Resources

About Us

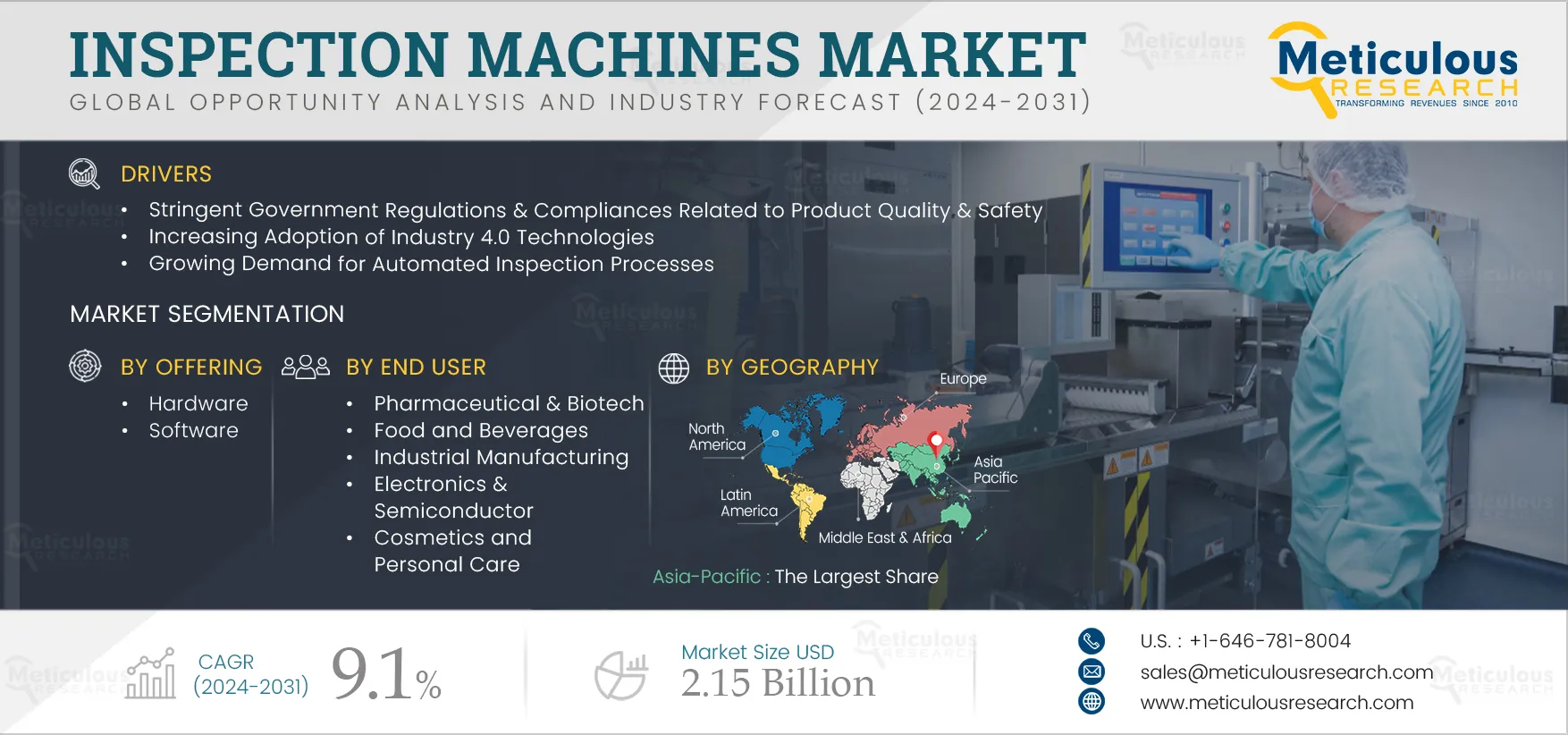

Inspection Machines Market Size, Share, Forecast, & Trends Analysis by Offering (Hardware, Software), Automation Mode (Automatic Inspection, Semi-automatic Inspection, Manual Inspection), End User (Pharmaceutical and Biotech, Food and Beverages), and Geography - Global Forecast to 2031

Report ID: MRSE - 10450 Pages: 227 May-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 2 to 4 Hours Download Free Sample ReportThe Inspection Machines Market is expected to reach $2.15 billion by 2031, at a CAGR of 9.1% from 2024 to 2031. The growth of this market can be attributed to stringent government regulations & compliances related to product quality & safety, the increasing adoption of Industry 4.0 technologies, and the growing demand for automated inspection processes. Moreover, technological advancements in inspection machines and the increasing outsourcing of manufacturing operations in emerging economies are expected to offer growth opportunities for the players operating in this market.

Industry 4.0 leverages advanced digital technologies such as the Internet of Things (IoT), robotics, cloud computing, Artificial Intelligence (AI), and big data analytics to enhance traditional manufacturing operations. It helps create smart, interconnected systems that enable automation, data exchange, and real-time insights. The adoption of Industry 4.0 technologies enables the development of intelligent inspection machines equipped with machine vision, AI, and IoT connectivity for real-time quality control and defect detection. IoT technology helps connect machines, devices, and sensors to collect and exchange data for enhanced automation and decision-making. AI enables machines to learn from data, optimize processes, and perform complex tasks autonomously. Robotics and automated systems help streamline production, improve efficiency, and reduce human intervention. These technologies enable advanced inspection capabilities, including automated defect detection, predictive maintenance scheduling, and real-time data analysis, and help enhance product quality and compliance in industries including manufacturing, healthcare, and automotive.

Market players are focused on integrating advanced technologies to enhance efficiency, accuracy, and versatility in inspection processes across various industries, including electronics & semiconductors. For instance, in June 2022, Dobot (China) launched CR3L, an ultra-long cobot with a reach of 1700 mm, to perform various tasks such as loading and unloading, sorting, and wide-range inspection of small parts in consumer electronics and semiconductor industries. Such developments, coupled with the accelerated shift toward smart manufacturing, increasing demand for advanced inspection technologies, and technological advancements in machine vision and AI, are driving the growth of the inspection machines market.

Click here to: Get Free Sample Pages of this Report

Several industries, including manufacturing, logistics, healthcare, and food processing, are leveraging automation to streamline operations, improve efficiency, and enhance overall productivity. Automated inspection processes involve the use of advanced technologies, including machine vision, robotics, and AI, to perform quality checks and detect defects with minimal human intervention. These systems are employed to ensure the quality and integrity of components and assemblies. Automated inspection processes help identify flaws early in the production process, reducing rework and ensuring compliance with strict industry standards. In industries such as automotive manufacturing, these systems are used for dimensional measurement, surface defect detection, and assembly verification. In the electronics industry, automated inspection processes help ensure PCB (Printed Circuit Board) quality and component placement accuracy. In the pharmaceutical and food & beverage industries, it helps detect contaminants, ensuring product integrity and compliance with regulatory standards.

The companies operating in this market are focusing on partnerships to develop advanced inspection technologies capable of performing complex inspections rapidly and accurately to improve production efficiency, reduce operational costs, and enhance product quality. For instance, in November 2023, GMV Innovating Solutions S.L. (Spain) partnered with ANYbotics AG (Switzerland) to offer high-level availability, reliability, and efficiency in automated inspections with autonomous robots. The partnership is aimed at automating the way companies manage their inspection operations and providing improved effectiveness and optimized resource utilization in industrial environments. Such developments, coupled with the shift toward smart manufacturing and automation, are driving the growth of the inspection machines market.

The inspection machines market is witnessing strong growth, with key players actively investing in research and development to enhance their product offerings and market presence. Technological advancements in the industry include the integration of inspection systems such as weighing machines, metal detectors, and X-ray inspection systems into pharmaceutical, food, and medical production lines. Various combinations of check weighers, metal detectors, and machine inspection systems with work detection systems are improving product packaging and minimizing the recalls of medical devices, food items, and pharmaceutical products across supply chains.

Sensor improvements and CPU processing speeds have increased significantly in the last five years. Moreover, an overall increase in the camera dynamic range and resolution, real-time detection of moving objects, use of color information, analysis of point clouds, cloud computing of machine vision, and computational cameras are some of the major technological advancements expected to be implemented soon in vision inspection systems. Smart camera-based vision inspection systems are well-suited for healthcare applications and are popular due to their lower cost, ease of integration into manufacturing processes, and simple operation.

In response, industry players are focusing on providing embedded smart camera-based systems in their offerings. The advent of integrated inspection machine systems has enabled manufacturers to provide advanced vision and leak detection systems to the pharmaceutical, medical devices, and food industries. Such developments indicate the rising focus of industry players on investing in advanced inspection machine technologies, which is expected to create significant opportunities for the growth of this market.

The integration of cutting-edge technologies, including AI, IoT, machine vision, and 3D, into inspection machines is expected to contribute to the growth of the inspection machines market in the coming years.

Some of the recent technological advancements in the inspection machines industry are as follows:

Globalization has led to a significant rise in the outsourcing of manufacturing operations, particularly in emerging economies. In recent years, emerging economies, particularly in Asia, Latin America, and Eastern Europe, have emerged as key destinations for manufacturing outsourcing. As companies continue to outsource production to these regions, effective quality control and inspection processes have become paramount. Inspection machines play a crucial role in ensuring product quality, safety, and compliance with regulatory standards.

Companies are collaborating to expand and outsource their manufacturing operations in emerging economies, generating demand for inspection machines to ensure product quality and compliance with regulatory standards. For instance:

To meet the evolving demands of the outsourcing market, many inspection machine manufacturers are focusing on diversifying their product offerings to cater to the specific needs of different industries, including pharmaceuticals, food & beverage, automotive, and electronics. In addition, inspection machine manufacturers are investing in R&D to innovate new technologies and enhance the capabilities of their existing products. Through innovation, technological advancements, and strategic partnerships, manufacturers can position themselves for success in a rapidly evolving global market landscape.

In 2024, the hardware segment is expected to account for the largest share of 73.2% of the global inspection machines market. The segment’s growth is driven by the growing adoption of inspection machine hardware in the manufacturing sector, increasing R&D expenditure, and stringent regulations for manufacturing practices.

However, the software segment is projected to record the highest CAGR of 11.6% during the forecast period. Factors such as the growing adoption of inspection machine software in various industrial applications, the rising need for efficient, accurate, and reliable inspection processes, and the rising need for quality control and real-time monitoring are driving the growth of this segment.

In 2024, the automatic inspection segment is expected to account for the largest share of 43.9% of the global inspection machines market. The segment’s large share can be attributed to the benefits offered by automatic inspection machines over manual and semi-automated inspection machines and the rising use of automatic inspection machines by manufacturers for real-time monitoring of the manufacturing process. The automatic inspection segment is also projected to record the highest CAGR of 11.1% during the forecast period.

In 2024, the pharmaceutical & biotech segment is expected to account for the largest share of 36.9% of the global inspection machines market. The large share of the segment is attributed to the stringent regulatory requirements for product quality & safety, increasing adoption of automation & technological advancements in inspection systems, growing demand for biopharmaceuticals, biosimilars, & personalized medicines, and rising focus on reducing production costs, minimizing product recalls, & improving overall manufacturing efficiency. The segment is also projected to record the highest CAGR of 11.0% during the forecast period.

In 2024, Asia-Pacific is expected to account for the largest share of 63.3% of the global inspection machines market, followed by North America, Europe, Latin America, and the Middle East & Africa. The growth of this market can be attributed to the increasing manufacturing activities across several industries, including pharmaceutical and biotech, food & beverage, and cosmetics. The growing demand for quality products from these industries creates potential opportunities for the players in this market. Furthermore, technologically advanced countries, such as China, Japan, South Korea, Taiwan, and India, are expected to offer significant market growth opportunities in the coming years.

Additionally, the market in Asia-Pacific is projected to register the highest CAGR of 9.7% during the forecast period.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the Inspection Machines market are Thermo Fisher Scientific Inc. (U.S.), Teledyne Technologies Incorporated (U.S.), Körber AG (Germany), Robert Bosch GmbH (Germany), OMRON Corporation (Japan), Optel Vision Inc. (Canada), Cognex Corporation (U.S.), Brevetti CEA SpA (Italy), Antares Vision S.p.A. (Italy), ACG (India), IRIS Inspection Machines (France), Sys-Tech Solutions, Inc. (U.S.), ALLTEC Angewandte Laserlicht Technologie GmbH (Germany), Sea Vision S.r.l. (Italy), and CMP PHAR.MA S.R.L. (Italy)

|

Particulars |

Details |

|

Number of Pages |

227 |

|

Format |

|

|

Forecast Period |

2024–2031 |

|

Base Year |

2023 |

|

CAGR (Value) |

9.1% |

|

Market Size (Value) |

USD 2.15 Billion by 2031 |

|

Segments Covered |

By Offering

By Automation Mode

By End User

|

|

Countries Covered |

Europe (France, Germany, U.K., Italy, Spain, Sweden, Netherlands, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, India, Singapore, and Rest of Asia-Pacific), North America (U.S., Canada), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, and Rest of Middle East & Africa) |

|

Key Companies |

Thermo Fisher Scientific Inc. (U.S.), Teledyne Technologies Incorporated (U.S.), Körber AG (Germany), Robert Bosch GmbH (Germany), OMRON Corporation (Japan), Optel Vision Inc. (Canada), Cognex Corporation (U.S.), Brevetti CEA SpA (Italy), Antares Vision S.p.A. (Italy), ACG (India), IRIS Inspection Machines (France), Sys-Tech Solutions, Inc. (U.S.), ALLTEC Angewandte Laserlicht Technologie GmbH (Germany), Sea Vision S.r.l. (Italy), and CMP PHAR.MA S.R.L. (Italy). |

This study offers various insights into the Inspection Machines market segmented based on offering, automation mode, and end user.

The Inspection Machines market is projected to reach $2.15 billion by 2031, at a CAGR of 9.1% during the forecast period.

The hardware segment is expected to account for the largest share of the Inspection Machines market.

The automatic inspection segment is expected to account for the largest share of approximately 43.9% of the Inspection Machines market.

The growth of the inspection machines market is driven by stringent government regulations & compliances related to product quality & safety, the increasing adoption of Industry 4.0 technologies, and the growing demand for automated inspection processes.

Moreover, technological advancements in inspection machines and the increasing outsourcing of manufacturing operations in emerging economies are expected to offer growth opportunities for the players operating in this market.

Thermo Fisher Scientific Inc. (U.S.), Teledyne Technologies Incorporated (U.S.), Körber AG (Germany), Robert Bosch GmbH (Germany), OMRON Corporation (Japan), Optel Vision Inc. (Canada), Cognex Corporation (U.S.), Brevetti CEA SpA (Italy), Antares Vision S.p.A. (Italy), ACG (India), IRIS Inspection Machines (France), Sys-Tech Solutions, Inc. (U.S.), ALLTEC Angewandte Laserlicht Technologie GmbH (Germany), Sea Vision S.r.l. (Italy), and CMP PHAR.MA S.R.L. (Italy).

Asia-Pacific is slated to register the highest growth rate of approximately 9.7% during the forecast period.

Published Date: Jun-2024

Published Date: Jan-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates