Resources

About Us

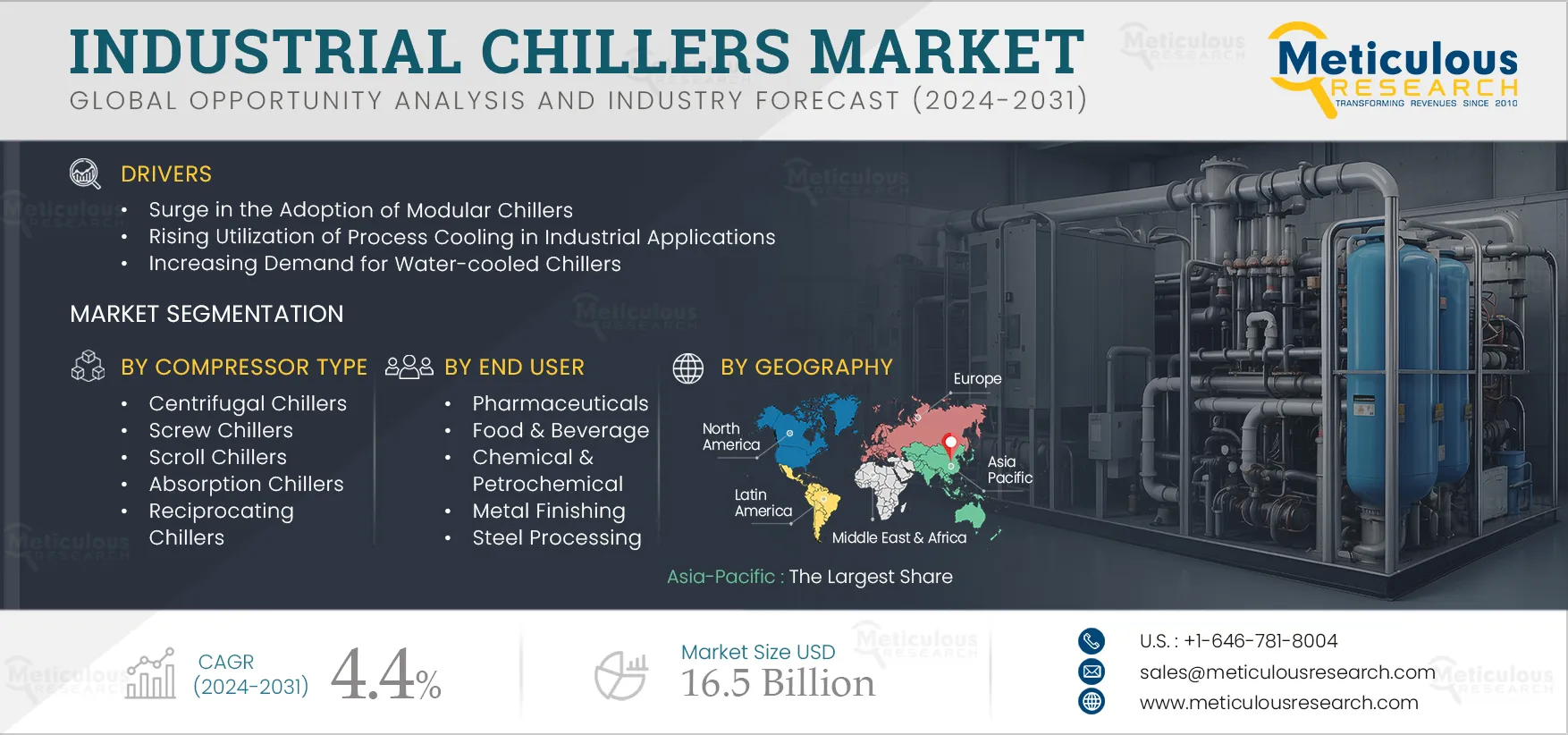

Industrial Chillers Market Size, Share, Forecast, & Trends Analysis by Cooling Type (Air-cooled Chillers, Water-cooled Chillers), Compressor Type (Scroll Chillers, Absorption Chillers), Capacity, End User (Chemical & Petrochemical, Pharmaceuticals) and Geography - Global Forecast to 2032

Report ID: MRSE - 1041332 Pages: 250 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportKey factors driving the growth of this market include the increasing demand for water-cooled chillers, the rising need for process cooling in industrial applications, and a rise in the adoption of modular chillers. Moreover, the rising adoption of chillers and absorption chillers in the chemicals and petrochemicals industries is expected to offer growth opportunities for market participants.

Click here to: Get a Free Sample Copy of this report

There is a rising demand for water-cooled chillers across various industries. These chillers typically consume less energy than air-cooled systems, resulting in significant cost savings, particularly for facilities with high cooling demands. Their capability to handle large thermal loads makes them ideal for sectors such as manufacturing, data centers, and pharmaceuticals, where consistent performance is crucial.

Additionally, water-cooled chillers often have a more compact design, allowing for better space optimization in facilities with limited space. Moreover, these chillers generally utilize eco-friendly refrigerants and help reduce greenhouse gas emissions through effective heat recovery systems. Therefore, the shift towards more efficient, reliable, and environmentally friendly cooling solutions is driving the adoption of water-cooled chillers in the industrial sector, supporting the overall growth of this market.

Such developments are expected to support the growth of this market.

The demand for chillers in the chemicals and petrochemicals industries is experiencing significant growth, driven by the need for precise temperature control and process optimization. Maintaining optimal operating temperatures is essential in these industries to ensure the efficiency of chemical reactions and the quality of final products. Chillers play a vital role in managing heat generated during exothermic reactions. As regulatory frameworks regarding safety and environmental standards become increasingly stringent, industries are compelled to invest in reliable and efficient cooling solutions to enhance operational safety and ensure compliance with these regulations.

Energy efficiency and sustainability are crucial factors driving the growing demand for chillers in the chemical and petrochemical sectors. As companies face increasing pressure to reduce their carbon footprints and meet sustainability goals, investing in energy-efficient chillers has become a strategic priority. Modern chillers equipped with advanced technologies, such as variable speed drives and enhanced heat exchangers, deliver improved performance while minimizing energy consumption and operational costs. This emphasis on energy efficiency not only helps companies comply with environmental regulations but also positively impacts their overall profitability. Therefore, the increasing need for enhanced process efficiency, safety, and sustainability in the chemicals and petrochemical industries is expected to offer growth opportunities for companies operating in the industrial chillers market.

The demand for smart and connected industrial chillers is rising as industries strive for enhanced energy efficiency and sustainability. These innovative chillers leverage IoT technology to enable real-time monitoring and data analytics, facilitating predictive maintenance that reduces downtime and improves operational reliability. By optimizing performance, smart chillers significantly decrease energy consumption and operational costs, helping businesses meet their sustainability objectives and comply with stringent environmental regulations.

Furthermore, their customizable and scalable designs provide tailored solutions for various industrial applications, ensuring maximum efficiency. Additionally, remote management capabilities allow operators to make proactive adjustments, minimizing the need for on-site interventions and enhancing responsiveness. Smart and connected chillers are becoming essential components of modern industrial infrastructure as companies increasingly embrace digital transformation and focus on lowering their carbon footprints. This trend not only drives operational excellence but also reinforces a commitment to a more sustainable future, positioning organizations to succeed in an eco-conscious marketplace.

By cooling type, the industrial chillers market is segmented into water-cooled chillers and air-cooled chillers. In 2025, the water-cooled chillers segment is expected to account for a larger share of 56.0% of the industrial chillers market. The large market share of this segment is primarily attributed to the increasing demand for energy-efficient cooling systems, the growing adoption of water-cooled chillers in the chemicals and petrochemicals industries, and the rising need for water-cooled chillers in large-scale data centers.

Furthermore, the advantages offered by water-cooled chillers—such as high energy efficiency, cost savings, longer lifespan, improved cooling performance, and enhanced temperature control—are key factors contributing to the significant market share of this segment.

However, the air-cooled chillers segment is projected to record the highest CAGR during the forecast period. The increasing adoption of smart and connected air-cooled chillers, along with the rising demand for these chillers in the food & beverage and pharmaceutical industries, is expected to drive the growth of this segment.

Based on compressor type, the industrial chillers market is segmented into centrifugal chillers, screw chillers, scroll chillers, absorption chillers, reciprocating chillers, and other chiller types. In 2025, the scroll chillers segment is expected to account for the largest share of over 58.3% of the industrial chillers market. The large market share of this segment is primarily attributed to the increasing demand for scroll chillers in data centers, the growing need for effective cooling solutions to maintain optimal operational temperatures, and the growing reliance on process cooling across various industries.

However, the absorption chillers segment is projected to record the highest CAGR during the forecast period. The increasing use of absorption chillers in the pharmaceutical industry for precise temperature control and the growing emphasis on energy efficiency are expected to drive the growth of this segment. Additionally, the advantages offered by absorption chillers, including energy efficiency, stable cooling performance, flexibility, and the use of environmentally friendly refrigerants, further contribute to the segment's growth.

Based on capacity, the industrial chillers market is segmented into <50kW, <51-100kW, <101-500kW, <501-1000kW, and>1001kW. In 2025, the <501-1000kW segment is expected to account for the largest share of over 29.1% of the industrial chillers market. The large market share of this segment is attributed to the rising demand for high-capacity chillers and the increasing adoption of these chillers in metal finishing and steel processing applications.

Moreover, the <501-1000 kW segment is projected to record the highest CAGR during the forecast period. The growth of this segment is driven by the benefits offered by industrial chillers in this capacity range, including high cooling capacity, energy efficiency, advanced control systems, and improved process efficiency.

Based on end user, the industrial chillers market is segmented into pharmaceuticals, food & beverage, chemical & petrochemicals, metal finishing, plastic procession, steel processing, medical, and other end users. In 2025, the chemical & petrochemical segment is expected to account for the largest share of over 24.2% of the industrial chillers market. The large market share of this segment is primarily attributed to the growing demand for water-cooled chillers in chemical plants, the increasing use of screw chillers in the chemicals and petrochemicals industries, and the rising adoption of industrial chillers in heat-sensitive processes

Moreover, the chemical & petrochemical segment is projected to record the highest CAGR during the forecast period.

Based on geography, the industrial chillers market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of over 46.5% of the industrial chillers market. Asia-Pacific’s major market share is primarily attributed to the presence of leading industrial chiller companies in this region. Additionally, factors such as rapid industrialization, the growing adoption of modular chillers, the increasing demand for absorption chillers, and the rising need for smart and connected chillers are driving the growth of this market in Asia-Pacific.

Moreover, Asia-Pacific is expected to witness the highest CAGR of 5.5% during the forecast period. The market’s growth in Asia-Pacific is driven by rapid economic growth, particularly in China, South Korea, Japan, and India, along with ongoing infrastructural development in the region. Additionally, supportive government policies, significant industrial growth, and increasing demand for cooling solutions in the manufacturing, pharmaceuticals, and food processing sectors are further fueling the growth of this regional market.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios and geographic presence and the key growth strategies adopted by them over the past three to four years. Some of the prominent companies operating in the industrial chillers market are DAIKIN INDUSTRIES, Ltd.(Japan), Carrier Global Corporation (U.S.), Trane Technologies plc (Ireland), Johnson Controls Inc. (U.S.), Mitsubishi Electric Corporation (Japan), Chillmax Technologies Pvt Ltd. (India), Reynold India Private Limited (India), Drake Refrigeration Inc.(U.S.), Senho Machinery Shenzhen Co. Ltd.(China), Jiangsu Huazhao Refrigeration Equipment CO., Ltd. (China), Friulair S.r.l. (Italy), Atlas Copco Group (Sweden), Kirloskar Chillers Pvt Ltd. (India), Envisys Technologies Private Limited. (India), and SCY Chiller (China).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

4.4% |

|

Market Size (Value) |

$16.5 Billion by 2032 |

|

Segments Covered |

By Cooling Type

By Compressor Type

By Capacity

By End User

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Switzerland, Poland, Netherlands, Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, South Korea, Australia & New Zealand, Indonesia, Rest of Asia-Pacific), Latin America (Brazil, Mexico, Rest of Latin America) and the Middle East & Africa (UAE, Israel, Saudi Arabia, Rest of Middle East & Africa) |

|

Key Companies |

DAIKIN INDUSTRIES, Ltd. (Japan), Carrier Global Corporation (U.S.), Trane Technologies plc (Ireland), Johnson Controls Inc. (U.S.), Mitsubishi Electric Corporation (Japan), Chillmax Technologies Pvt Ltd. (India), Reynold India Private Limited (India), Drake Refrigeration Inc.(U.S.), Senho Machinery Shenzhen Co. Ltd.(China), Jiangsu Huazhao Refrigeration Equipment CO., Ltd. (China), Friulair S.r.l. (Italy), Atlas Copco Group (Sweden), Kirloskar Chillers Pvt Ltd. (India), Envisys Technologies Private Limited. (India), and SCY Chiller (China). |

The industrial chillers market study focuses on market assessment and opportunity analysis based on the sales of industrial chillers across various countries, regions, and market segments. The study includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios and geographic presence and the key growth strategies adopted by them over the past 3–4 years.

The industrial chillers market is projected to reach $16.5 billion by 2032, at a CAGR of 4.4% during the forecast period 2025–2032.

In 2025, the water-cooled chillers segment is expected to account for a larger share of 56.0% of the industrial chillers market. The large market share of this segment is primarily attributed to the increasing demand for energy-efficient cooling systems, the growing adoption of water-cooled chillers in the chemicals and petrochemicals industries, and the rising need for water-cooled chillers in large-scale data centers.

Key factors driving the growth of this market include the increasing demand for water-cooled chillers, the rising need for process cooling in industrial applications, and a rise in the adoption of modular chillers. Moreover, the rising adoption of chillers and absorption chillers in the chemicals and petrochemicals industries is expected to offer growth opportunities for market participants.

The key players in the industrial chillers market include DAIKIN INDUSTRIES, Ltd.(Japan), Carrier Global Corporation (U.S.), Trane Technologies plc (Ireland), Johnson Controls Inc. (U.S.), Mitsubishi Electric Corporation (Japan), Chillmax Technologies Pvt Ltd. (India), Reynold India Private Limited (India), Drake Refrigeration Inc.(U.S.), Senho Machinery Shenzhen Co. Ltd.(China), Jiangsu Huazhao Refrigeration Equipment CO., Ltd. (China), Friulair S.r.l. (Italy), Atlas Copco Group (Sweden), Kirloskar Chillers Pvt Ltd. (India), Envisys Technologies Private Limited. (India), and SCY Chiller (China).

At present, Asia-Pacific dominates the industrial chillers market. Moreover, India, South Korea, and Singapore are expected to witness strong growth in the demand for industrial chillers in the coming years.

Published Date: Nov-2024

Published Date: Jan-2023

Published Date: Jul-2022

Published Date: Jul-2023

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates