Resources

About Us

Industrial Packaging Market Size, Share, Forecast, & Trends Analysis by Type (Secondary, Tertiary), Material (Plastic, Metal, Wood, Paperboard), Sector (Retail & E-Commerce, Food & Beverage, Chemicals, Pharmaceuticals, Automotive & Transportation), and Geography - Global Forecast to 2032

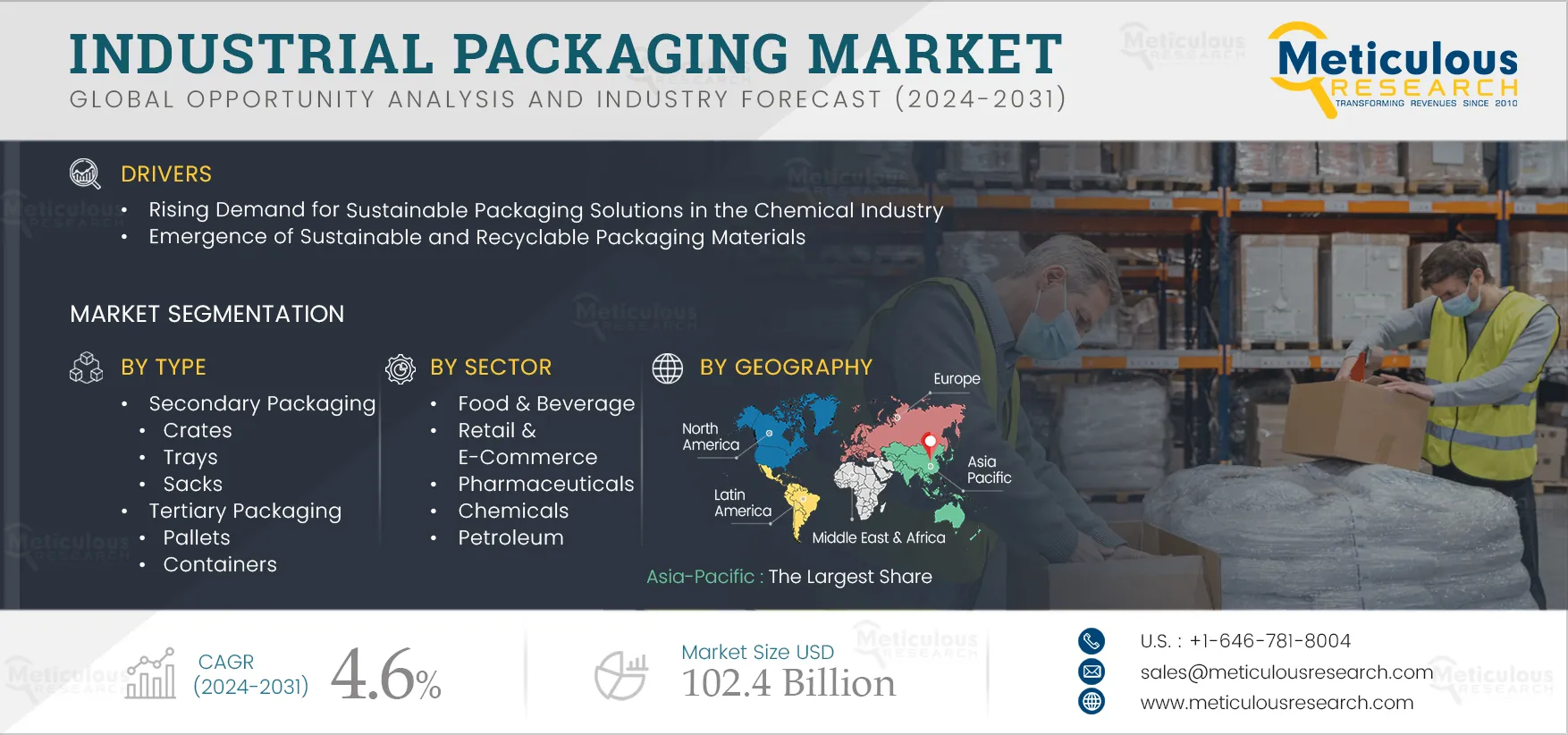

Report ID: MRCHM - 1041144 Pages: 260 Sep-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe Industrial Packaging Market is expected to reach $102.4 billion by 2032, at a CAGR of 4.6% from 2025 to 2032. The growth of the industrial packaging market is driven by the rising demand for sustainable packaging solutions in the chemical industry and the emergence of sustainable and recyclable packaging materials. However, fluctuations in raw material prices may restrain market growth. Furthermore, the increasing focus on packaging design and prototyping services is anticipated to create growth opportunities for market players.

The chemical industry, known for its heavy reliance on packaging to store and transport hazardous and non-hazardous materials, is experiencing a surge in demand for sustainable packaging solutions. Stringent government regulations on waste, emissions, and environmental impact are prompting chemical manufacturers to embrace more sustainable packaging practices. As a result, the chemical industry is setting sustainability targets to reduce carbon footprints and promote environmental responsibility, driving the adoption of packaging materials that are recyclable, reusable, or derived from renewable resources.

Furthermore, rising environmental concerns, organizations' sustainability objectives, and the need for waste reduction and resource conservation are compelling several chemical manufacturing companies to implement strategies to address these factors.

Some of these strategies include:

Click here to: Get Free Sample Pages of this Report

In response to the rising environmental concerns and the need for resource efficiency and waste minimization, numerous packaging solution providers are progressively turning to sustainable and recycled packaging materials. In recent years, governments have been enforcing stricter regulations concerning packaging waste and environmental impact. These policies frequently promote or require the utilization of recycled or sustainable materials in packaging. As a result, companies across various industries are establishing ambitious sustainability objectives to reduce their carbon footprints through the adoption of sustainable and recycled packaging.

Some examples of sustainable and recyclable materials are as follows:

The increasing demand for sustainable and recyclable packaging materials has prompted several industrial packaging providers to launch innovative packaging solutions using recycled materials. For instance, in October 2024, Berry Global Inc. (U.S.) launched its 20 and 25-liter containers containing 35% recycled material. These containers have received UN Approval for the transportation of hazardous goods for five out of the six model liquids in the UN assessment. The addition of these new containers to the company's popular Optimum range will assist companies in achieving their sustainability objectives while meeting consumer demands for more eco-friendly packaging solutions.

In recent years, the use of biodegradable materials in packaging has increased due to the rising global awareness of environmental issues like plastic pollution and climate change. Governments worldwide are enacting stricter regulations and policies to curb plastic waste and promote sustainable packaging solutions. These regulations incentivize the adoption of biodegradable materials while imposing restrictions on single-use plastics. As a result, numerous companies are embracing sustainability as a core value and actively seeking biodegradable packaging options to align with their corporate social responsibility goals.

Moreover, ongoing technological advancements have facilitated the production of biodegradable packaging materials that are both cost-effective and environmentally friendly, further increasing the demand for such packaging solutions. These factors collectively drive the adoption of biodegradable materials for industrial packaging. Additionally, the logistics industry is increasingly utilizing biodegradable material-based packaging for shipping and transporting goods, emphasizing waste reduction and minimizing adverse environmental impacts throughout the supply chain.

The increasing focus on packaging design and prototyping services is prompting packaging suppliers to offer additional support for customers seeking to enhance their packaging. This added service is particularly beneficial for small and medium-sized companies with limited dedicated creative staff. Additionally, with the ongoing technological advancements in industrial packaging, numerous companies are expanding their offerings to include services such as graphic design, package structural design, and container engineering.

Many packaging manufacturers are launching platforms for customized packaging prototypes. For instance, in February 2025, Sappi Europe SA (Belgium), a packaging manufacturer, launched a new digital platform aimed at assisting brand owners and packaging design agencies in creating customized packaging prototypes. Thus, the growing emphasis on packaging design and prototyping services is anticipated to offer significant growth opportunities for market players.

Based on type, the global industrial packaging market is segmented into secondary packaging and tertiary packaging. In 2025, the secondary packaging segment is expected to account for the larger share of 70% of the global industrial packaging market. The large market share of this segment can be attributed to the increasing adoption of secondary packaging among businesses as it facilitates easy handling, stacking, and storage of multiple products. It acts as a protective buffer during shipment, safeguarding the primary packaging. Furthermore, the tamper-evident seals or features incorporated into secondary packaging offer an additional layer of security, ensuring product integrity. Additionally, secondary packaging provides additional space for the inclusion of essential information and labeling, ensuring compliance with regulatory standards and industry regulations.

Moreover, numerous companies are collaborating to offer sustainable secondary packaging solutions. For instance, in August 2022, Mondi plc (U.K.) partnered with Essity AB (Sweden) and Dow Chemical Company (U.S.) to develop recyclable secondary packaging for Essity's feminine care products, incorporating renewable materials and post-consumer recycled content.

Moreover, the secondary packaging segment is projected to register a higher CAGR during the forecast period of 2025 to 2032.

Based on material, the global industrial packaging market is segmented into plastic, wood, metal, paperboard, and other materials. In 2025, the plastic segment is expected to account for the largest share of 51% of the global industrial packaging market. This segment's large market share can be attributed to several factors: the lightweightness of plastic reduces shipping costs and energy consumption during transportation, its versatility allows it to be molded, shaped, and colored into a wide range of designs and forms, enabling custom packaging solutions across various industries, and its compliance with food and pharmaceutical safety regulations ensures industry adherence to strict standards. Additionally, plastic's corrosion resistance makes it an ideal choice for packaging in corrosive environments or for items prone to rusting.

However, the metal segment is projected to register the highest CAGR during the forecast period of 2025 to 2032. The growth of this segment is driven by the increasing adoption of metals such as aluminum and steel in industrial packaging due to their higher durability compared to other materials like paper and plastic. Additionally, the rising utilization of metals such as aluminum and steel is attributed to their excellent barrier properties, effectively protecting products from moisture, air, light, and contaminants. Moreover, metal packaging is designed to seamlessly integrate with automated machinery and processes, thereby facilitating efficient production and packaging lines.

Based on sector, the global industrial packaging market is segmented into food & beverage, retail & E-Commerce, pharmaceuticals, building & construction, chemicals, petroleum, electrical & electronics, automotive & transportation, industrial machinery & equipment, and other sectors. In 2025, the retail & E-Commerce segment is expected to account for the largest share of 24% of the global industrial packaging market. This segment's large market share can be attributed to the growing demand for well-designed secondary packaging in the retail & E-Commerce sector, which enhances brand identity and makes products more recognizable and appealing to consumers. Additionally, the packaging provides an extra layer of protection for products during transportation, handling, and storage.

Moreover, the retail & E-commerce segment is projected to register the highest CAGR during the forecast period of 2025 to 2032.

In 2025, Asia-Pacific is expected to account for the largest share of 46% of the global industrial packaging market. Asia-Pacific's significant market share can be attributed to the presence of prominent players in the region providing industrial packaging solutions for various sectors, the increasing use of packaging in the retail & E-commerce, food & beverage, and pharmaceutical sectors, the rising demand for eco-friendly packaging solutions, the continuous technological innovations enhancing the efficiency and effectiveness of industrial packaging products and services in the region, and the growing adoption of sustainable materials for industrial packaging driven by supportive government policies, regulations, and incentives.

Furthermore, the rising adoption of sustainable packaging materials has prompted numerous packaging solution providers to expand their offerings to meet the growing demand in the region. For instance, in December 2022, Amcor Group GmbH (Switzerland) opened a packaging plant in China, enhancing Amcor's capacity to meet the increasing customer demand across Asia-Pacific. This new facility will specialize in producing flexible packaging solutions for food and personal-care products.

Moreover, the market in Asia-Pacific is projected to register the highest CAGR of 6% during the forecast period of 2025 to 2032.

The report offers a competitive analysis based on an extensive assessment of the leading players' product portfolios and geographic presence and the key growth strategies adopted by them over the past 3–4 years. Some of the key players operating in the industrial packaging market are Greif, Inc. (U.S), Amcor Group GmbH (Switzerland), Berry Global Inc. (a subsidiary of Berry Global Group, Inc.) (U.S.), WestRock Company (U.S.), Mondi plc (U.K.), Crown Holdings, Inc. (U.S.), Smurfit Kappa Group (Ireland), Oji Holdings Corporation (Japan), DS Smith Plc (U.K.), Sonoco Products Company (U.S.), International Paper Company (U.S.), Orora Limited (Australia), Sigma Plastics Group (U.S.), MAUSER Packaging Solutions (U.S.), Global-Pak, Inc. (U.S.), and Ficus Pax Private Limited (India).

In November 2024, Amcor Group GmbH (Switzerland) signed an agreement with NOVA Chemicals Corporation (Canada) to procure mechanically recycled polyethylene resin (rPE) for incorporation into flexible packaging films. Increasing the use of rPE in flexible packaging applications indicates Amcor's dedication to advancing packaging circularity.

In August 2022, BASF SE (Germany) and Nippon Paint Co., Ltd. (China) jointly launched an eco-friendly industrial packaging solution. Leveraging BASF's water-based acrylic dispersion Joncryl High-Performance Barrier (HPB) as the barrier material, this innovative packaging material is intended for use with Nippon Paint's construction dry mortar products.

|

Particulars |

Details |

|

Number of Pages |

260 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

4.6% |

|

Market Size (Value) |

USD 102.4 Billion by 2032 |

|

Segments Covered |

By Type

By Material

By Sector

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Netherlands, Spain, Sweden, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (Saudi Arabia, UAE, Israel, and Rest of the Middle East & Africa) |

|

Key Companies |

Greif, Inc. (U.S), Amcor Group GmbH (Switzerland), Berry Global Inc. (U.S.) (a Subsidiary of Berry Global Group, Inc.), WestRock Company (U.S.), Mondi plc (U.K.), Crown Holdings, Inc. (U.S.), Smurfit Kappa Group (Ireland), Oji Holdings Corporation (Japan), DS Smith Plc (U.K.), Sonoco Products Company (U.S.), International Paper Company (U.S.), Orora Limited (Australia), Sigma Plastics Group (U.S.), MAUSER Packaging Solutions (U.S.), Global-Pak, Inc. (U.S.), and Ficus Pax Private Limited (India). |

This study focuses on market assessment and opportunity analysis by analyzing the sales of industrial packaging solutions across various regions and countries. This study also offers a competitive analysis of the industrial packaging market based on an extensive assessment of the leading players' product portfolios, geographic presence, and key growth strategies.

The global industrial packaging market is projected to reach $102.4 billion by 2032, at a CAGR of 4.6% from 2025 to 2032.

In 2025, the plastic segment is expected to account for the largest share of 51% of the global industrial packaging market. This segment's large market share can be attributed to several factors: the lightweightness of plastic reduces shipping costs and energy consumption during transportation, its versatility allows it to be molded, shaped, and colored into a wide range of designs and forms, enabling custom packaging solutions across various industries, and its compliance with food and pharmaceutical safety regulations ensures industry adherence to strict standards.

The retail & E-commerce segment is projected to register the highest CAGR during the forecast period. The growth of this segment can be attributed to the growing demand for well-designed secondary packaging in the retail & E-Commerce sector, which enhances brand identity and makes products more recognizable and appealing to consumers. Additionally, the packaging provides an extra layer of protection for products during transportation, handling, and storage.

The growth of the industrial packaging market is driven by the rising demand for sustainable packaging solutions in the chemical industry and the emergence of sustainable and recyclable packaging materials. Furthermore, the increasing focus on packaging design and prototyping services is anticipated to create growth opportunities for market players.

The key players operating in the industrial packaging market are Greif, Inc. (U.S), Amcor Group GmbH (Switzerland), Berry Global Inc. (U.S.) (a subsidiary of Berry Global Group, Inc.), WestRock Company (U.S.), Mondi plc (U.K.), Crown Holdings, Inc. (U.S.), Smurfit Kappa Group (Ireland), Oji Holdings Corporation (Japan), DS Smith Plc (U.K.), Sonoco Products Company (U.S.), International Paper Company (U.S.), Orora Limited (Australia), Sigma Plastics Group (U.S.), MAUSER Packaging Solutions (U.S.), Global-Pak, Inc. (U.S.), and Ficus Pax Private Limited (India).

Asia-Pacific is projected to register the highest CAGR of 6% during the forecast period and offer significant growth opportunities for vendors operating in this market.

Published Date: May-2022

Published Date: May-2024

Published Date: May-2024

Published Date: Oct-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates