Resources

About Us

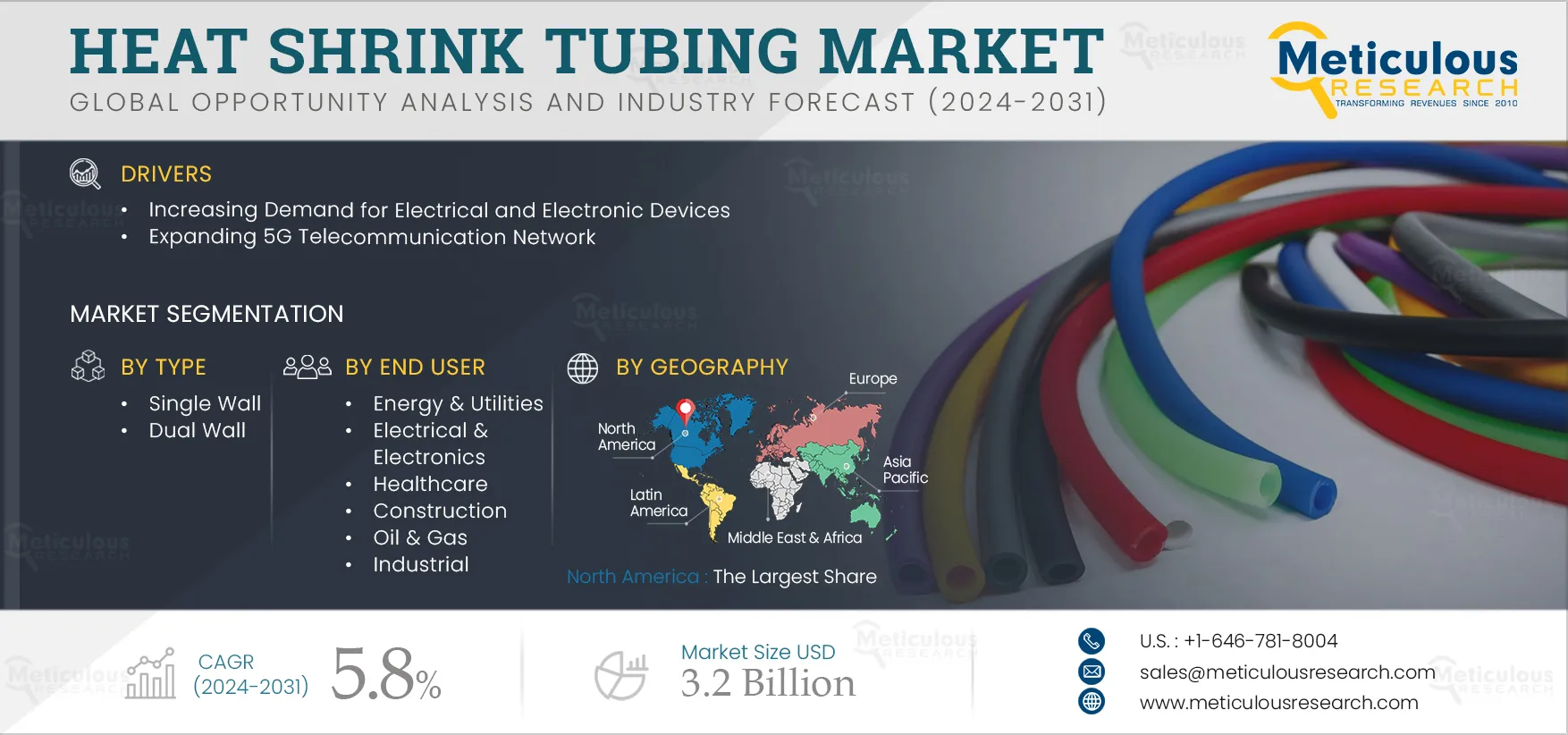

Heat Shrink Tubing Market by Type (Single Wall, Dual Wall), Voltage (Low, Medium), Material (Polyolefin, PVC), Shrink Ratio, End User (Electrical & Electronics, Automotive & Transportation), Geography - Global Forecast to 2032

Report ID: MRSE - 1041371 Pages: 250 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportKey factors driving the growth of this market include the rising demand for electrical and electronic devices and the expansion of the 5G telecommunications network. Furthermore, the increasing use of automotive electronics and the growing need for medical devices are anticipated to offer significant opportunities for market players.

Rising Demand for Electrical and Electronic Devices

Advancements in technology and the growing reliance on digital solutions are driving the demand for electrical and electronic devices. Key industries such as automotive, telecommunications, and consumer electronics are expanding rapidly and innovating new products.

This rising demand for electrical and electronic devices significantly impacts the adoption of heat shrink tubing, as it enhances the reliability and safety of these devices. As electronic devices become more complex, the need for effective insulation and protection for wires, connectors, and components increases. Heat shrink tubing offers essential features such as electrical insulation, abrasion resistance, and moisture protection.

Manufacturers are increasingly launching heat shrink tubing solutions to enhance the performance and durability of their products. For instance, in April 2024, TE Connectivity Corporation (Switzerland), a leader in connectivity and electronic components, launched its new EV Single Wall (EVSW) tubing specifically designed for high-voltage applications, providing safe insulation and protection for conductive components and cables. Such developments contribute to the growing demand for heat shrink tubing in electrical and electronic devices.

The expansion of 5G telecommunications networks is a transformative trend reshaping various sectors and driving significant demand for related technologies and solutions. This growth increases the need for heat shrink tubing to support the installation of base stations, antennas, and other infrastructure components that require reliable insulation and protection.

Additionally, 5G technology utilizes smaller and more compact components, making heat shrink tubing ideal for tight packaging and insulation. This feature facilitates better space management within devices and installations.

Furthermore, the increasing adoption of IoT devices that depend on 5G connectivity drives the demand for reliable insulation and protection for various sensors and communication devices, further driving the need for heat shrink tubing. The telecommunications industry also faces stringent safety and performance regulations, prompting companies to use heat shrink tubing to ensure reliable insulation and protection for wiring and connections.

Moreover, government initiatives aimed at improving connectivity in both urban and rural areas are driving the demand for materials needed for infrastructure development, including heat shrink solutions. Therefore, the expansion of 5G networks is expected to significantly boost the demand for heat shrink tubing during the forecast period.

Click here to: Get Free Sample Pages of this Report

The growth of the healthcare sector is driving the demand for medical devices, including diagnostic equipment, ventilators, and personal protective equipment (PPE). Technological advancements are leading to the development of more sophisticated medical devices, such as wearable health monitors, telemedicine tools, and robotic surgical systems. As the demand for these devices increases, so does the need for heat shrink tubing to insulate and protect wires, cables, and components within them, ensuring reliability and safety.

Heat shrink tubing enhances insulation and protection for health monitors and medical devices, shielding them from moisture, dust, and chemicals. Additionally, the adoption of advanced manufacturing technologies in the medical device sector is boosting the demand for heat shrink tubing, as it helps enhance device durability, reduce maintenance costs, and extend its lifespan.

Many heat shrink tubing manufacturers are partnering with medical device OEMs to provide tailored solutions. For instance, in January 2025, Cobalt Polymers, a U.S.-based manufacturer of heat shrink tubing for the medical device industry, entered into a distribution agreement with HnG Medical Incorporated (Canada). This partnership aims to distribute Cobalt's tubing products in Asia, allowing the company to better serve its OEM customers with local representation and access to tubing samples and inventory. Such developments are expected to significantly boost the demand for heat shrink tubing in medical devices in the coming years.

Based on type, the global heat shrink tubing market is segmented into single wall and dual wall. In 2025, the dual wall segment is estimated to account for the largest share of the global heat shrink tubing market. The large market share of this segment is attributed to the increasing adoption of dual-wall heat shrink tubing across various industries for insulation and protection, the rising use of dual-wall tubing for a wide range of applications, including electrical insulation, strain relief, and protection for wires & connectors, and strict industry standards for electrical insulation and environmental resistance.

Dual wall tubing consists of two layers: an outer layer made from high-performance thermoplastic polyolefin and an inner layer containing a heat-activated adhesive. When heat is applied, the outer layer shrinks tightly around the substrate while the inner adhesive layer melts to create a strong bond. This design provides effective electrical insulation and mechanical protection against abrasion, impacts, and moisture, enhancing sealing capabilities. Dual wall tubing is versatile and easy to install, requiring only heat for application. It finds use across various industries, including automotive, aerospace, and telecommunications.

In 2025, North America is estimated to account for the largest share of the global heat shrink tubing market. North America’s significant market share can be attributed to significant growth in the electronics and electrical industries in the region, ongoing developments in the automotive sector, and the expanding 5G telecommunications network.

However, the market in Asia-Pacific is projected to register the highest CAGR during the forecast period. The growth of this regional market is driven by factors such as rapid industrialization in countries like China, India, and Vietnam, an expanding consumer electronics market, and increasing demand for heat shrink tubing in key sectors, including electronics and automotive.

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by leading market participants over the past three years (2021-2025).

The key players profiled in the global heat shrink tubing market report ABB Ltd (Switzerland), TE Connectivity Corporation (Switzerland), Sumitomo Electric Industries, Ltd. (Japan), 3M Company (U.S.), JIANGSU DASHENG HEAT SHRINKABLE MATERIAL CO., LTD. (China), Panduit Corp. (U.S.), Thermosleeve USA (U.S.), Techflex, Inc. (U.S.), Huizhou Guanghai Electronic Insulation Materials Co., Ltd. (China), Shenzhen Woer Heat - Shrinkable Material Co., Ltd. (China), HellermannTyton (A Part of Aptiv PLC) (U.K), Alpha Wire ( A part of Belden Inc.) (U.S.), and Zeus Industrial Products, Inc. (U.S.).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

5.8% |

|

Market Size (Value) |

USD 3.2 Billion by 2032 |

|

Segments Covered |

By Type

By Voltage

By Material

By Shrink Ratio

By End User

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, Sweden, Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Singapore, Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, Israel, Rest of Middle East & Africa) |

|

Key Companies |

ABB Ltd (Switzerland), TE Connectivity Corporation (Switzerland), Sumitomo Electric Industries, Ltd. (Japan), 3M Company (U.S.), JIANGSU DASHENG HEAT SHRINKABLE MATERIAL CO., LTD. (China), Panduit Corp. (U.S.), Thermosleeve USA (U.S.), Techflex, Inc. (U.S.), Huizhou Guanghai Electronic Insulation Materials Co., Ltd. (China), Shenzhen Woer Heat - Shrinkable Material Co., Ltd. (China), HellermannTyton (A Part of Aptiv PLC) (U.K), Alpha Wire ( A part of Belden Inc.) (U.S.), and Zeus Industrial Products, Inc. (U.S.). |

The global heat shrink tubing market size was valued at $2.1 billion in 2024.

The market is projected to grow from $2.2 billion in 2025 to $3.2 billion by 2032.

The heat shrink tubing market analysis indicates substantial growth, with projections indicating that the market will reach $3.2 billion by 2032 at a compound annual growth rate (CAGR) of 5.8% from 2025 to 2032.

The key companies operating in this market include ABB Ltd (Switzerland), TE Connectivity Corporation (Switzerland), Sumitomo Electric Industries, Ltd. (Japan), 3M Company (U.S.), JIANGSU DASHENG HEAT SHRINKABLE MATERIAL CO., LTD. (China), Panduit Corp. (U.S.), Thermosleeve USA (U.S.), Techflex, Inc.(U.S.), Huizhou Guanghai Electronic Insulation Materials Co., Ltd. (China), Shenzhen Woer Heat - Shrinkable Material Co., Ltd. (China), HellermannTyton (A Part of Aptiv PLC) (U.K), Alpha Wire ( A part of Belden Inc.) (U.S.), and Zeus Industrial Products, Inc.(U.S.).

A prominent market trend in heat shrink tubing is the integration of sensors and monitoring capabilities in hot shrink tubing and increasing emphasis on flame-resistant hot shrink tubing.

By Type, the dual wall segment is forecasted to hold the largest market share during 2025-2032.

By Voltage, the low segment is expected to dominate the market during 2025-2032.

By Material, the Polyolefin segment is expected to dominate the market during 2025-2032.

By Shrink Ratio, the 2:1 segment is expected to dominate the market during 2025-2032.

By End User, the electrical & electronics segment is poised to record the dominant position in the market during 2025-2032.

By Geography, the North America segment is slated to register the largest market share during 2025-2032.

By region, North America holds the largest heat shrink tubing market share in 2025. However, the market in Asia-Pacific is expected to register the fastest growth rate during the forecast period. The growth of this regional market is driven by factors such as rapid industrialization in countries like China, India, and Vietnam, an expanding consumer electronics market, and increasing demand for heat shrink tubing in key sectors, including electronics and automotive.

Key factors driving the growth of this market include the rising demand for electrical and electronic devices and the expansion of the 5G telecommunications network.

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates