Resources

About Us

High Temperature Filters Market Size, Share, Forecast, & Trends Analysis by Filter Type (Glass Fiber, Ceramic, Metallic, Cartridge), Technology (HEPA/ULPA, Porous Media), Temperature, End Use (Power Generation, Steel, Cement, Waste)—Global Forecast to 2032

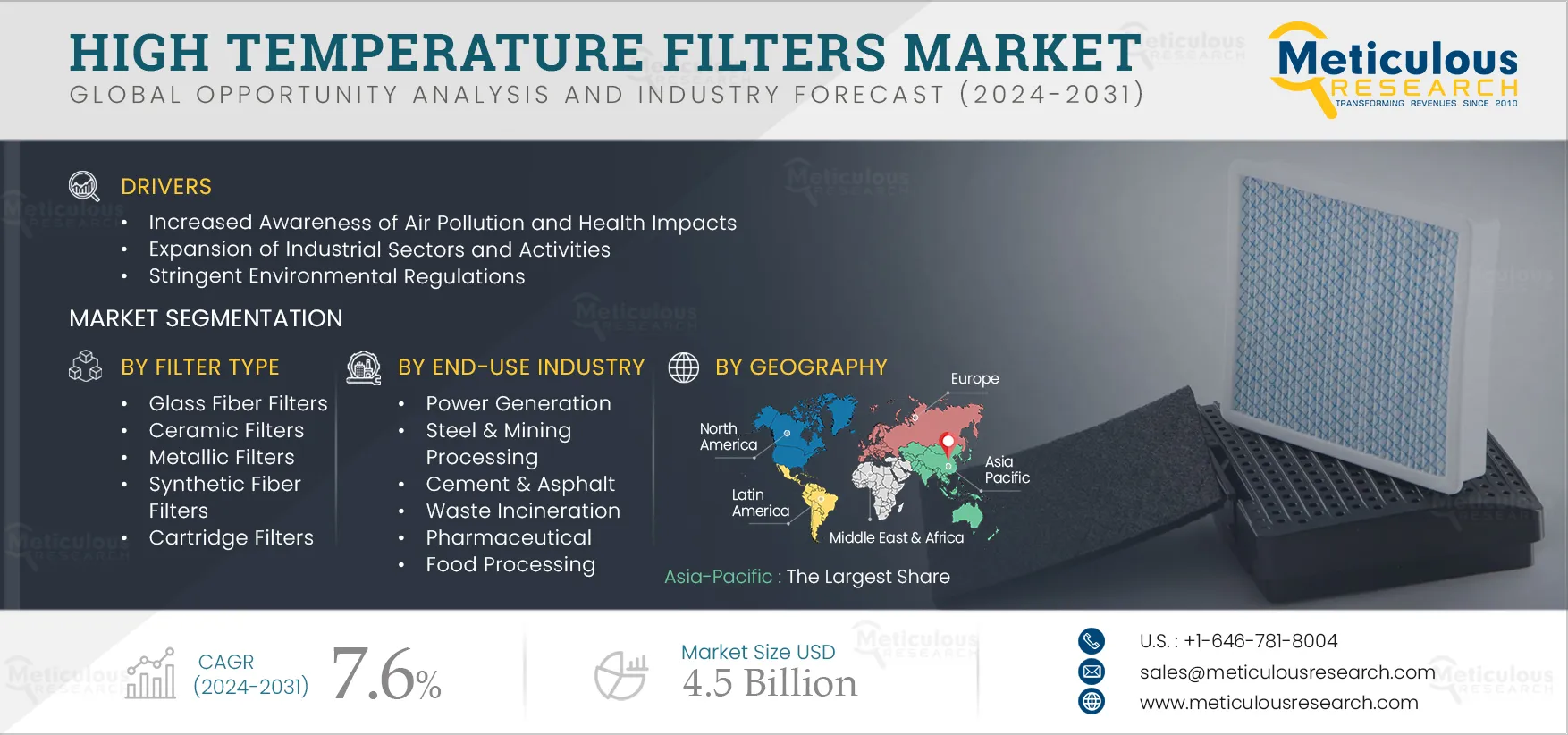

Report ID: MRSE - 1041361 Pages: 180 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of this market can be attributed to several factors, including increased awareness of air pollution and health impacts, the expansion of industrial sectors and activities, and stringent environmental regulations. However, high initial costs may restrain its growth.

Moreover, the growing demand for eco-friendly and sustainable filtration solutions and emerging markets for advanced filtration technologies are anticipated to generate growth opportunities for market stakeholders. However, the ongoing maintenance and upkeep requirements pose a substantial challenge to market growth.

Furthermore, the rising demand for customizable filtration systems represents a prominent trend in the high temperature filters market.

Key Findings High Temperature Filters Market

Click here to: Get Free Sample Pages of this Report

Governments globally are enacting stringent environmental regulations to address air pollution challenges. High concentrations of pollutants, such as sulfur dioxide, nitrogen oxides, particulate matter (PM), and volatile organic compounds (VOCs), significantly impact air quality, contributing to respiratory illnesses and environmental degradation. This situation underscores the need for rigorous control measures. According to the EPA's Air Pollutant Emissions Trends Data, approximately 66 million tons of pollutants were emitted in the United States in 2024, primarily contributing to ozone formation, acid deposition, and visibility impairment.

In response to these challenges, various environmental regulations have been implemented across regions. For example, the U.S. Environmental Protection Agency (EPA) enforces air quality standards under the Clean Air Act, requiring industries to limit hazardous air pollutant emissions and establish national ambient air quality standards (NAAQS) to ensure public health safety. Similarly, the European Union’s Industrial Emissions Directive (IED) aims to prevent and mitigate harmful industrial emissions while promoting techniques that enhance energy and resource efficiency. Larger industrial facilities engaged in specific activities are mandated to utilize Best Available Techniques (BAT) to minimize emissions to air, water, and land.

In the U.S., the National Emission Standards for Hazardous Air Pollutants (NESHAP) regulate the release of hazardous pollutants from industrial sources. As companies strive to meet these standards and avoid significant penalties, the growing necessity to reduce harmful emissions and adhere to environmental regulations is driving the adoption of high-temperature filters across various industries. This trend is expected to significantly contribute to market growth in the coming years.

Air quality is fundamentally connected to the Earth's climate and global ecosystems. Air pollution is defined as the contamination of indoor or outdoor environments by chemical, physical, or biological agents that disrupt the natural atmospheric conditions. Major sources include industrial emissions, vehicle exhaust, chemical vapors, and fossil fuel combustion. These pollutants are associated with serious health issues, including respiratory diseases, cancers, decreased lung function, and asthma, as well as significant environmental impacts, such as acid rain and climate change.

The World Health Organization (WHO) reports that air pollution is responsible for approximately 6.7 million deaths each year, making it a leading cause of preventable mortality. This urgent concern has led to heightened public and governmental awareness regarding the need to address air pollution. Consequently, there has been a marked increase in the adoption of advanced filtration technologies, such as high-temperature filters, which play a critical role in reducing industrial emissions and protecting both public health and the environment.

In sectors such as power generation, high-temperature filters are utilized in gas turbines to capture fine particulates, enhancing plant efficiency and reducing harmful emissions. These filters are specifically engineered to operate under extreme conditions typical of industrial processes, effectively capturing harmful particulate matter, gases, and other pollutants released during operations. Combined with regulatory pressures to mitigate air pollution, these factors are driving increasing demand for high-temperature filters in the coming years.

Regulatory bodies, such as the U.S. Environmental Protection Agency (EPA), impose specific filtration standards based on the emissions and pollutants produced by various industries. Customizable filtration solutions enable companies to comply with these complex regulations while minimizing costs, enhancing operational efficiency, and reducing energy consumption. There is a growing demand for tailored solutions that address specific operational, environmental, and regulatory requirements.

In response, manufacturers of filtration systems are increasingly offering customized solutions adaptable to diverse industrial processes, application environments, and performance needs. Key players, including Donaldson Company, Inc., Parker-Hannifin Corporation, and American Air Filter Company, provide bespoke filter solutions tailored to specific operational environments, featuring variations in filter materials and structures to meet precise contamination control and efficiency needs across sectors such as food and beverage, pharmaceuticals, and heavy industries.

For example, the pharmaceutical industry requires specialized HEPA and ULPA filters for sterile processing in cleanroom environments. The food and beverage sector often demands filters designed to handle bacteria, dust, or steam without compromising product quality. In contrast, the steel and cement industries require robust filters capable of withstanding high temperatures and capturing substantial quantities of particulate matter. These factors are significantly contributing to market growth during the forecast period.

Conventional high-temperature filters often depend on synthetic materials and processes that contribute to environmental degradation and pollution, with manufacturing methods that can be energy-intensive and result in higher carbon emissions. Eco-friendly and sustainable filtration solutions effectively tackle these issues by utilizing materials and practices designed to minimize environmental impact.

These solutions are essential for industries facing increasing regulatory pressures to lower emissions and waste, enabling organizations to achieve sustainability goals while ensuring compliance with environmental regulations. Sustainable filters are crafted from materials that offer high thermal stability and can endure extreme conditions without sacrificing performance. Such materials include bioplastics, natural fibers, ceramics, and recycled metals. For instance, ceramics are renowned for their durability and high-temperature resistance, typically sourced from abundant natural resources like clay, which provides a more sustainable alternative to petroleum-based synthetic materials.

Market players are increasingly focusing on developing filtration systems from recyclable materials and adopting sustainable design practices to reduce waste. Rising regulatory requirements for sustainable practices and an increasing corporate emphasis on social responsibility are creating significant opportunities for innovation and competitive differentiation in the market in the years ahead.

Based on filter type, the high temperature filters market is segmented into glass fiber filters, ceramic filters, metallic filters, synthetic fiber filters, cartridge filters, and other filter types. In 2025, the glass fiber filters segment is estimated to account for the largest share of the high temperature filters market. Glass fiber filters are depth filters made from compressed borosilicate glass fibers, creating an irregular three-dimensional mesh with varying interspaces. They are particularly effective in applications requiring fine filtration and high loading capacity. Additionally, these filters are recognized for their outstanding temperature resistance. Thanks to the inherent properties of borosilicate glass, glass fiber filters can safely filter aggressive solutions, including strong acids and bases. They provide superior filtration efficiency for fine particles while maintaining excellent airflow, making them ideal for environments that demand both durability and effective particle filtration. The significant market share of this segment is largely due to their ability to withstand moderately high temperatures and effectively filter fine particulates, coupled with a high dust-holding capacity. Their growing adoption in industries requiring high-temperature air filtration, such as HVAC, cement, industrial manufacturing, and power generation, further underscores their versatility and performance.

However, the ceramic filters segment is slated to register the highest CAGR during the forecast period. Ceramic filters are ideal for industries like chemical and steel, where temperatures often >1000°C. Features such as their durability in corrosive, acidic, and high-pressure environments, extreme heat resistance, and increasing use for gas filtration in industries including petrochemicals are further supporting the growth of the segment in the coming year.

In 2025, Asia-Pacific is estimated to account for the largest share of the global high temperature filters market. The APAC region, especially countries like China and India, leads the high-temperature filters market, driven by rapid industrialization and a growing manufacturing sector. Key industries such as power generation, cement, and steel processing are expanding significantly. The large market share in Asia-Pacific is largely due to the rising demand for high-efficiency filtration across various industries to effectively manage emissions, along with increasingly stringent government regulations and standards concerning emissions and air quality. Additionally, the expansion of industrial sectors and activities throughout the region further contributes to this growth.

Moreover, Asia-Pacific is also slated to register the highest CAGR during the forecast period. This market's growth is attributed to factors including the expansion of the cement and steel industries, the growing need for high-purity manufacturing environments for the pharmaceutical and chemical sectors, and the growing demand for high-temperature filters to maintain efficiency and reduce emissions.

The report features a competitive landscape derived from a comprehensive evaluation of the key strategic developments undertaken by market participants over the past three years (2021-2025). The key players profiled in the high temperature filters market report are Advanced Filtration Concepts (AFC) (U.S.), Air Filters, Inc. (U.S.), Freudenberg Filtration Technologies GmbH & Co. KG (Germany), American Air Filter Company, Inc. (U.S.), GVS S.p.A. (Italy), Camfil AB (Sweden), Donaldson Company, Inc. (U.S.), Parker-Hannifin Corporation (U.S.), Russell Finex Ltd. (U.K.), Spectrum Filtration Pvt. Ltd. (India), Tri-Mer Corporation (U.S.), Walker Filtration (U.K.), Engineered Filtration Systems (U.S.), Deltrian International S.A. (Belgium), Dyna Filters Pvt. Ltd. (India), Pall Corporation (U.S.), and MANN+HUMMEL International GmbH & Co. KG (Germany).

|

Particulars |

Details |

|

Number of Pages |

180 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

7.6% |

|

Market Size (Value) |

USD 4.5 Billion by 2032 |

|

Segments Covered |

By Filter Type

By Technology

By Temperature Range

By End-use Industry

|

|

Countries Covered |

Europe (Germany, U.K., Italy, France, Spain, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, and Rest of Asia-Pacific), North America (U.S., Canada), Latin America, and the Middle East & Africa |

|

Key Companies |

Advanced Filtration Concepts (AFC) (U.S.), Air Filters, Inc. (U.S.), Freudenberg Filtration Technologies GmbH & Co. KG (Germany), American Air Filter Company, Inc. (U.S.), GVS S.p.A. (Italy), Camfil AB (Sweden), Donaldson Company, Inc. (U.S.), Parker-Hannifin Corporation (U.S.), Russell Finex Ltd. (U.K.), Spectrum Filtration Pvt. Ltd. (India), Tri-Mer Corporation (U.S.), Walker Filtration (U.K.), Engineered Filtration Systems (U.S.), Deltrian International S.A. (Belgium), Dyna Filters Pvt. Ltd. (India), Pall Corporation (U.S.), and MANN+HUMMEL International GmbH & Co. KG (Germany) |

The global high temperature filters market size was valued at $2.6 billion in 2024.

The market is projected to grow from $2.7 billion in 2025 to $4.5 billion by 2032.

The high-temperature filters market analysis indicates significant growth, reaching $4.5 billion by 2032 at a CAGR of 7.6% from 2025 to 2032.

The key companies operating in this market include Advanced Filtration Concepts (AFC) (U.S.), Air Filters, Inc. (U.S.), Freudenberg Filtration Technologies GmbH & Co. KG (Germany), American Air Filter Company, Inc. (U.S.), GVS S.p.A. (Italy), Camfil AB (Sweden), Donaldson Company, Inc. (U.S.), Parker-Hannifin Corporation (U.S.), Russell Finex Ltd. (U.K.), Spectrum Filtration Pvt. Ltd. (India), Tri-Mer Corporation (U.S.), Walker Filtration (U.K.), Engineered Filtration Systems (U.S.), Deltrian International S.A. (Belgium), Dyna Filters Pvt. Ltd. (India), Pall Corporation (U.S.), and MANN+HUMMEL International GmbH & Co. KG (Germany).

A prominent market trend in high temperature filters is the increasing demand for customizable filtration systems.

By filter type, the glass fiber filter segment is forecasted to hold the largest market share.

By technology, the bag filters segment is expected to dominate the market.

By temperature range, the 400°C–1000°C segment is poised to dominate the market.

By end-use industry, the power generation segment is poised to record the dominant position in the market.

By geography, the Asia-Pacific region is slated to register the largest market share.

By region, Asia-Pacific held the largest market share in 2025 for high-temperature filters, driven by rapid industrialization, a growing manufacturing sector, and the expansion of industries such as power generation, cement, and steel processing.

The primary drivers of the high temperature filters market growth include increased awareness of air pollution and its health impacts, expansion of industrial sectors and activities, and stringent environmental regulations.

Published Date: Nov-2024

Published Date: Oct-2024

Published Date: Jan-2024

Published Date: Sep-2020

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates