Resources

About Us

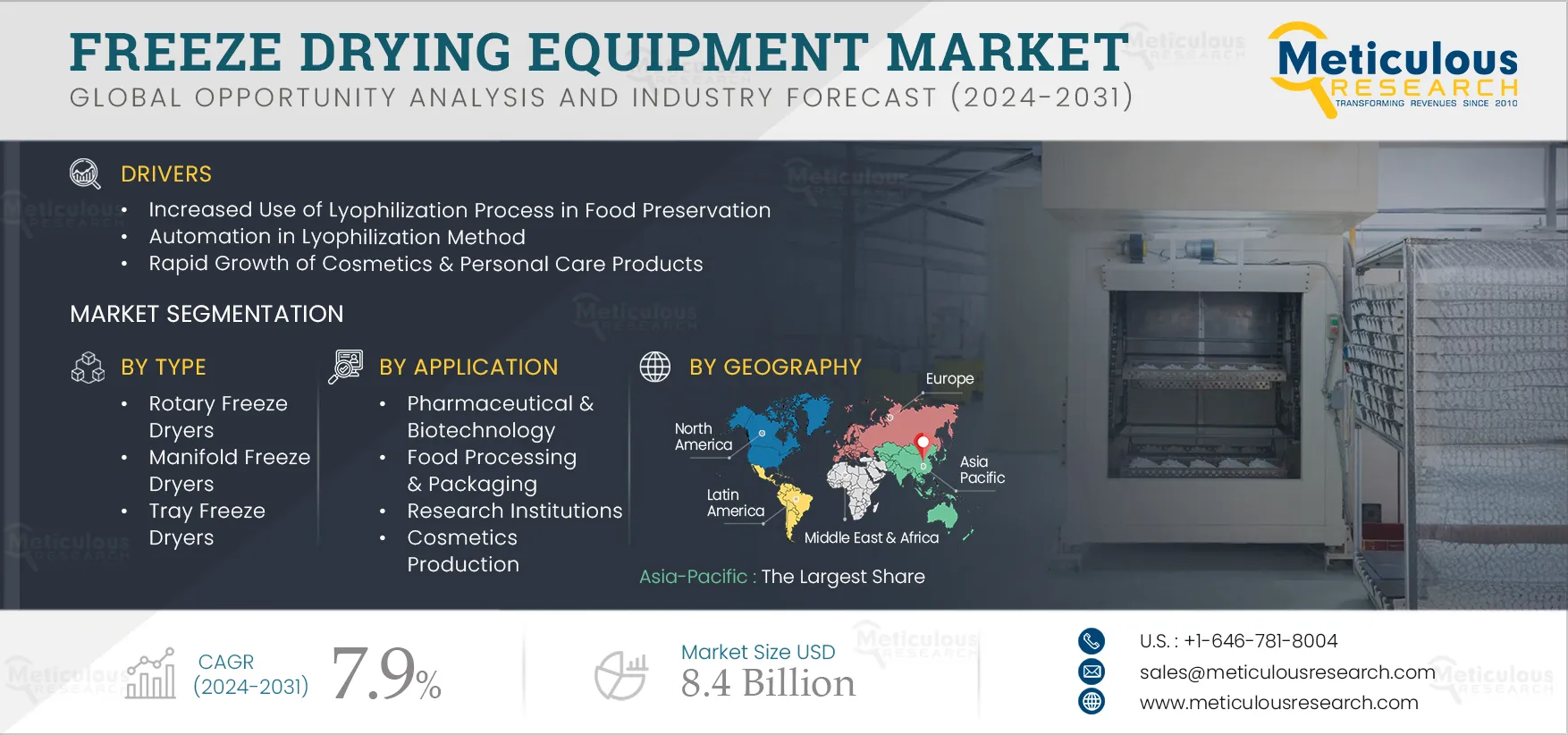

Freeze Drying Equipment Market by Component (Vacuum Systems, Drying Chambers, Refrigeration Systems), Type (Rotary, Tray), Scale of Operation, Application (Pharmaceutical & Biotechnology, Food Processing & Packaging), and Geography - Global Forecast to 2032

Report ID: MRSE - 1041350 Pages: 250 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportThis market's growth is driven by the increasing use of the lyophilization process for food preservation, advancements in the automation of lyophilization methods, and the rapid expansion of the cosmetics and personal care products sector. Furthermore, the rising demand for lyophilized products in the pharmaceutical industry and increased investments in R&D laboratories are anticipated to generate significant growth opportunities for stakeholders in this market.

Key Findings

Click here to: Get Free Sample Pages of this Report

Freeze drying, or lyophilization, is a process that removes water from perishable materials to enhance preservation. During this process, freeze dryers first freeze the material and then reduce the pressure while adding heat, allowing the frozen water to change directly into vapor (sublimation). By eliminating moisture, freeze drying significantly extends the shelf life of food products, inhibiting the growth of bacteria, molds, and other microorganisms, thereby preventing spoilage and degradation.

Lyophilization is employed for food preservation to extend shelf life and enhance transport convenience while retaining the nutritional content of food products. This freeze drying process is used to preserve a variety of items, including vegetables, fruits, spices, herbs, meat, and dairy products. Freeze-dried products are lightweight, compact, and cost-effective, making them ideal for transportation. They are particularly useful in space missions, military operations, and emergency relief efforts, where lightweight, non-perishable foods and medical supplies are essential. Additionally, as consumers increasingly seek healthy and natural food options, they prefer lyophilization for preserving the nutritional value and natural taste of products. These factors have boosted the use of lyophilization for food preservation, further driving growth in the freeze drying equipment market.

Automation has become essential in industries such as pharmaceuticals and food to enhance production rates and efficiency. By incorporating automation into various stages of lyophilization, manufacturers can streamline operations, minimize human error, and optimize production processes. In the freeze drying process, automation is applied in several steps, including loading, and unloading, controlling, and monitoring, and data acquisition and analysis. This integration of automation in the lyophilization process helps improve efficiency, reduce costs, and ensure consistent product quality.

Automated loading and unloading systems utilize robotic arms or conveyor belts to transfer products into and out of the freeze dryer, thereby reducing labor costs and minimizing the risk of contamination while ensuring accuracy and precision. Automated control systems monitor various process parameters, such as temperature, pressure, and vacuum levels, to maintain optimal drying conditions and prevent product damage. This automation not only reduces processing time but also enhances overall productivity. Furthermore, it facilitates compliance with regulatory requirements by providing accurate documentation and traceability, which is crucial for industries such as pharmaceuticals and food processing, where adherence to regulations is essential.

Several organizations are introducing freeze drying equipment to address the growing demand across various applications. For instance, in December 2024, VFL Science Private Limited (India) launched the Penguin Classic, a laboratory freeze dryer/lyophilizer equipped with features like auto defrost and automatic restart after power restoration, tailored for laboratory use. Additionally, the advanced 7-inch touchscreen display allows users to easily program all parameters. Such developments are expected to support the growth of the freeze drying equipment market during the forecast period.

Freeze dryers are essential in pharmaceutical manufacturing for enhancing the stability and shelf life of pharmaceutical products. The freeze drying process, or lyophilization, is particularly valuable for sensitive drugs, vaccines, and biologics, as it removes water while preserving their biological structure and effectiveness. This technology facilitates the preservation of drugs, makes transportation more convenient, and extends storage time. Additionally, utilizing vacuum freeze-drying technology in pharmaceuticals, along with effective drug management practices, helps organizations improve both the preservation conditions and the storage environment for drugs.

Pharmaceutical companies must adhere to stringent standards regarding the production of pharmaceutical products to ensure safety and quality. As a result, organizations prefer lyophilization to maintain the integrity of their products. Companies in this market are actively providing freeze drying equipment tailored for the pharmaceutical industry. For example, in June 2021, SP Industries, Inc. (U.S.) launched the SP Hull LyoStar 4.0, a freeze dryer designed for biopharmaceutical products. This pilot-scale lyophilizer features superior shelf mapping, rapid shelf freezing, and unmatched process accuracy and reliability. Such advancements present significant growth opportunities for the freeze drying equipment market within the pharmaceutical industry during the forecast period.

Based on component, the freeze drying equipment market is segmented into refrigeration systems, vacuum systems, control systems, drying chambers, condensers, loading & unloading systems, shelves, trolleys & trays, heating systems, and other components. In 2025, the loading & unloading systems segment is estimated to account for the largest share of the freeze drying equipment market. The substantial share of this segment is attributed to the growing use of freeze dryers in laboratory and pilot-scale applications, the rising automation of freeze drying equipment for loading and unloading products, and the increasing need for organizations to enhance production rates in the industrial sector.

The loading and unloading systems are critical components of freeze drying equipment, facilitating the transfer of products into and out of the drying chamber. Many manufacturing facilities now utilize automatic loading and unloading systems designed to enhance line efficiency and minimize the risk of cross-contamination during this process. Industries such as pharmaceuticals and food processing heavily rely on these systems for the lyophilization process.

Organizations provide a variety of loading and unloading systems tailored to customer needs and specific applications, including manual, semi-automatic, and automatic systems. Manual systems are typically used in smaller facilities, allowing users to load bulk products into trays or frames. These systems can be static or mounted on loading carts that transport products from the filling area to the freeze drying area. In contrast, automatic systems are predominantly used in industrial settings to transfer large quantities of products efficiently within manufacturing facilities. This versatility and adaptability of loading and unloading systems significantly drive demand for the lyophilization process, further supporting segment growth during the forecast period.

In 2025, Asia-Pacific is estimated to account for the largest share of the freeze drying equipment market. The substantial share of the Asia-Pacific region in the freeze drying equipment market is primarily driven by the rapid growth of the food and pharmaceutical sectors, increased government regulations regarding food product safety, heightened consumer awareness of food quality, and the expansion of key market players in countries like India and China. Government bodies in many Asian nations are providing incentives and investing in freeze drying equipment to foster the growth of these industries. Additionally, the region is experiencing significant advancements in freeze drying technology, including improved vacuum pumps and control systems, which enhance the efficiency and cost-effectiveness of the process. Moreover, APAC is also slated to register the highest CAGR during the forecast period.

The report includes a competitive landscape based on an extensive assessment of the key strategic developments that led market participants to adopt over the past three years (2021-2025).

The key players profiled in the global freeze drying equipment market report GEA Group Aktiengesellschaft (Germany), Tofflon Science and Technology Co., Ltd (China), Labconco Corporation (U.S.), Azbil Corporation (Japan), Millrock Technology, Inc. (U.S.), Cuddon Freeze Dry (New Zealand), HOF Sonderanlagenbau GmbH (Germany), I.M.A. Industria Macchine Automatiche S.p.A. (Italy), ZIRBUS technology GmbH (Germany), MechaTech Systems Ltd (U.K.), BÜCHI Labortechnik AG (Switzerland), OPTIMA packaging group GmbH (Germany), Scala Scientific B.V. (Netherlands), Martin Christ Gefriertrocknungsanlagen GmbH (Germany), and Biopharma Process Systems Ltd. (U.K.).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

7.9% |

|

Market Size (Value) |

USD 8.4 Billion by 2032 |

|

Segments Covered |

By Component

By Type

By Scale of Operation

By Application

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Israel, and Rest of Middle East & Africa) |

|

Key Companies |

GEA Group Aktiengesellschaft (Germany), Tofflon Science and Technology Co., Ltd (China), Labconco Corporation (U.S.), Azbil Corporation (Japan), Millrock Technology, Inc. (U.S.), Cuddon Freeze Dry (New Zealand), HOF Sonderanlagenbau GmbH (Germany), I.M.A. Industria Macchine Automatiche S.p.A. (Italy), ZIRBUS technology GmbH (Germany), MechaTech Systems Ltd (U.K.), BÜCHI Labortechnik AG (Switzerland), OPTIMA packaging group GmbH (Germany), Scala Scientific B.V. (Netherlands), Martin Christ Gefriertrocknungsanlagen GmbH (Germany), and Biopharma Process Systems Ltd. (U.K.) |

Key Questions Answered in the Freeze Drying Equipment Market Report:

The global freeze drying equipment market size was valued at $4.7 billion in 2024.

The market is projected to grow from $4.9 billion in 2025 to $8.4 billion by 2032.

The freeze drying equipment market analysis indicates a significant growth to reach $8.4 billion by 2032, at a compound annual growth rate (CAGR) of 7.9% from 2025 to 2032.

The key companies operating in this market include GEA Group Aktiengesellschaft (Germany), Tofflon Science and Technology Co., Ltd (China), Labconco Corporation (U.S.), Azbil Corporation (Japan), Millrock Technology, Inc. (U.S.), Cuddon Freeze Dry (New Zealand), HOF Sonderanlagenbau GmbH (Germany), I.M.A. Industria Macchine Automatiche S.p.A. (Italy), ZIRBUS technology GmbH (Germany), MechaTech Systems Ltd (U.K.), BÜCHI Labortechnik AG (Switzerland), OPTIMA packaging group GmbH (Germany), Scala Scientific B.V. (Netherlands), Martin Christ Gefriertrocknungsanlagen GmbH (Germany), and Biopharma Process Systems Ltd. (U.K.).

A prominent market trend in the freeze drying equipment market is the development of miniature and portable freeze drying units and customized freeze drying solutions.

Which segments will hold large market shares in the Freeze Drying Equipment Market during 2025-2032?

By Component, the loading & unloading systems segment is forecasted to hold the largest market share.

By Type: the tray freeze dryers segment is expected to dominate the market.

By Scale of Operation, the production freeze drying equipment segment is poised to record the dominant position in the market.

By Application, the food processing & packaging segment is poised to record the dominant position in the market.

By Geography, the Asia-Pacific segment is slated to register the largest market share.

By region, Asia-Pacific will hold the largest share of the Freeze Drying Equipment Market in 2025 and is also expected to witness the fastest growth.

The primary drivers of the Freeze Drying Equipment Market Growth include the increased use of the lyophilization process in food preservation, automation of the lyophilization method, and the rapid growth of cosmetics and personal care products.

Published Date: Nov-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates