Resources

About Us

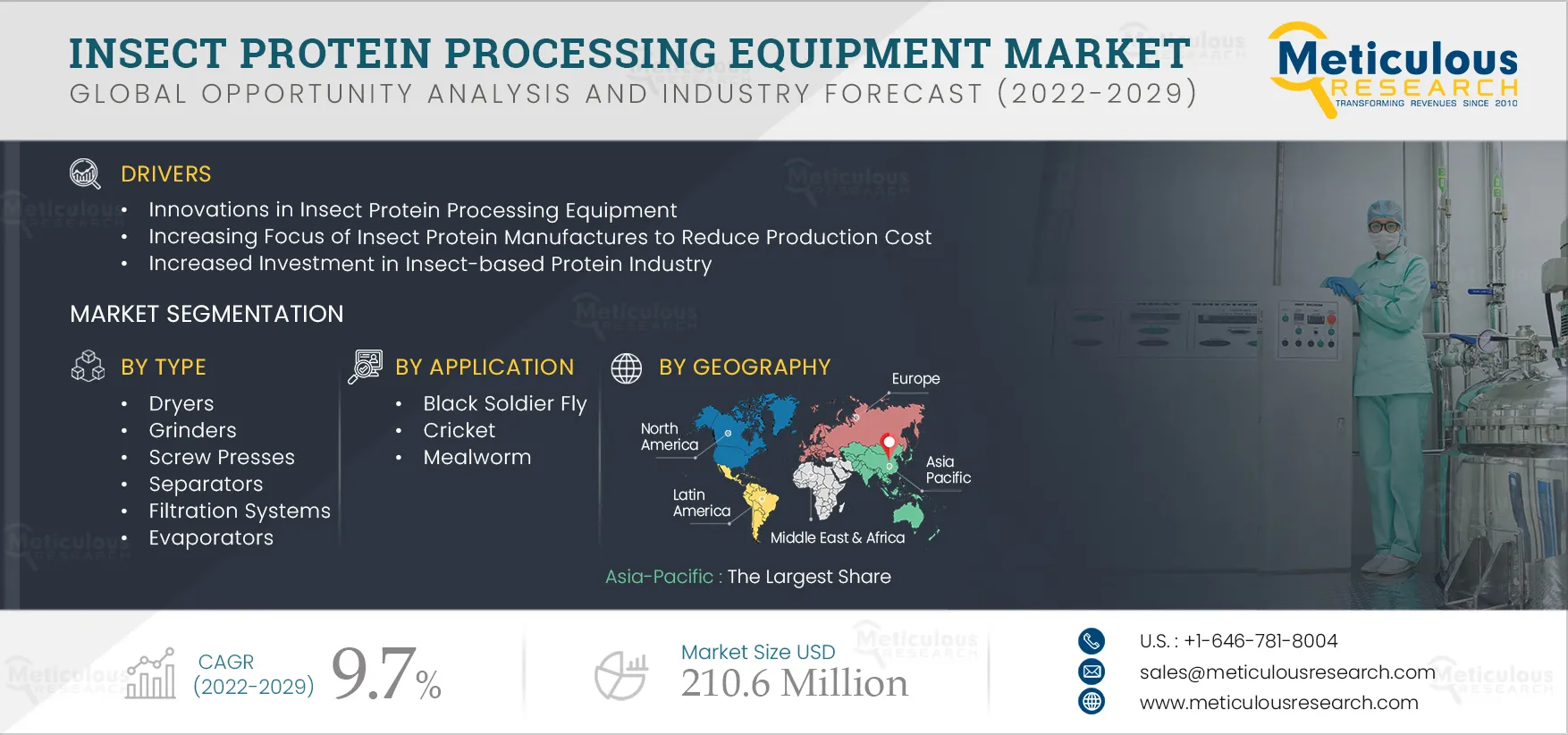

Insect Protein Processing Equipment Market by Type (Dryers, Grinders, Centrifuges), Processing Method (Dry, Wet), Mode of Operation, Production Capacity (Small & Medium Scale, Large Scale), Application (Black Soldier Fly, Cricket) - Global Forecasts to 2029

Report ID: MRFB - 104655 Pages: 200 Aug-2022 Formats*: PDF Category: Food and Beverages Delivery: 24 to 72 Hours Download Free Sample ReportThe Insect Protein Processing Equipment Market is Projected to reach $210.6 Million by 2029, at a CAGR of 9.7% from 2022–2029. In most geographic regions, insect protein is a widely used food source by many indigenous populations. About 1,900 species of insects are eaten worldwide, mainly in developing countries. Insect protein constitutes high-quality food for humans, livestock, poultry, and fish. Insects have a high food conversion rate because they are cold-blooded. Additionally, they emit fewer greenhouse gases than conventional livestock. In some cases, insects can be grown in organic waste-reducing environmental contamination. Therefore, insect protein is a great alternative for conventional production or other animal-based protein sources, either for direct human consumption or indirectly as feedstock

The insect protein processing equipment market is driven by innovations in insect protein processing equipment, the increasing focus of insect protein manufacturers to reduce production costs, increased investments in the insect-based protein industry, and the rising demand for insect protein in the animal feed industry. However, high equipment costs and the risk of allergies due to insect consumption are expected to hinder the growth of this market to a notable extent.

Click here to : Get Free Sample Pages of this Report

The COVID-19 pandemic created numerous global challenges for the food sector, especially meat product manufacturers. The meat products manufacturing industry faced major challenges, such as the risk of continuing production, distribution, transportation, and other supply chain activities; limited workforce; and delays in product development. The rescheduling of private investment financing and public funding initiatives further restricted the food sector’s development. These factors are expected to impact the meat products industry, driving the demand for insect protein.

In 2021, the European Food Safety Authority approved the sale of insects, including migratory locusts (Locusta migratoria) and yellow mealworms, for human consumption (Source: IPIFF). Currently, only a few EU countries use insect-based products. A regionwide approval is projected to drive the demand and sale of insect proteins across Europe, creating immense opportunities for companies operating in the insect protein processing equipment market.

The shutdown of major meatpacking plants due to the COVID-19 pandemic restricted meat production in the U.S., resulting in increased consumer demand. The U.S. Department of Agriculture announced that between March and April 2020, the volume of frozen pork in storage declined by 4%, and slaughter rates dropped by 25%. However, many news sources commented that it is too early to declare a food crisis. Some economists predict that consumers will have significantly fewer options for meat and protein. All these factors and Europe’s recent authorization could create a snowball effect worldwide. As insects contain high quantities of protein, vitamins, and minerals, they could fill the gap in U.S. meat production.

Moreover, the increasing health & wellness trends, the rising awareness among consumers regarding the risk of viral infections, cardiovascular disease, liver disease, bone disorders, and increased risk of certain cancers associated with the long-term use of animal-derived proteins have created traction for sustainable protein sources such as insect proteins that can be cost-effectively reared on waste feed and water. To leverage this traction, many insect protein industry vendors focus on enhancing their production capacities, processes, and end products and raising funds from investors. All these factors provide lucrative growth opportunities for insect protein processing equipment manufacturers.

The covid-19 volatile environment impacted the supply chain of the insect protein processing equipment market due to increased costs and more complex and time-consuming routing of goods. Due to disrupted supply chains and logistic facilities, the global players in this market faced challenges in providing their services and products at their optimum capacity compared to pre-COVID-19. All these factors cumulatively restrained the market from growing. However, a limited workforce directed many companies to invest in automated insect protein processing equipment, which will boost the market at a relatively positive rate for companies offering automated insect protein processing equipment.

The Rising Demand for Insect Protein in the Animal Feed Industry

Developing regions, such as Asia, Africa, and Latin America, are expected to witness exponential human population growth and changes in dietary patterns in tandem with economic growth, leading to a 70% increase in the demand for livestock products by 2050. The prices of livestock products are increasing due to the rising feed costs. At present, the feed cost accounts for 60–70% of the total livestock production costs. Fish and soybean meal are the major protein sources for animal feed. However, these sources compete with food production for humans. Moreover, the availability of fishmeal has become limited due to the over-exploitation of marine resources, causing a rapid increase in the cost of feed ingredients. Hence, the search for sustainable alternatives has led to a growing interest in using insect protein as feed ingredients.

Edible insects have high protein content, and their production has a small footprint. Mass-reared Insect species, such as the black soldier fly, have drawn significant attention due to their ability to feed on different substrates, including organic waste streams. The ability of the black soldier fly to convert organic waste into high-quality nutrients has rapidly spurred the development of black soldier fly-based products, such as protein meal, which is cheaper than fishmeal or soybean meal and can be used as an alternative source of protein in pig, poultry, and fish feeds. Soybean and fishmeal can be replaced with black soldier fly larvae meal. In addition, the black soldier fly can be used as fish feed for Nile tilapia (in different proportions), resulting in similar growth performance and feed conversion.

Therefore, animal feed manufacturers have started incorporating insect protein into their products as an alternative source of protein due to high growth performance and the rising prices of fishmeal and soya meal, the growth drivers of the insect protein processing equipment market.

Based on Type, in 2022, the Dryers Segment is Expected to Account for the Largest Share of the Market

Based on type, the insect protein processing equipment market is segmented into dryers, grinders, screw presses, separators, filtration systems, evaporators, centrifuges, and other equipment. In 2022, the dryers segment is expected to account for the largest share of the insect protein processing equipment market. The large market share of this segment is attributed to its ability to improve process hygiene. Additionally, the growing necessity for customization and replacement for traditional drying techniques are further expected to support the growth of this segment.

Based on Processing Method, in 2022, the Dry Processing Segment is Expected to Account for the Largest Share of the Market

Based on processing method, the insect protein processing equipment market is segmented into dry processing and wet processing. In 2022, the dry processing segment is expected to account for the largest share of the insect protein processing equipment market. The large market share of this segment is attributed to its capacity to obtain high yields, influence product quality, and reduce operational costs.

The Automatic Segment is Projected to Register the Highest CAGR During the Forecast Period

Based on mode of operation, the insect protein processing equipment market is segmented into semi-automatic and automatic. The automatic segment is expected to register the highest CAGR during the forecast period. The fast growth of this segment is mainly attributed to the advantages of automated insect protein processing equipment, such as higher production volumes, reduced labor costs, and improved precision and accuracy.

Based on production capacity, in 2022, the Small & Medium Scale Segment to Account for the Largest Share of the Market

Based on production capacity, the insect protein processing equipment market is segmented into small & medium scale and large scale. In 2022, the small and medium scale segment is expected to account for the largest share of the insect protein processing equipment market. The large market share of this segment is attributed to the rising government support for the development of small-scale processing enterprises, low financial needs, and increased productivity.

Based on Application, in 2022, the Crickets Segment to Account for the Largest Share of the Market

Based on application, the insect protein processing equipment market is segmented into black soldier flies, cricket, mealworms, and other insects. In 2022, the cricket segment is expected to account for the largest share of the insect protein processing equipment market. The large market share of this segment is attributed to factors such as the higher incorporation of crickets in various recipes and products, high nutritional value and easy farming & processing of crickets, and the rising demand for cricket-based food products, such as protein powders, protein bars, and snacks.

In 2022, the Asia-Pacific Region is Expected to Dominate the Global Market

Based on geography, the insect protein processing equipment market is segmented into five major regions: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2022, Asia-Pacific is expected to account for the largest share of the insect protein processing equipment market. The growth of this regional market is attributed to a well-established commercial farming market for edible insects, especially in Thailand, the presence of insect diversity & huge production, positive attitude towards the insect as food & feed, absence of regulatory barriers to insect processing, and the presence of key market players. However, North America is slated to register the fastest growth rate during the forecast period.

Key Players

The report includes a competitive landscape based on an extensive assessment of the key strategic developments by leading market participants in the industry over the past four years. Some of the key players operating in the global insect protein processing equipment market are Alfa Laval AB (Sweden), The Bühler Holding AG (Switzerland), GEA Group Aktiengesellschaft (Germany), Hosokawa Micron B.V. (Netherlands), ANDRITZ Group (Austria), Russell Finex Ltd. (U.K.), Maschinenfabrik Reinartz GmbH & Co. KG (Germany), and The Dupps Company (U.S.).

Scope of the Report:

Insect Protein Processing Equipment Market, by Type

Insect Protein Processing Equipment Market, by Processing Method

Insect Protein Processing Equipment Market, by Mode of Operation

Insect Protein Processing Equipment Market, by Production Capacity

Insect Protein Processing Equipment Market, by Application

Insect Protein Processing Equipment Market, by Region

Key Questions Answered in the Report:

The insect protein processing equipment market is projected to reach $210.6 million by 2029, at a CAGR of 9.7% from 2022 to 2029.

The filtration systems segment is projected to register the highest CAGR during the forecast period and provide significant opportunities for players operating in this market.

The automatic segment is projected to register the highest CAGR during the forecast period and provide significant opportunities for players operating in this market.

The major key players operating in the insect protein processing equipment market are Alfa Laval AB (Sweden), The Bühler Holding AG (Switzerland), GEA Group Aktiengesellschaft (Germany), Hosokawa Micron B.V. (Netherlands), ANDRITZ Group (Austria), Russell Finex Ltd. (U.K.), Maschinenfabrik Reinartz GmbH & Co. KG (Germany), and The Dupps Company (U.S.).

North America is slated to register significant market growth during the forecast period. The growth of this regional market is driven by the growing demand for environment-friendly protein-rich food. Moreover, the increasing familiarity with insects as food, the decreasing food neophobia, altering attitudes towards insects, both in general and as food, and a well-established economy are the key factors contributing to the growth of the insect protein processing equipment market in North America.

Published Date: Feb-2025

Published Date: Jan-2025

Published Date: Jan-2024

Published Date: Jan-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates