Resources

About Us

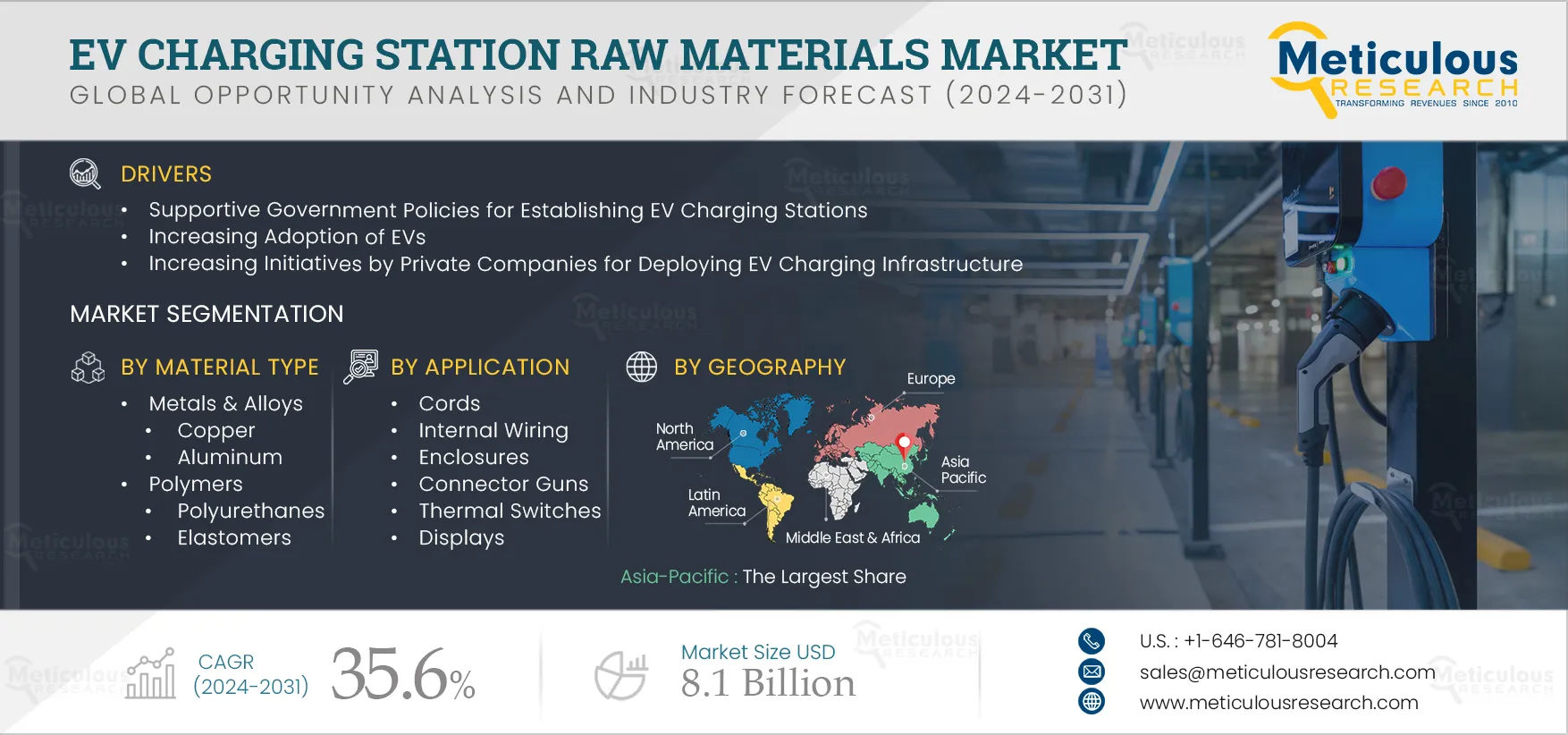

EV Charging Station Raw Materials Market Size, Share, Forecast, & Trends Analysis by Material Type (Metals & Alloys (Stainless Steel, Aluminum, Copper), Polymers (PC Resins, Elastomers, TPU), Application (Cords, Displays), Charging Type, and Geography - Global Forecast to 2031

Report ID: MRAUTO - 104507 Pages: 307 May-2024 Formats*: PDF Category: Automotive and Transportation Delivery: 24 to 48 Hours Download Free Sample ReportThe EV Charging Station Raw Materials Market is expected to reach $8.1 billion by 2031, at a CAGR of 35.6% from 2024 to 2031. The growth of the EV charging station raw materials market is driven by supportive government policies for establishing EV charging stations, increasing adoption of EVs, and increasing initiatives by private companies for deploying EV charging infrastructure. Furthermore, the increasing adoption of electric mobility in emerging economies is expected to generate growth opportunities for the stakeholders in this market.

With advancements in electric drivetrain technology, governments worldwide are pushing for transitioning to EVs as a sustainable public and private transportation model. Charging stations are an important part of the electric vehicle ecosystem. Several governments worldwide are providing funding for charging infrastructure development. Furthermore, the environmental benefits of EVs have prompted governments to offer incentives and subsidies for purchasing them and associated charging infrastructure.

Some of the recent government initiatives aimed at establishing EV charging stations are as follows:

Such government initiatives are driving the growth of the EV charging stations market, which, in turn, is expected to accelerate the demand for raw materials used in producing these stations.

Click here to: Get Free Sample Pages of this Report

With the rapid adoption of EVs, the demand for charging infrastructure to support the transition to electric mobility is also on the rise. EV drivers now seek fast charging options at major highways, retail shops, workplaces, restaurants, and near multi-dwelling apartments for convenient vehicle charging. In response to this growing demand, owners of retail shops, residential apartments, and commercial spaces are installing EV charging stations to enhance the eco-friendly reputation of their establishments and attract more customers by offering value-added EV charging services.

Stringent government regulations on carbon emissions and rising environmental consciousness have prompted automakers to develop new plug-in hybrids and EVs. In August 2021, the U.S. Senate passed a USD 1 trillion infrastructure bill, earmarking significant investments in electric vehicle infrastructure, including charging stations, alongside funding for EV manufacturing and research. This legislation was aimed at expediting the transition to EVs and curbing greenhouse gas emissions. Such initiatives are anticipated to drive the growth of the EV charging station raw materials market during the forecast period.

EVs have witnessed rapid evolution with the ongoing developments in the automotive sector. The rising consumer preference for shared mobility, growing adoption of mobility-as-a-service (MaaS), declining costs of high-capacity batteries, and significant investments by EV manufacturers are fueling electric mobility adoption in emerging regions.

There are still challenges that need to be addressed, including regulatory barriers, technological limitations, and public perception. As technology continues to evolve and improve, Autonomous Electric Vehicles (AEVs) are likely to gain traction. The increasing adoption of electric mobility in emerging economies can positively impact the environment, energy security, and economic development. Countries like South Africa, Kenya, Rwanda, Egypt, Vietnam, and Malaysia are actively promoting electric mobility through incentives such as tax breaks and reduced customs duties for EVs and components. Furthermore, several nations have launched initiatives for reducing greenhouse gas emissions, improving air quality, or increasing the adoption of sustainable modes of transport like electric vehicles. These factors are expected to offer opportunities for the growth of the EV charging station raw materials market.

Based on material type, the global EV charging station raw materials market is segmented into metals & alloys and polymers. In 2024, the metals & alloys segment is expected to account for the larger share of over 60% of the global EV charging station raw materials market. This segment’s large market share can be attributed to the surge in electric vehicle adoption, increasing investments and initiatives by electric mobility stakeholders to deploy wireless EV charging systems, and increasing government initiatives aimed at promoting the use of EVs. Metals and alloys possess the essential physical and aesthetic properties necessary for manufacturers to meet design and operational standards for electric vehicles and charging stations at optimal prices. Among these, stainless steel, aluminum, copper, nickel, and titanium are the most utilized raw materials within the electric mobility ecosystem.

However, the polymer segment is projected to register a higher CAGR during the period. This growth is attributed to the rising demand for various polymers used in EV charging stations, coupled with the increasing focus on sustainability in sourcing materials. Polymers are utilized for making enclosures, cable coatings, flexible conduits, plug holsters, connectors, and displays for EV charging stations. These lightweight materials offer excellent durability and heat resistance while being easily moldable into various shapes and sizes.

Based on application, the global EV charging station raw materials market is segmented into cords, connector guns, enclosures, charger plug holsters, nylon glands/lock nuts, electric circuit breakers, energy meters and timers, internal wiring, flexible conduits, thermal switches, cable hangers, displays, and other applications. In 2024, the cords segment is expected to account for the largest share of over 61% of the global EV charging station raw materials market. This segment’s large market share can be attributed to the frequent replacement of EV charging station cords due to their low operational lifespan, the global surge in EV adoption, the rising demand for high-power charging (HPC) cables, and technological advancements in EV charging cables, including innovations like liquid-cooling.

However, the connector guns segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by several factors, including the rising demand for DC fast-charging stations in European countries and the U.S., the rising adoption of electric mobility in emerging economies, and the growing initiatives by governments in countries like India, Thailand, Singapore, and other Southeast Asian nations aimed at accelerating the deployment of EV charging infrastructure and foster the development of an EV ecosystem, including the manufacturing of Electric Vehicle Supply Equipment (EVSE) components.

Based on charging type, the global EV charging station raw materials market is segmented into Level 1 charging, Level 2 charging, and DC fast-charging. In 2024, the Level 2 charging segment is expected to account for the largest share of over 85% of the global EV charging station raw materials market. This segment’s large market share can be attributed to increasing government funding and incentives aimed at the installation of Level 2 charging stations, the lower installation costs of Level 2 charging stations compared to DC fast-charging stations, and their greater efficiency, offering reduced charging times compared to Level 1 charging stations.

However, the DC fast-charging segment is projected to register the highest CAGR during the forecast period. The growth of this segment can be attributed to increasing government initiatives aimed at installing fast-charging stations, rebates offered on the purchase of DC fast-charging stations, rising investments from automakers in the development of DC fast-charging station infrastructure to support their long-range battery-electric vehicles, and the superior charging speed provided by DC fast chargers compared to Level 1 and Level 2 charging stations.

In 2024, Asia-Pacific is expected to account for the largest share of over 59% of the global EV charging station raw materials market. Asia-Pacific’s significant market share can be attributed to the growing demand for EVs in countries such as China and Japan and rising government initiatives to reduce greenhouse gas emissions. Additionally, electrification presents various opportunities across the value chain. For economies with well-established automotive manufacturing hubs like Indonesia and Thailand, it offers opportunities to expand their EV and charging station production. Moreover, it allows less developed economies to advance their automotive manufacturing capabilities. Moreover, the market in Asia-Pacific is projected to record the highest CAGR of over 38% during the forecast period.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios and geographic presence and the key growth strategies adopted by them over the past 3–4 years. Some of the key players operating in the EV charging station raw materials market are Ryerson Holding Corporation (U.S.), DOMO Chemicals GmbH (Germany), DuPont de Nemours, Inc. (U.S.), SABIC (Saudi Arabia), BASF SE (Germany), thyssenkrupp AG (Germany), Covestro AG (Germany), Evonik Industries AG (Germany), POSCO (South Korea), Trinseo S.A. (U.S.), Celanese Corporation (U.S.), and Lanxess AG (Germany).

|

Particulars |

Details |

|

Number of Pages |

307 |

|

Format |

|

|

Forecast Period |

2024–2031 |

|

Base Year |

2023 |

|

CAGR (Value) |

35.6% |

|

Market Size (Value) |

USD 8.1 Billion by 2031 |

|

CAGR (Volume) |

12.7% |

|

Market Size (Volume) |

1,09,248.5 metric tons by 2031 |

|

Segments Covered |

By Material Type

By Application

By Charging Type

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Morocco, Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Singapore, Rest of Asia-Pacific), Latin America (Mexico, Brazil, Rest of Latin America), and the Middle East & Africa (UAE, Israel, Rest of Middle East & Africa) |

|

Key Companies |

Ryerson Holding Corporation (U.S.), DOMO Chemicals GmbH (Germany), DuPont de Nemours, Inc. (U.S.), SABIC (Saudi Arabia), BASF SE (Germany), thyssenkrupp AG (Germany), Covestro AG (Germany), Evonik Industries AG (Germany), POSCO (South Korea), Trinseo S.A. (U.S.), Celanese Corporation (U.S.), and Lanxess AG (Germany) |

This study focuses on market assessment and opportunity analysis by analyzing the sales of EV charging station raw materials across various regions and countries. This study also offers a competitive analysis of the EV charging station raw materials market based on an extensive assessment of the leading players' product portfolios, geographic presence, and key growth strategies.

The global EV charging station raw materials market is projected to reach $8.1 billion by 2031, at a CAGR of 35.6% during the forecast period.

In 2024, the metals & alloys segment is expected to account for the larger share of over 60% of the EV charging station raw materials market.

Based on application, the connector guns segment is projected to register the highest CAGR during the forecast period.

The growth of the EV charging station raw materials market is driven by supportive government policies for establishing EV charging stations, increasing adoption of EVs, and increasing initiatives by private companies for deploying EV charging infrastructure. Furthermore, the increasing adoption of electric mobility in emerging economies is expected to generate growth opportunities for the stakeholders in this market.

The key players operating in the global EV charging station raw materials market are Ryerson Holding Corporation (U.S.), DOMO Chemicals GmbH (Germany), DuPont de Nemours, Inc. (U.S.), SABIC (Saudi Arabia), BASF SE (Germany), thyssenkrupp AG (Germany), Covestro AG (Germany), Evonik Industries AG (Germany), POSCO (South Korea), Trinseo S.A. (U.S.), Celanese Corporation (U.S.), and Lanxess AG (Germany).

Asia-Pacific is projected to register the highest CAGR of over 38% during the forecast period and offer significant growth opportunities for vendors operating in this market.

The EV Charging Station Raw Materials Market is expected to reach a value of $8.1 billion by 2031, at a CAGR of 35.6% during the forecast period 2024-2031.Factors such as supportive government policies for establishing EV Charging Station Raw Materials Market increasing adoption of EVs, and increasing initiatives by private companies for deploying EV charging infrastructure are driving the growth of the EV charging stations raw materials market. However, the potential shortfall in mining capabilities and environmental effects of illegal mining in ecologically sensitive regions are likely to hinder the market’s growth. In addition, the increasing adoption of electric mobility in emerging economies is projected to provide significant growth opportunities for vendors operating in EV Charging Station Raw Materials Market

Here are the top 10 companies operating in the EV Charging Station Raw Materials Market

POSCO

Founded in 1968 and headquartered in Pohang-si, South Korea, POSCO provides a wide range of hot-rolled products, cold-rolled products, plate products, wire rod products, electrical steel products, and stainless-steel products. With its subsidiaries and a strong distribution network, the company has its presence across South Korea, Japan, China, Asia (others), North America, and other regions. The company operates through four reportable segments Steel, Trade, Construction, and Others. POSCO caters to different industries, including automotive, construction, shipbuilding, energy, home appliances, and industrial machinery.

Covestro AG

Founded in 2015 and headquartered in Leverkusen, Germany, Covestro produces various polyurethane and polycarbonate-based raw materials. In addition, the company develops sustainable solutions to address climate change, resource depletion, urban expansion, population growth, and the resulting increase in awareness of environmental issues. Covestro provides various solutions, including 3D printers, composites, foams, adhesives, elastomers, plastics, coatings, films, and thermoplastic polyurethane. With its subsidiary and strong distribution network, the company has its global presence across Germany, the United States, China, and other regions. The company operates through four reportable segments Polyurethanes, Polycarbonates, Coatings, Adhesives, Specialties, and Other segments. Covestro caters to various industries, including automotive, construction, cosmetics, electronics, electrical & appliances, energy, healthcare, industrial & agricultural applications, marine & ships, packaging & print, rail, security & protection, sports & leisure, and wood & furniture.

DuPont de Nemours, Inc.

Incorporated in 2019 and headquartered in Delaware, U.S., DuPont is a leading supplier of high-performance engineering polymers, resins, adhesives, specialty pastes & films. DuPont operates through five reportable segments: Electronics & Imaging; Nutrition & Biosciences; Transportation & Industrial; Safety & Construction; and Non-Core. Through its Transportation & Industrial segment, DuPont de Nemours, Inc. operates in the EV charging station raw materials market. Major products offered by the company in this market are DUPONT ZYTEL nylon resins, CRASTIN PBT thermoplastic polyester resin, RYNITE PET polyester resin, and TYNEX filaments. With its strong distribution network, the company has its presence across North America, Asia-Pacific, Europe, and Latin America.

BASF SE

Founded in 1865 and headquartered in Ludwigshafen, Germany, BASF SE is a multinational chemical company and the largest chemical producer in the world. BASF provides a wide range of products consist agriculture, automotive & transportation, chemicals, coating solutions, construction, electronics & electric, energy & resources, furniture & wood, home care and I&I cleaning, nutrition, packaging & print, paints & coatings, personal care & hygiene, pharmaceuticals, plastic & rubber, product finder, pulp & paper, textile, leather & footwear, and segments. The company operates through seven reportable segments Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care, Agricultural Solutions, and Others. BASF provides engineering plastics, polyurethane, and specialty foams, coatings, pigments, catalysts, axle and transmission lubricants, fuel additives, coolants, and brake fluids, as well as battery materials for e-mobility. With its subsidiary and strong distribution network, the company has its presence across Germany, the United States, the United Kingdom, and Europe.

SABIC

Founded in 1976 and headquartered in Riyadh, Saudi Arabia, Saudi Basic Industries Corporation, known as SABIC, is a Saudi Arabian multinational chemical manufacturing company that provides chemicals, agri-nutrients, plastics, and metals. SABIC provided various products and services, including polymer, specialties, chemicals, agri-nutrients, metals, e-business, and services. The company operates through three reportable segments Petrochemicals and Specialties, Agri-Nutrient, and Hadeed. SABIC caters to agriculture, automotive, building & construction, consumer, electrical & electronics, healthcare, industrial, mass transportation, and packaging industries. In addition, SABIC provides a wide range of polymer material solutions to EVSE manufacturers for manufacturing connectors and sockets, support frames, console units, displays, port covers, and exterior fascia of EV charging stations. With its subsidiary and strong distribution network, the company has its global presence across KSA, China, Europe, the Americas, Asia, and others.

Ryerson Holding Corporation

Founded in 1842 and headquartered in Chicago, U.S., Ryerson Holding is a leading processor and distributor of industrial metals worldwide. The company offers various metals and alloys for industrial and automotive applications, such as steel, stainless steel, aluminum, alloy, nickel, brass, copper, and bronze. Ryerson focuses on sheet & coil processing, plate processing, bar, tube & structural processing, and supply chain services. In addition, the company provides metal alloys to charging station manufacturers for manufacturing NEMA 4 and 4X enclosures. With its subsidiary and strong distribution network, the company has its presence across the U.S., Canada, China, and Mexico. The company operates through one operating and reportable segment, Metals Service Centers.

DOMO Chemicals

Founded in 2013 and headquartered in Leuna, Germany, DOMO Chemicals is a leading manufacturer of engineering materials and polyamides. The company offers a wide range of polyamide products, such as polyamide 6/6.6 intermediates, polyamide 6/6.6 resins, engineered materials, performance fibers, fertilizers, and petrochemical products. DOMO Chemicals caters to various industries, such as mobility, health & wellbeing, urbanization, and lifestyle. Its polymer products are extensively used in various end-use applications, such as automotive, fibers & yarns, electrical & electronic, and industrial & consumer goods. DOMO Chemicals consist of Chemical Intermediates, Domamid Engineering Plastic, Domamid Virgin Resins, DOMOgran 45, Econamid, Stabamid Virgin Grades, Technyl Engineering Plastics, and Thermec brands. In addition, the company also provides polyamide solutions for manufacturing HV plugs, cables, and connectors for EV charging stations. With its strong distribution network, the company has its presence across North America, Asia, and Europe.

Thyssenkrupp AG

Founded in 1999 and headquartered in Essen, Germany, thyssenkrupp is a multinational conglomerate focusing on industrial engineering and steel production. The company provides a wide range of products, including hot strip, middle band, strip sheet, heavy plate, thin sheet/surface-refined products, organically coated strip and sheet, electrical steel, packaging steel, composite material, and byproducts. The company operates through seven reportable segments: Automotive Technology, Industrial Components, Elevator Technology, Plant Technology, Marine Systems, Materials Services, and Steel Europe. thyssenkrupp caters to different industry sectors, including automobile/trucks, construction, machine/plant construction, energy, special vehicles, packaging, and household. In addition, the company provides electrical steel for manufacturing transformers. With its subsidiary and strong distribution network, the company has its global presence across Germany, the U.S., China, and Outside Germany.

Evonik Industries AG

Founded in 2007 and headquartered in Essen, Germany, Evonik is one of the world’s leading specialty chemicals companies and provides specialty chemicals, animal nutrition, specialty additives, smart materials, health, care, cosmetic solutions, high-performance polymers, membranes, silica, innovation, sustainability, resource efficiency, and nutrition. In addition, Evonik Industries provides various products and solutions, including adhesives & sealants, analytics – laboratory specialist, plant care, and composites, for automotive, construction, food, medical technology, oil & gas, and tire and rubber industries. With its subsidiaries and a strong distribution network, the company has its presence across Asia-Pacific, Europe, Middle East & Africa, North America, and Central & South America. The company operates through five reportable segments—Specialty Additives, Nutrition & Care, Smart Materials, Performance Materials, and Services. The company caters to different markets, including adhesives & sealants, animal nutrition, automotive, agriculture, coatings, composites, construction, design, electronics and telecommunications, environment and utilities, food, beverages & supplements, household care, lifestyle, metal, mining, oil, and gas, optics, personal care, pharmaceuticals and health, plastics and general industry, printing, and pulp, paper, and packaging.

Trinseo S.A.

Founded in 2010 and headquartered in Pennsylvania, U.S., Trinseo is a global materials solutions provider and manufacturer of plastics, latex binders, and synthetic rubber with a focus on delivering innovative, sustainable, and value-creating products. With its subsidiaries and a strong distribution network, the company has its presence across North America, Latin America, EMEA, and Asia-Pacific. The company operates through six reportable segments Latex Binders, Synthetic Rubber, Engineered Materials, Base Plastics, Polystyrene, and Feedstocks. The company has 17 manufacturing sites located strategically around the world. Trinseo caters to industries including automotive, personal care, edgebands, footwear, building & construction, consumer electronics, consumer goods, home appliances, medical, packaging, sheet & profile extrusion, CASE, paper & board, textiles & carpet, tires, and technical rubber goods.

Published Date: Apr-2024

Published Date: Jan-2024

Published Date: Jun-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates