Resources

About Us

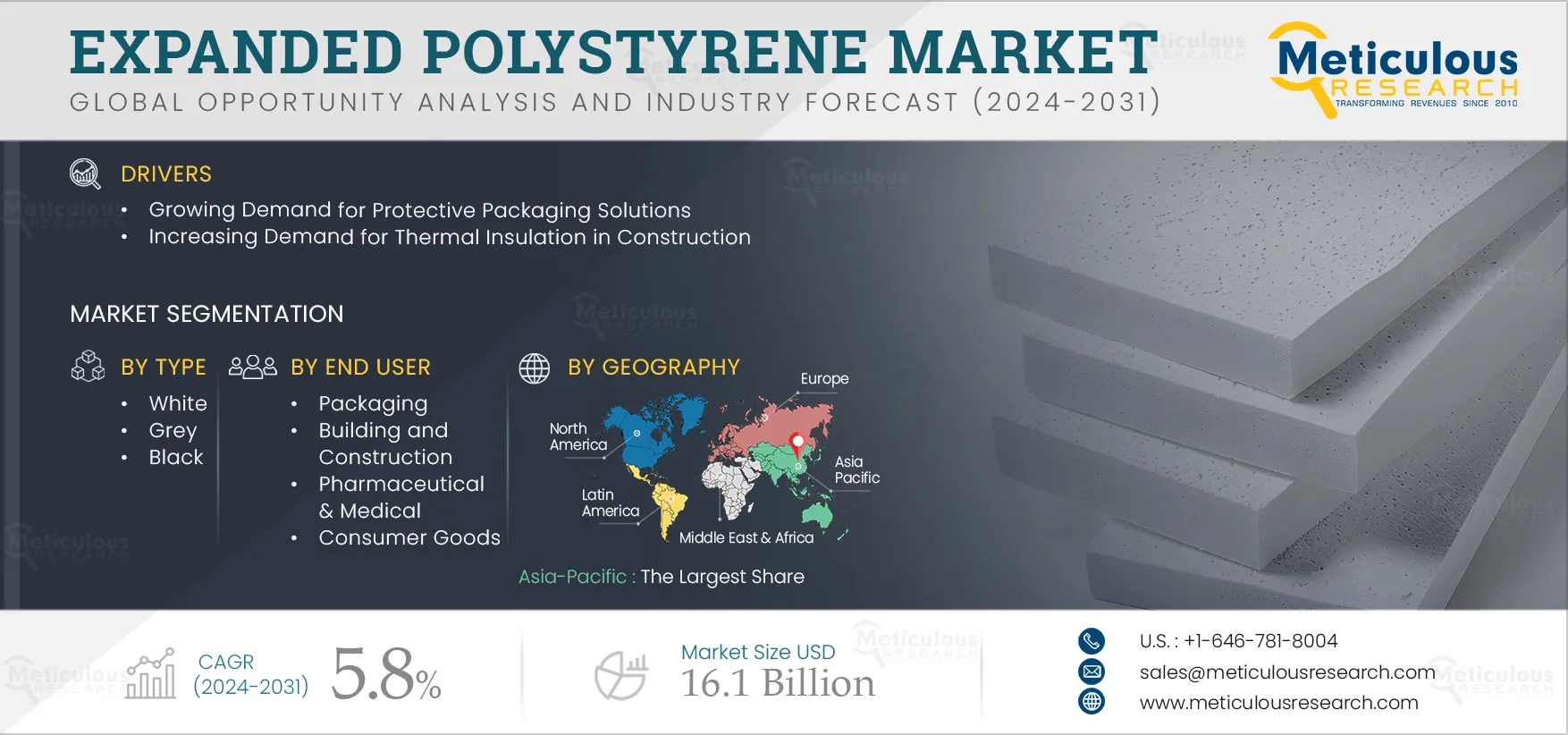

Expanded Polystyrene Market Size, Share, Forecast, & Trends Analysis by Type (White, Grey, Black), Form (Sheets, Foam, Foam), End User (Packaging, Building and Construction, Consumer Goods), and Geography—Global Forecast to 2032

Report ID: MRCHM - 1041374 Pages: 200 Oct-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThis market's growth is driven by a growing demand for protective packaging solutions and an increasing demand for thermal insulation in construction. Furthermore, the surging demand from the automotive industry and increasing demand for insulated packaging for temperature-sensitive products in healthcare are expected to generate growth opportunities for the stakeholders in this market.

In recent years, demand for proactive packaging solutions has surged due to factors such as the growth of e-commerce, the shipping of fragile goods, and the need for quality and safety in perishable items. Expanded polystyrene (EPS) plays a crucial role in addressing this demand for protective packaging due to its unique properties and advantages. EPS is lightweight, which helps reduce shipping costs for companies, making it an ideal choice for protective packaging. Additionally, its excellent thermal insulation properties make it suitable for packaging temperature-sensitive goods like food and pharmaceuticals. The increasing use of EPS in packaging is also attributed to its moisture resistance, which protects products from water damage and helps maintain product integrity during transit.

Furthermore, the growth of e-commerce is driving demand for effective protective packaging solutions. Food & beverage companies are increasingly adopting EPS to maintain the temperature of hot and cold food during transit, making it ideal for catering services and food delivery. As awareness of the benefits of EPS for proactive packaging rises, numerous providers are launching EPS-based solutions. For instance, in April 2025, BEWI ASA (Norway) introduced new grades of expanded polystyrene (EPS) raw materials and EPS fish boxes with improved environmental footprints. These innovations, based on recycled feedstock, are reported to reduce carbon dioxide (CO₂) emissions by up to 60%. Such advancements are expected to further boost demand for EPS in proactive packaging solutions throughout the forecast period.

Expanded Polystyrene (EPS) is increasingly utilized in the automotive industry for manufacturing various components and packaging solutions. Its advantageous properties, particularly excellent insulation capabilities, make it ideal for use in parts such as door panels, where it provides thermal and acoustic insulation, enhancing the overall comfort and quietness of the vehicle interior.

Moreover, EPS is used in the automotive industry for packaging delicate and sensitive parts, providing cushioning and protection to prevent damage during transportation and handling. Its ability to be molded into various shapes and sizes allows for adaptability across a wide range of automotive components, from air ducts to structural support elements, enabling the creation of complex and customized parts. Additionally, EPS is utilized in various interior components, including seat cushions, headrests, and armrests, where its cushioning and shock-absorbing properties enhance the comfort and safety of vehicle occupants. These growing advantages are driving increased demand for EPS in the automotive sector.

Click here to: Get Free Sample Pages of this Report

Based on type, the expanded polystyrene market is segmented into white, grey, and black. In 2025, the white segment is estimated to account for the largest share of the expanded polystyrene market. The substantial share of this segment can be attributed to the growing adoption of white EPS in food packaging, including food trays, drink cups, and clamshell containers, as well as in consumer goods packaging. The material's ability to be molded into various shapes and sizes further enhances its appeal, making it suitable for numerous applications ranging from construction panels to custom packaging solutions.

White EPS is produced from virgin polystyrene beads, which are expanded using steam and molded into shape. This material typically contains no recycled content and is characterized by its uniform white color. As a lightweight, rigid, and closed-cell insulation material, white EPS is widely utilized in construction and packaging. Its cellular structure provides excellent thermal insulation properties.

Known for its versatility, durability, moisture resistance, and affordability, white EPS is a popular choice across various industries. It is commonly used for insulation in walls, roofs, floors, and foundations and as packaging materials that protect fragile items during transportation. Additionally, its cost-effectiveness compared to other insulation materials, along with its availability and ease of manufacturing, makes white EPS an economical choice for insulation projects.

In 2025, Asia-Pacific is estimated to account for the largest share of the global expanded polystyrene market. North America's large share is primarily attributed to the wide presence of EPS manufacturing companies, strong demand for expanded polystyrene from the region’s electronics industry, rise in demand for polystyrene for energy insulation, high demand for EPS in the automotive sector, and rising infrastructure developments across the region. Furthermore, Asia-Pacific is slated to register the highest CAGR during the forecast period.

The report features a competitive landscape derived from a comprehensive analysis of key strategic developments that market participants have implemented over the past three years (2021-2025).

The key players profiled in the expanded polystyrene market report BASF SE (Germany), TotalEnergies SE (France), Synthos S.A. (Poland), Kaneka Corporation (Japan), ALPEK, S.A.B. de C.V. (Mexico), Ravago Manufacturing (U.S.), Atlas Roofing Corporation (U.S.), Versalis S.p.A. (Italy), SIBUR International GmbH (Austria), SABIC (Saudi Arabia), NOVA Chemicals Corporation (Canada), Supreme Petrochem Ltd (India), Epsilyte LLC (U.S.), BEWI ASA (Norway), and Knauf Appliances (India).

|

Particulars |

Details |

|

Number of Pages |

200 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

5.8% |

|

Market Size (Value) |

USD 16.1 Billion by 2032 |

|

Segments Covered |

By Type

By Form

By End User

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, Sweden, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia & New Zealand, Indonesia, Singapore, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Saudi Arabia, Israel, and Rest of Middle East & Africa) |

|

Key Companies |

BASF SE (Germany), TotalEnergies SE (France), Synthos S.A. (Poland), Kaneka Corporation (Japan), ALPEK, S.A.B. de C.V. (Mexico), Ravago Manufacturing (U.S.), Atlas Roofing Corporation (U.S.), Versalis S.p.A. (Italy), SIBUR International GmbH (Austria), SABIC (Saudi Arabia), NOVA Chemicals Corporation (Canada), Supreme Petrochem Ltd (India), Epsilyte LLC (U.S.), BEWI ASA (Norway), and Knauf Appliances (India) |

The expanded polystyrene market size was valued at $10.5 billion in 2024.

The market is projected to grow from $10.9 billion in 2025 to $16.1 billion by 2032.

The expanded polystyrene market analysis indicates a significant growth to reach $16.1 billion by 2032, at a compound annual growth rate (CAGR) of 5.8% from 2025 to 2032.

The key companies operating in this market include BASF SE (Germany), TotalEnergies SE (France), Synthos S.A. (Poland), Kaneka Corporation (Japan), ALPEK, S.A.B. de C.V. (Mexico), Ravago Manufacturing (U.S.), Atlas Roofing Corporation (U.S.), Versalis S.p.A. (Italy), SIBUR International GmbH (Austria), SABIC (Saudi Arabia), NOVA Chemicals Corporation (Canada), Supreme Petrochem Ltd (India), Epsilyte LLC (U.S.), BEWI ASA (Norway), and Knauf Appliances (India).

A prominent market trend in expanded polystyrene is the rising demand for EPS in food packaging and the growing demand for EPS in E-commerce for packaging fragile items.

By type, the white segment is forecasted to hold the largest market share.

The sheets sensors segment is expected to dominate the market by form.

By end user, the packaging segment is poised to record the dominant position in the market.

By geography, the Asia-Pacific segment is slated to register the largest market share.

By region, Asia-Pacific holds the largest expanded polystyrene Market Share in 2025. The region is also expected to witness the fastest growth, driven by the wide presence of EPS manufacturing companies, strong demand for expanded polystyrene from the region’s electronics industry, a rise in demand for polystyrene for energy insulation, and high demand for EPS in the automotive sector.

The primary drivers of expanded polystyrene market growth are the growing demand for protective packaging solutions and the increasing demand for thermal insulation in construction.

Published Date: May-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates