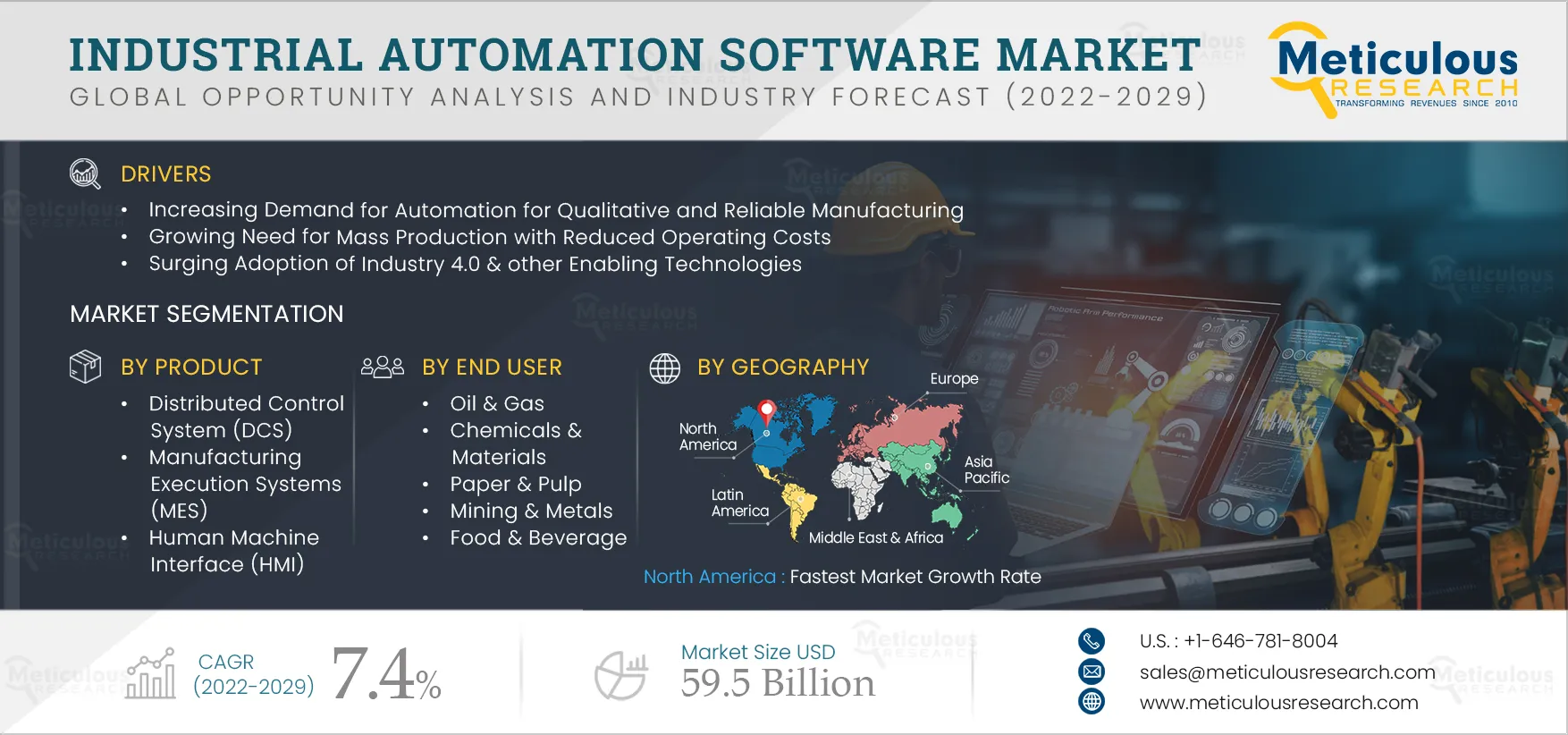

The Industrial Automation Software Market is expected to reach a value of $59.5 billion by 2029, at a CAGR of 7.4% during the forecast period 2022–2029. The global industrial automation software market is expected to reach a value of $59.5 billion by 2029, at a CAGR of 7.4% during the forecast period 2022–2029. An increase in demand for automation for qualitative & reliable manufacturing, the growing need for mass production with reduced operation costs, and the emergence of Industry 4.0 & enabling technologies are the key factors driving the growth of the global industrial automation software market. The emerging automation-driven industries in developing countries provide significant growth opportunities for players operating in this market.

Here are the top 10 companies operating in the Industrial Automation Software Market

Founded in 1890 and headquartered in Missouri, U.S., Emerson Electric Co. is engaged in designing and manufacturing automation products and delivering services for various industrial, commercial, and consumer markets. The company provides smart manufacturing solutions in several categories, including augmented reality products, measurement & instrumentation products, operations management software, automation & control software, valves, actuators & regulators, control and safety systems, welding, assembly and cleaning, and automation services. The company also offers smart manufacturing solutions for various industries, such as life sciences, power generation & transmission, energy, cold chain, and food & water.

The company operates through two business segments: Automation Solutions and Commercial & Residential Solutions. Through its Automation Solutions segment, Emerson Electric provides a broad range of products and integrated solutions, including measurement and analytical instrumentation, industrial valves and equipment, and process control software and systems.

With its subsidiaries and strong distribution network, the company has a geographical presence across the Americas, Europe, and Asia the Middle East & Africa. Some of its subsidiaries are Rosemount Inc. (U.S.), Roxar AS (Norway), Anderson Greenwood Crosby (U.S.), Greenlee (U.S.), Knurr AG (Germany), and Open Systems International, Inc. (U.S.). As of December 2021, the company had a headcount of 86,700 employees globally.

Siemens AG (Germany)

Established in 1847 and headquartered in Munich, Germany, Siemens AG is active globally and focuses on automation and digitalization in the process and manufacturing industries, intelligent infrastructure for buildings and distributed energy systems, and smart mobility solutions for rail and road, and medical technology & digital healthcare services. Siemens’ smart manufacturing solutions create an intelligent production environment through visualization, data analytics, and the ability to share information digitally across the manufacturing ecosystem. The company provides digital twins, cloud solutions and automation solutions for the manufacturing and processing industries.

With its subsidiaries and a strong distribution network, the company has a geographical presence across Europe (excluding Germany), C.I.S., the Middle East & Africa, the Americas, Asia, and Australia. Some of its subsidiaries are Siemens Healthineers AG (Germany), Siemens Canada Limited (Canada), Mentor Graphics (U.S.), Siemens Financial Services (Germany), and Siemens Digital Logistics GmbH (Germany). As of September 2021, the company had a headcount of 303,000 employees globally.

General Electric Company (U.S.)

Founded in 1892 and headquartered in New York, U.S, General Electric Company (GE) is a high-tech industrial company. The company has diversified its business into seven segments, namely Power, Renewable Energy, Healthcare, Aviation, and Transportation. In addition, the company offers edge computing services such as Predix edge.

With its subsidiaries and a strong distribution network, the company has a geographical presence in various regions such as North America, Europe, Asia-Pacific, and the Rest of the World. General Electric has a global presence across 170 countries. Some of its subsidiaries are GE Healthcare (U.S.), GE Aviation (U.S.), GE Digital (U.S.), and GE Capital (U.S.). As of December 2021, the company had a global headcount of approximately 168,000 employees.

Schneider Electric SE (France)

Founded in 1836 and headquartered in Rueil-Malmaison, France, Schneider Electric SE (Schneider) is engaged in manufacturing energy management systems and automation solutions. It operates through two major business segments, Energy Management and Industrial Automation. The Energy Management segment is further segmented as low voltage, medium voltage, and secure voltage. The Industrial Automation business segment includes products and solutions for the process, hybrid, and discrete automation industries.

Schneider’s business includes comprehensive edge control systems and software such as distributed control systems, leading safety systems, machine and process control, and human-machine interface operator panels. The company offers a comprehensive product portfolio for industrial automation and control, low-voltage, building automation, residential & small business, medium-voltage & distribution grid, and critical power applications. The company also provides automation solutions for the food industry through its Industrial Automation segment and software and solutions for the brewery, dairy, baked goods and confectionery, cereal, grains, ingredients, sugar, oil, biofuel, and consumer packaged goods applications.

The company has a geographical presence in about 100 countries across North America, Europe, Asia-Pacific, and the Rest of the World. As of December 2021, the company had approximately 128,000 employees globally.

Honeywell International Inc (U.S.)

Founded in 1885 and headquartered in Delaware, U.S., Honeywell International Inc. (Honeywell) is one of the world’s leading technology manufacturing companies. The company operates through four business segments, Aerospace, Performance Materials & Technologies, and Safety & Productivity Solutions. The Performance Material & Technologies segment includes process technologies and automation solutions, including Honeywell Forge connected solutions. The major products & solutions offered by the company, including the Honeywell Forge solutions, are supported by Honeywell Connected Enterprise, which helps in automating processes to improve efficiency while reducing downtime and safety costs. Honeywell serves the aerospace, construction, chemicals & materials, healthcare & pharmaceuticals, manufacturing, retail, and consumer goods industries.

The company has a geographic reach across the U.S, Europe, and other international regions. As of December 2021, the company had a headcount of approximately 99,000 employees globally.

Rockwell Automation, Inc. (U.S.)

Founded in 1903 and headquartered in Armonk, New York, U.S., Rockwell Automation, Inc. (Rockwell) is engaged in manufacturing industrial automation and information solutions. The company operates through three reporting segments: Intelligent Devices, Software & Control, and Lifecycle Services. The Architecture & Software segment is involved in providing control and information platforms, including controllers, electronic operator interface devices, electronic input/output devices, communication and networking products, and industrial computers. The Control Products & Solutions segment offers services in low and medium-voltage electro-mechanical and electronic motor starters; motor and circuit protection devices; AC/DC variable frequency drives, push buttons, signaling devices, termination and protection devices, relays and timers; and various packaged solutions. The company serves discrete and process industries, such as food & beverage, home & personal care, life sciences, automotive and tire, oil & gas, and mining & metal industries. Siemens AG, ABB Ltd, Schneider Electric SA, Emerson Electric Co., Mitsubishi Electric Corp., and Honeywell International Inc. are some of the company’s major competitors.

The company has a robust geographic reach in more than 100 countries, with a presence in the U.S., Canada, China, Mexico, Italy, the U.K., and Germany, among other countries. As of September 2021, the company had a headcount of approximately 24,500 employees globally.

Founded in 1975 and headquartered in Washington, U.S., Microsoft Corporation is a multinational technology company that provides software products such as Internet Explorer, Microsoft Windows OS, Microsoft Office Suite, and Edge Web browser. The company operates through three business segments, namely Productivity and Business Processes, Intelligent Cloud, and More Personal Computing. The company provides industry-specific cloud solutions on the only platform with intelligent edge-to-cloud technologies with industrial automation software and built-in compliance. he company’s industrial automation software comprises Azure IoT Hub, Azure Sphere, and Microsoft defender for IoT.

The company has a geographical presence across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa through its subsidiaries and a strong distribution network. Some of its subsidiaries are Double Fine Productions, Inc. (U.S.), GitHub, Inc. (U.S.), and LinkedIn Corporation (U.S.). As of 2021, the company had a headcount of 181,000 employees across the globe.

IBM Corporation (U.S.)

Founded in 1911 and headquartered in New York, U.S., IBM Corporation provides cloud computing, artificial intelligence, IoT, IT infrastructure, mobile, digital workplace, and cyber-security solutions for enhancing digital experiences, improving performance and data security, and enabling continuous operations. The company also offers a broad portfolio of middleware for collaboration, predictive analytics, software development, and systems management.

IBM Watson IoT Platform connects devices, ingests data, and transforms that data into meaningful insights using AI, analytics, and blockchain capabilities. The Watson IoT Platform offers the simplicity, scalability, and security to start and grow fast for organizations looking to turn a proof of concept (POC) into a complete production-level solution. The company operates through four business segments: Software, Consulting, Infrastructure, And Financing.

The company has a geographical presence across Asia-Pacific, the Americas, Europe, the Middle East & Africa through its subsidiaries and a strong distribution network. Some of its subsidiaries are Red Hat, Inc. (U.S.), Sentaca (Canada), and BigFix, Inc. (U.S.). As of 2021, the company had a headcount of 282,100 employees across the globe.

Mitsubishi Electric Corporation (Japan)

Founded in 1921 and headquartered in Japan, Mitsubishi Electric Corporation is one of the leading global manufacturers of factory automation products such as programmable logic controllers, variable frequency drives, operator interfaces, motion control systems, computer numerical controls, industrial robots, servo amplifiers and motors, and industrial sewing machines. The company operates through six major segments, namely Energy and Electric Systems, Industrial Automation Systems, Information and Communication Systems, Electronic Devices, Home Appliances, and Others.

The company has a geographical presence across Japan, North America, Asia, Europe, and Others through its subsidiaries and a strong distribution network. Some of its subsidiaries are Mitsubishi Electric Control Panel Corporation (Japan), Mitsubishi Elevator Asia Co., Ltd (Japan), and Mitsubishi Electric Thai Auto-Parts Co., Ltd (Japan). As of 2021, the company had a headcount of 145,653 employees across the globe.

Hitachi, Ltd. (Japan)

Founded in 1910 and headquartered in Japan, Hitachi, Ltd. is a leading provider of industrial automation solutions. The company provides industrial automation solutions through its subsidiary Hitachi Vantara LLC (U.S.). Hitachi develops ground-breaking manufacturing technology and automation solutions to improve business results. The company provides IoT, data analytics, intelligent robotics, and AI-based solutions to build sustainable, cost-effective, and resilient factories.

The company also offers advancements in robotics and AI for driving innovation in warehouse automation and a diverse range of services to identify solutions to the issues currently confronting manufacturing industries, such as optimizing global production chains, accelerating new product development, and handling mega-recalls. The company operates through eight business segments: IT, Energy, Industry, Mobility, Smart Life, Hitachi Construction Machinery, Hitachi Metals, and Others.

The company has a geographical presence across Japan, North America, Europe, ASEAN, India, China, and other countries through its subsidiaries and a strong distribution network. Some of its subsidiaries are Hitachi Solutions East Japan, Ltd. (Japan), Hitachi Solutions West Japan, Ltd. (Japan), Hitachi Solutions Create, Ltd. (Japan), Hitachi Solutions Technology, Ltd. (Japan), and Hitachi Alloy, Ltd. (U.S.). As of 2021, the company had a headcount of 350,864 employees across the globe.