Resources

About Us

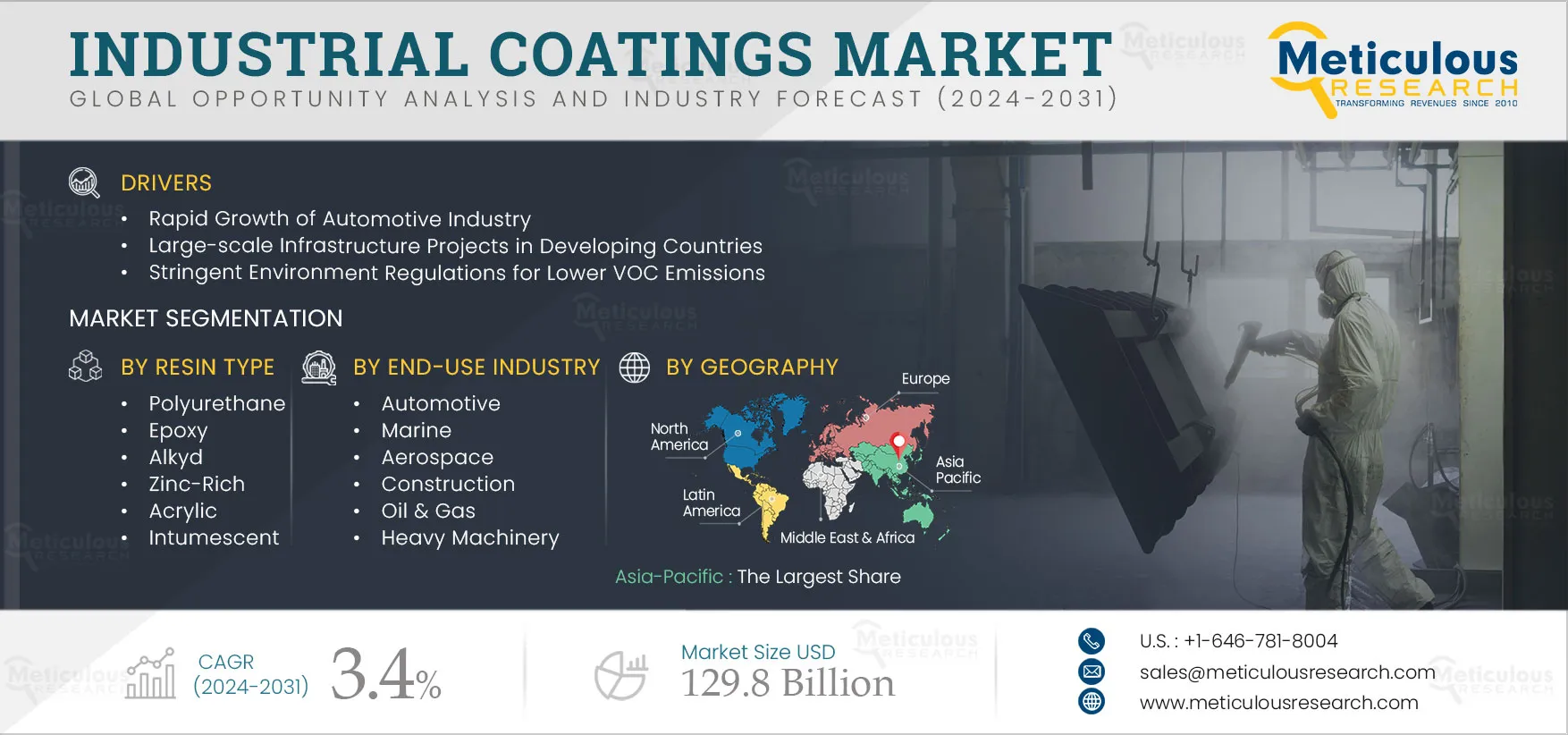

Industrial Coatings Market Size, Share, Forecast, & Trends Analysis by Type (Waterborne, Solvent-borne, Powder), Resin Type (Polyurethane, Epoxy, Alkyd, Acrylic), End-use Industry (Automotive, Aerospace, Oil & Gas, Marine) - Global Forecast to 2032

Report ID: MRCHM - 1041369 Pages: 250 Oct-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThis market's growth is driven by the rapid growth of the automotive industry, large-scale infrastructure projects in developing countries, stringent environmental regulations for lower VOC emissions, and increased demand in the industrial sector to extend product lifespan and reduce maintenance. Furthermore, advancements in polymers and nanotechnology and increasing demand for powder coating in marine applications are expected to generate growth opportunities for the stakeholders in this market.

The industrial sector is prioritizing the reduction of volatile organic compounds (VOCs) released into the atmosphere. As sustainability and environmental responsibility gain importance, there is a growing demand for sustainable materials in industrial coatings. The sector is increasingly favoring low-VOC coatings that are environmentally friendly and safe for workers. Additionally, these sustainable materials comply with specific application requirements, performance standards, and regulatory considerations.

Sustainable materials used in industrial coatings include water-based coatings, bio-based coatings, solvent-reduced formulations, and recycled materials. These coatings are sourced from renewable resources such as plants and agricultural waste. By incorporating recycled materials, the industry can conserve resources, reduce waste, and diminish the demand for virgin materials, thereby lowering carbon emissions. Moreover, the increasing availability of low-VOC solvents facilitates the adoption of sustainable coating formulations. Consequently, manufacturers are integrating sustainable materials into industrial coatings, contributing to a more environmentally friendly future and further supporting market growth.

The automotive industry is experiencing rapid growth in developing countries. Governments globally are acknowledging its significance and are launching various initiatives to support this expansion. For example, in January 2025, India's Ministry of Heavy Industries issued a Gazette Notification extending the tenure of the Production Linked Incentive (PLI) Scheme for automobiles and auto components by one year, with the goal of enhancing the manufacturing of Advanced Automotive Technology (AAT) products. This amendment includes an indicative incentive of USD 259.38 million (INR 25,938 crore).

In the automotive industry, industrial coatings play a vital role in providing protection, aesthetics, and functionality to vehicles. These coatings are applied to various components, including the exterior, interior, and underbody, safeguarding against corrosion, scratches, chips, and environmental factors. Industrial coatings also offer specific functional properties, such as heat resistance, chemical resistance, and UV protection. Numerous companies are supplying industrial coatings for the automotive sector. For example, in September 2025, BASF SE (Germany) launched ChemCycling technology products for the automotive refinish market, aimed at reducing CO2 emissions. Additionally, evolving consumer preferences and trends, such as the increasing popularity of electric vehicles and customization, are further driving the growth of industrial coatings in the automotive industry.

Click here to: Get Free Sample Pages of this Report

Organizations are increasingly focusing on the advancement of polymer and nanotechnology to improve the performance, durability, and functionality of coatings across various industries. The development of high-performance polymers, such as fluoropolymers, polyurethanes, and epoxies, provides enhanced properties like chemical resistance, UV stability, and abrasion resistance for industrial coatings. Additionally, self-healing polymers can repair minor scratches or cracks, extending the lifespan of coatings and reducing maintenance costs.

Organizations are integrating nanoparticles, such as carbon nanotubes and silica nanoparticles, into industrial coatings to enhance properties like scratch resistance, UV stability, and antimicrobial activity. The addition of antimicrobial nanoparticles inhibits the growth of bacteria and fungi, making these coatings suitable for applications in healthcare, food processing, and marine environments. Nanotechnology is also being utilized to develop coatings with self-cleaning properties that repel dirt, water, and contaminants. Furthermore, many polymer and nanotechnology-based coatings are more sustainable than traditional options, helping to reduce environmental impact. These factors present significant growth opportunities for the industrial coatings market during the forecast period.

Based on type, the industrial coatings market is segmented into waterborne coating, solvent-borne coating, powder coating, and other industrial coatings. In 2025, the solvent-borne coating segment is estimated to account for the largest share of the industrial coatings market. The large share of this segment is attributed to the growing use of solvent-based coatings in various industries, including automotive, marine, and aerospace. This is supported by established supply chains for raw materials, additives, and equipment, as well as the rising demand for solvent-based coatings due to their cost-effectiveness compared to water-based alternatives.

Solvent-borne coatings are liquid protective layers composed of organic compounds applied to a material's surface to prevent corrosion. This type of industrial coating utilizes organic solvents to facilitate drying and final film formation. Solvent-borne coatings are generally more resilient than water-borne options during the curing process, allowing for quicker drying times and faster turnaround. These coatings are widely used across industries such as automotive, aerospace, construction, and marine. Furthermore, there are established supply chains for the raw materials, additives, and equipment needed, effectively meeting the large-scale demand in the industrial sector.

Some of the recent developments in this market space are as follows:

Such developments support the growth of the industrial coating market during the forecast period.

In 2025, Asia-Pacific is estimated to account for the largest share of the global industrial coatings market. This large share is primarily attributed to the rapid growth of industrialization, increasing automation in the automotive industry in the region, government initiatives to promote industrial development, booming construction sector in Asian countries, and growing large-scale infrastructure projects in developing countries. Moreover, this region is slated to register the highest CAGR during the forecast period.

The report features a competitive landscape that is based on a comprehensive evaluation of the key strategic developments adopted by market participants over the past three years. The key players profiled in the global industrial coatings market report BASF SE (Germany), Akzo Nobel N.V. (Netherlands), The Sherwin-Williams Company (U.S.), Axalta Coating Systems, LLC (U.S.), Kansai Paint Co., Ltd. (Japan), PPG Industries, Inc. (U.S.), Nippon Paint Holdings Co., Ltd. (Japan), Hempel A/S (Denmark), Teknos Group Oy (Finland), Beckers Group (Germany), Chugoku Marine Paints, Ltd. (Japan), Jotun A/S (Norway), RPM International Inc. (U.S.), Barpimo S.A. (Spain), and DAW SE (Germany).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

3.4% |

|

Market Size (Value) |

USD 129.8 Billion by 2032 |

|

Segments Covered |

By Type

By Resin Type

By End-use Industry

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Australia & New Zealand, Indonesia, Thailand, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, South Africa, Israel, and Rest of Middle East & Africa) |

|

Key Companies |

BASF SE (Germany), Akzo Nobel N.V. (Netherlands), The Sherwin-Williams Company (U.S.), Axalta Coating Systems, LLC (U.S.), Kansai Paint Co., Ltd. (Japan), PPG Industries, Inc. (U.S.), Nippon Paint Holdings Co., Ltd. (Japan), Hempel A/S (Denmark), Teknos Group Oy (Finland), Beckers Group (Germany), Chugoku Marine Paints, Ltd. (Japan), Jotun A/S (Norway), RPM International Inc. (U.S.), Barpimo S.A. (Spain), and DAW SE (Germany) |

The global industrial coatings market size was valued at $101.7 billion in 2024.

The market is projected to grow from $102.8 billion in 2025 to $129.8 billion by 2032.

The industrial coatings market analysis indicates significant growth, reaching $129.8 billion by 2032 at a CAGR of 3.4% from 2025 to 2032.

The key companies operating in this market include BASF SE (Germany), Akzo Nobel N.V. (Netherlands), The Sherwin-Williams Company (U.S.), Axalta Coating Systems, LLC (U.S.), Kansai Paint Co., Ltd. (Japan), PPG Industries, Inc. (U.S.), Nippon Paint Holdings Co., Ltd. (Japan), Hempel A/S (Denmark), Teknos Group Oy (Finland), Beckers Group (Germany), Chugoku Marine Paints, Ltd. (Japan), Jotun A/S (Norway), RPM International Inc. (U.S.), Barpimo S.A. (Spain), and DAW SE (Germany).

A prominent market trend in the industrial coatings market is smart coatings, sustainable materials, and additive manufacturing.

By Type, the solvent-borne coating segment is forecasted to hold the largest market share.

By Resin Type: the epoxy segment is expected to dominate the market.

By End-use Industry, the automotive segment is poised to record the dominant position in the market.

By Geography, Asia-Pacific is slated to register the largest market share.

By region, Asia-Pacific will hold the largest Industrial Coatings Market Share in 2025 and is also expected to witness the fastest growth.

The primary drivers of industrial coatings market growth include the rapid growth of the automotive industry, large-scale infrastructure projects in developing countries, stringent environmental regulations for lower VOC emissions, and increased demand in the industrial sector to extend product lifespan and reduce maintenance.

Published Date: Sep-2024

Published Date: May-2024

Published Date: May-2022

Published Date: Aug-2017

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates