laboratories Sarbec (France) to launch new renewable-based bottles marketed under the CirculenRenew brand. SARBEC Laboratories and LyondellBasell designed PE bottles linked to renewable materials with a carbon footprint reduction of up to 75% compared to fossil-based PE plastics. Such developments, along with growing environmental awareness, stringent government regulations & compliances for single-use plastics, and increasing consumer preference for eco-friendly products, are expected to generate growth opportunities for the stakeholders in this market in the coming years.

Based on product, the masterbatch market is broadly segmented into color, additive, white, black, filler, UV, and other products. In 2025, the color segment is expected to account for the largest share of over 23.0% of the masterbatch market. The large market share of this segment can be attributed to the growing demand for customized colors across various industries, including packaging, the increasing importance of visual appeal in consumer products to attract consumers, the growing need for consistent color branding across product lines, and the increasing need to color code products for easy identification and compliance with safety standards.

However, the UV segment is projected to record the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by the increasing awareness regarding the damaging effects of UV radiation on plastics, government regulations & industry standards mandating UV protection, and the growing demand for UV masterbatch products to enhance the durability and longevity of plastic products exposed to outdoor environments. The companies operating in this market are focused on broadening their product portfolios and catering to the changing demands of users. In March 2025, Ampacet Corporation (U.S.) launched UVBLOCK 1496, a new UV barrier masterbatch for food and industrial packaging, as a sustainable alternative to conventional UV solutions based on benzotriazole additives.

Based on type, the masterbatch market is broadly segmented into biodegradable and non-biodegradable masterbatches. In 2025, the non-biodegradable segment is expected to account for the larger share of the masterbatch market. The large market share of this segment can be attributed to the low costs of non-biodegradable plastics, their high durability & long shelf life, which makes them ideal for applications requiring prolonged use and resistance to environmental factors, and the growing demand for non-biodegradable plastics with performance characteristics in end-use industries including packaging, automotive, and consumer electronics.

However, the biodegradable segment is projected to record the higher growth rate during the forecast period 2025–2032. The growth of this segment is driven by the rising demand for biodegradable masterbatch products as sustainable alternatives to traditional plastics, the increasing development of innovative biodegradable polymers, additives, and processing technologies, and government regulations and policies aimed at reducing single-use plastics and promoting the use of biodegradable materials in packaging applications.

Based on polymer, the masterbatch market is broadly segmented into polyethylene (PE), polyamide (PA), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyurethane (PUR), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), ethylene vinyl acetate (EVA), polyvinylidene fluoride (PVDF), polyether ether ketone (PEEK), acrylonitrile butadiene styrene (ABS), and other polymers. In 2025, the polyethylene (PE) segment is expected to account for the largest share of over 24.0% of the masterbatch market. The large market share of this segment can be attributed to the growing demand for polyethylene masterbatch products in packaging applications such as food packaging, beverage containers, and industrial packaging, their increasing use in the automotive industry for interior and exterior components, and agricultural applications including greenhouse films, and irrigation pipes due to their cost-effectiveness, versatility, barrier properties, flexibility, and durability.

However, the polyethylene terephthalate (PET) segment is projected to record the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by the increasing preference for PET masterbatch products due to their clarity, light weight, recyclability, moisture resistance, ease of processing, and barrier properties, and the increasing demand for PET masterbatch products in medical & pharmaceutical packaging applications, in the textile industry for synthetic fibers and fabrics, and in electronics manufacturing. The companies in this market are focused on broadening their product portfolios, catering to the changing demands of users, and gaining a competitive edge in the market. In November 2024, Sukano AG (Malaysia) partnered with PlastiColors (South Africa) to meet the growing demand for PET packaging in South Africa.

Based on end user, the masterbatch market is broadly segmented into building & construction equipment manufacturers, consumer electronics & appliances manufacturers, automotive manufacturers, textile manufacturers, agricultural equipment manufacturers, aerospace & defense equipment manufacturers, packaging manufacturers, medical device manufacturers, and other end users. In 2025, the packaging manufacturers segment is expected to account for the largest share of over 38.0% of the masterbatch market. The large market share of this segment can be attributed to the growing adoption of masterbatch products among packaging manufacturers to enhance the recyclability, biodegradability, and environmental performance of packaging materials, the growing preference for flexible packaging formats, including pouches and bags, and rapid growth in e-commerce and online retail driving the demand for protective and visually appealing packaging materials.

However, the consumer electronics & appliances manufacturers segment is projected to record the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by electronics & appliances manufacturers’ increasing use of masterbatch additives in the production of plastic components for coloration, surface finishing, texture enhancement, reinforcement, flame retardancy, and UV protection, and technological advancements in 3D printing, smart electronics, and IoT devices.

Based on geography, the masterbatch market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of over 36.0% of the masterbatch market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share can be primarily attributed to the rising automotive production and sales in the region, the rapid growth in e-commerce and online retail, the increasing demand for plastic products and packaging materials, the growing use of masterbatch products in applications such as pipes, cables, fittings, and building materials, and the increasing use of masterbatch additives for coloration, functional enhancements, and performance improvements. The region is also projected to register the highest growth rate of over 7.0% during the forecast period.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the masterbatch market are Ampacet Corporation (U.S.), LyondellBasell Industries N.V. (Netherlands), Cabot Corporation (U.S.), PLASTIKA KRITIS (Greece), Plastiblends (India), Hubron International (U.K.), Tosaf Compounds Ltd. (Israel), Penn Color, Inc. (U.S.), Americhem (U.S.), Clariant International Ltd (Switzerland), RTP Company (U.S.), Gabriel-Chemie GmbH (Austria), Avient Corporation (U.S.), SOLTEX PETRO PRODUCTS LTD. (India), Budin Group (U.S.), Poddar Pigments Limited (India), and Exxon Mobil Corporation (U.S.).

|

Particulars |

Details |

|

Number of Pages |

210 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

5.9% |

|

Market Size (Value) |

$22.8 Billion by 2032 |

|

Segments Covered |

By Product

By Type

By Polymer

By End User

|

|

Countries Covered |

Europe (Germany, U.K., Italy, France, Spain, Russia, Netherlands, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Thailand, Singapore, and Rest of Asia-Pacific), North America (U.S., Canada), Latin America (Brazil, Argentina, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, South Africa, and Rest of the Middle East & Africa) |

|

Key Companies Profiled |

Ampacet Corporation (U.S.), LyondellBasell Industries N.V. (Netherlands), Cabot Corporation (U.S.), PLASTIKA KRITIS (Greece), Plastiblends (India), Hubron International (U.K.), Tosaf Compounds Ltd. (Israel), Penn Color, Inc. (U.S.), Americhem (U.S.), Clariant International Ltd (Switzerland), RTP Company (U.S.), Gabriel-Chemie GmbH (Austria), Avient Corporation (U.S.), SOLTEX PETRO PRODUCTS LTD. (India), Budin Group (U.S.), Poddar Pigments Limited (India), and Exxon Mobil Corporation (U.S.) |

The masterbatch market study focuses on market assessment and opportunity analysis based on the sales of various masterbatch products across different regions, countries, and market segments. This study also includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies.

The masterbatch market is projected to reach $22.8 billion by 2032, at a CAGR of 5.9% during the forecast period.

In 2025, the non-biodegradable segment is expected to account for the larger share of over 24.0% of the masterbatch market. The large market share of this segment can be attributed to the low cost of non-biodegradable plastics, their high durability, and long shelf life, which makes them ideal for applications requiring prolonged use and resistance to environmental factors, and the growing demand for non-biodegradable plastics with performance characteristics across end-use industries including packaging, automotive, and consumer electronics. However, the biodegradable segment is projected to record the higher growth rate.

The polyethylene terephthalate (PET) segment is projected to record the highest growth rate during the forecast period 2025–2032. The growth of this segment is driven by the increasing preference for PET masterbatch products due to their clarity, light weight, recyclability, moisture resistance, ease of processing, and barrier properties, and the increasing demand for PET masterbatch products in medical & pharmaceutical packaging applications, in the textile industry for synthetic fibers and fabrics, and in electronics manufacturing.

The growth of this market is primarily driven by the increasing requirements for functional additives in plastics manufacturing, the rising demand for plastics with customized colors, textures, and properties, and the increasing application of plastic products across various industries. Additionally, the increasing demand for biodegradable & sustainable masterbatch options and the growing need for safe & hygienic packaging materials in the healthcare and food industries are expected to create market growth opportunities.

The key players operating in the masterbatch market are Ampacet Corporation (U.S.), LyondellBasell Industries N.V. (Netherlands), Cabot Corporation (U.S.), PLASTIKA KRITIS (Greece), Plastiblends (India), Hubron International (U.K.), Tosaf Compounds Ltd. (Israel), Penn Color, Inc. (U.S.), Americhem (U.S.), Clariant International Ltd (Switzerland), RTP Company (U.S.), Gabriel-Chemie GmbH (Austria), Avient Corporation (U.S.), SOLTEX PETRO PRODUCTS LTD. (India), Budin Group (U.S.), Poddar Pigments Limited (India), and Exxon Mobil Corporation (U.S.).

Asia-Pacific is expected to offer significant growth opportunities for the vendors in the masterbatch market during the analysis period. Ongoing industrialization across Asia-Pacific countries such as China and India is driving the demand for masterbatch products across various industries, including packaging, automotive, construction, and consumer goods.

Published Date: Oct-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates