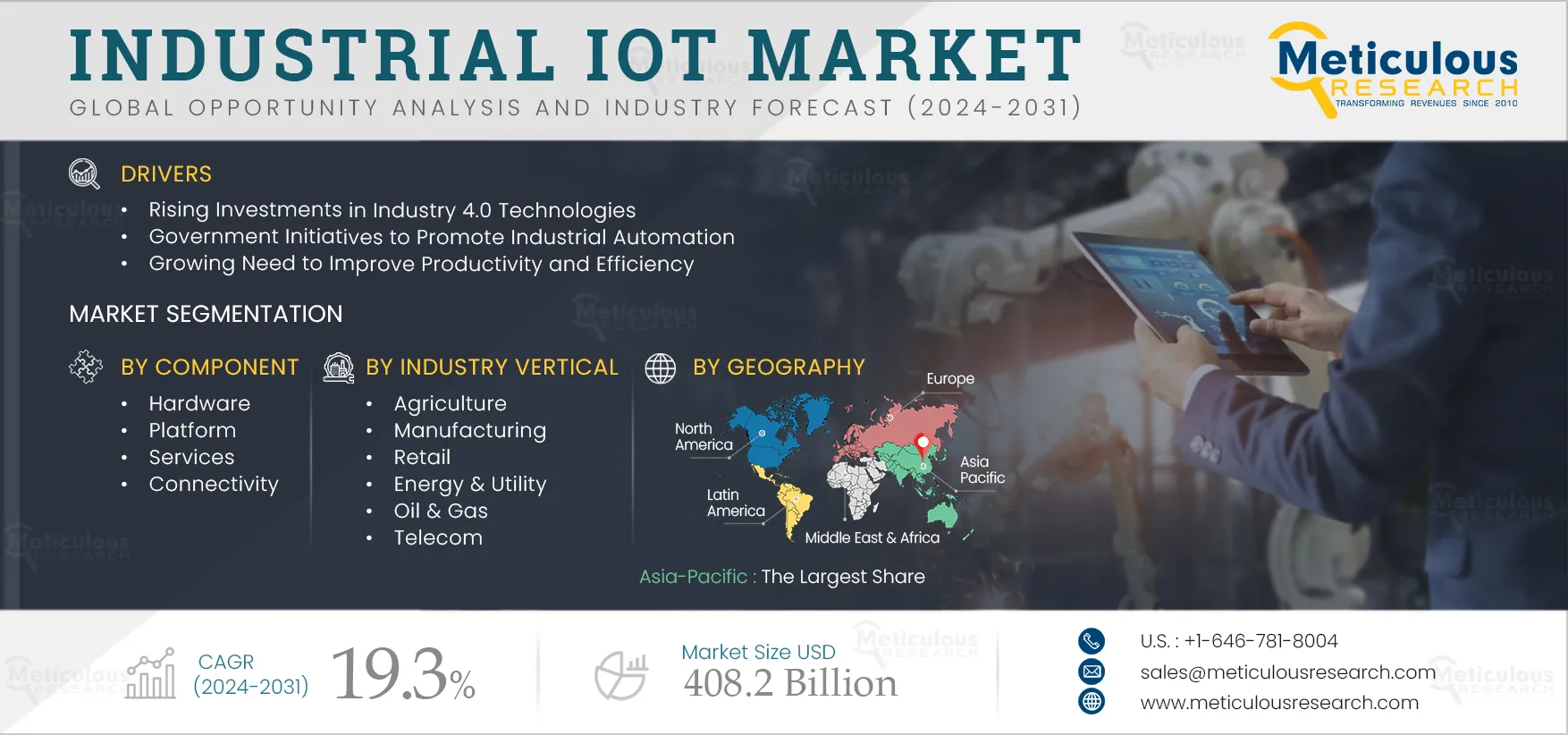

The Industrial IoT Market is expected to reach $408.2 billion by 2031, at a CAGR of 19.3% during the forecast period of 2024–2031. The industrial IoT (IIoT) has been rapidly adopted across several industry verticals, including manufacturing, logistics, oil & gas, transportation, energy/utilities, mining and metals, aviation, and other industrial sectors. The technology provides ample opportunities to incorporate automation, optimization, intelligent manufacturing and smart industry, asset performance management, maintenance, and industrial control applications across organizations. It is also driving organizations towards implementing on-demand service models, focusing on innovative ways of servicing customers, and creating new revenue models to achieve the mature goal of industrial digital transformation. The IIoT market is primarily driven by the increasing usage of cloud computing platforms, consistent technological advancements in semiconductor and electronic devices, and widespread support from various governments for carrying out R&D activities related to IIoT. Moreover, the increasing adoption of industrial IoT for predictive maintenance and the rising number of data centers are expected to provide significant growth opportunities for industrial IoT providers over the forecast period.

Here are the top 10 companies operating in the Industrial IoT Market

IBM functions through five key segments—cognitive solutions, technology services & cloud platforms, global business services, systems, and global financing. The company manufactures and sells hardware & software and delivers numerous hosting and consulting services from mainframe processors to nanotechnology domains. The company has a diverse and vast products and services portfolio covering artificial intelligence, IoT, cloud computing, security, and more.

IBM is the world’s enterprise AI leader and largest cybersecurity enterprise. It provides services to enterprises of all sizes and leaders in diverse industries including financial services, manufacturing, and retail. Some of the subsidiaries of IBM are Red Hat Software, Aspera, Trusteer, FileNet, and Kenexa. The company helps its clients transform their businesses and engage clients and employees in new ways.

Microsoft Corporation is a multinational technology company founded by Paul Allen & Bill Gates and ranked no. 30 in the 2018 Fortune 500 companies list. It is best known for software products such as Internet Explorer, Microsoft Windows OS, Microsoft Office Suite, and Edge Web browsers. Its leading hardware products are the Microsoft Surface lineup of individual touchscreen computers and Xbox videogame consoles. It is specialized in cloud computing, quantum computing, business software, IT professional solutions and services, developer tools, educational software, search engines, advertising, the windows operating system, windows applications & platforms, smartphones, future of work, productivity, artificial intelligence, machine learning, laptops, and virtual reality.

With its subsidiaries and strong distribution network, the company has its presence across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Some of the subsidiaries of Microsoft are Double Fine Productions, GitHub, Semantic Machines, Mojang, Skype, and LinkedIn Corporation.

Intel Corporation

Intel Corporation is engaged in designing and manufacturing products and technologies, such as the cloud. The company operates in the market through six segments, namely, Client Computing Group (CCG), Data Center Group (DCG), Internet of Things Group (IOTG), Non-Volatile Memory Solutions Group (NSG), Intel Security Group (ECG), Programmable Solutions Group (PSG), and All Other and New Technology Group (NTG).

With its subsidiaries and a strong distribution network, the company has its presence in various regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. The major subsidiaries of Intel Corporation are Altera, Mobileye, Nervana Systems, Wind River, eASIC Corporation, and many more.

Cisco Systems Inc.

The company operates in different verticals such as Energy, Education, Financial Services, Government, Healthcare, Manufacturing, Retail, Sports and Entertainment, Cities and Communities, and Transportation. The company offers products and services under various segments like Networking, Internet of Things (IoT), Mobility & Wireless, Security, Collaboration, Data Center, and Cloud. Under the IoT segment, it offers products and services in categories such as IoT Networking, IoT Gateways, Extended Enterprise, IoT Operations Management, IoT Data Management, and IoT Security.

With its subsidiaries and a strong distribution network, the company has its presence in various regions such as North America, Europe, Asia-Pacific, and the Middle East & Africa. Some of the subsidiaries of Cisco Systems, Inc. are Cisco WebEx (U.S.), OpenDNS (U.S.), and BroadSoft (U.S.).

PTC Inc.

PTC Inc. is a software company. It is among the pioneers in digital transformation, and it offers digital solutions comprising IoT and AR technologies, among others. The company offers IIoT solutions for various industry verticals, including aerospace & defence, automotive, electronics, life sciences, and oil & gas. The ThingWorx platform is the most popular platform that hosts IIoT modules and is preferred by many industries.

With its subsidiaries, the company has its offices in North America, Europe, Asia-Pacific, the Middle East & Africa, and Australia. Some subsidiaries of PTC, Inc. are, Kepware, Factora Solutions Corp, and Parametric Korea Co. Ltd. As of 2019, the company had a total headcount of 6,055 employees worldwide, and it has been expanding its presence at a rapid pace over the past few years.

GE Digital

GE Digital is a subsidiary of the global conglomerate corporation General Electrical Company. It is one of the leading global companies offering IIoT solutions and advisory services around operational technology and infrastructure. The company operates through several industry verticals, such as aviation, healthcare, manufacturing, mining, oil & gas, power generation, and transportation. Being one of the promising subsidiaries of General Electric (U.S.), GE Digital’s product offerings range from asset performance management and operations performance management to digital energy and manufacturing systems management. The company offers one of the leading IIoT platforms, Predix, in the IIoT market.

With its subsidiaries and strong distribution network, the company has its presence across North America, South America, Europe, and the rest of the world. Some major subsidiaries of GE Digital are Bit Stew Systems Inc., Wise.io, Inc., and Nurego Inc.

ABB Ltd.

ABB Ltd. is extensively engaged in providing digital transformation solutions and services to various industry verticals. It operates majorly through four business segments, namely Electrification Products, Industrial Automation, Motion Technology, and Robotics and Discrete Automation. IIoT solutions are offered under the Industrial Automation segment of the company, which is also the second-largest revenue-generating segment.

With its subsidiaries and a strong distribution network, the company has its geographic presence across the Americas, Europe, Asia, and the Middle East & Africa. Some of the major subsidiaries of ABB Ltd. are ABB Australia, Power-one, Inc. Tropos Network, among others.

Rockwell Automation, Inc.

Rockwell Automation, Inc. is an industrial automation and information provider that focuses on technology innovation, domain expertise, integrity, and corporate responsibility. The company offers its automation solutions to the automotive, chemical, entertainment, fiber & textiles, food & beverage, household infrastructure, life sciences, mining & metal, and oil & gas, among other industries. The company offers its IIoT platform—ThingWorx, under its Software Components segment. ThingWorx industrial connectivity provides a single solution to collect, aggregate, and securely access industrial operations data. It also provides data access for applications such as Manufacturing Execution Systems (MES), SCADA, IoT, and big data analytics software.

With its subsidiaries and a strong distribution network, the company operates in North America, South America, Europe, Africa, and Asia-Pacific. Some of the major subsidiaries of Rockwell Automation Inc. include Allen-Bradley, Maverick Technologies, MESTECH Services Pvt Ltd, and Automation Control Products.

KUKA AG

KUKA AG is a global supplier of intelligent automation solutions that range from individual components to fully automated systems. The company offers its automation solutions to various industry verticals such as automotive, electronics, healthcare, metal, consumer goods, e-commerce, retail, and energy. The company’s IIoT offering is based on its consulting approach for ‘Industry 4.0’. It offers tailor-made, end-to-end solutions featuring a modular framework comprised of proven standard components. The company provides its IIoT solutions with expertise in web, cloud, and mobile platforms as well.

With its subsidiaries and a strong distribution network, the company operates in North America, South America, Europe, Africa, and Asia-Pacific. Some of the major subsidiaries of KUKA AG are KUKA systems, Swisslog Holding, Reis Robotics, KUKA Roboter Schweiz AG, and KUKA Finance B.V.

Schneider Electric SE

Schneider Electric SE is a leading digital transformation energy management company globally. The company is also engaged in home, building, data center, infrastructure, and industrial automation. The company has a presence in over 100 countries across the globe, and it is considered as one of the global leaders in power management solutions offering medium-voltage, low-voltage, and secure power management solutions and automation systems.

With its subsidiaries and a strong distribution network, the company operates in North America, South America, Europe, Africa, and Asia-Pacific. Some of the major subsidiaries of Schneider Electric SE include Merten, Aveva, Square D by Schneider Electric, and APC by Schneider Electric.

Popular Mentions: Huawei Technologies, Dassault Systems, and Robert Bosch GmbH