Resources

About Us

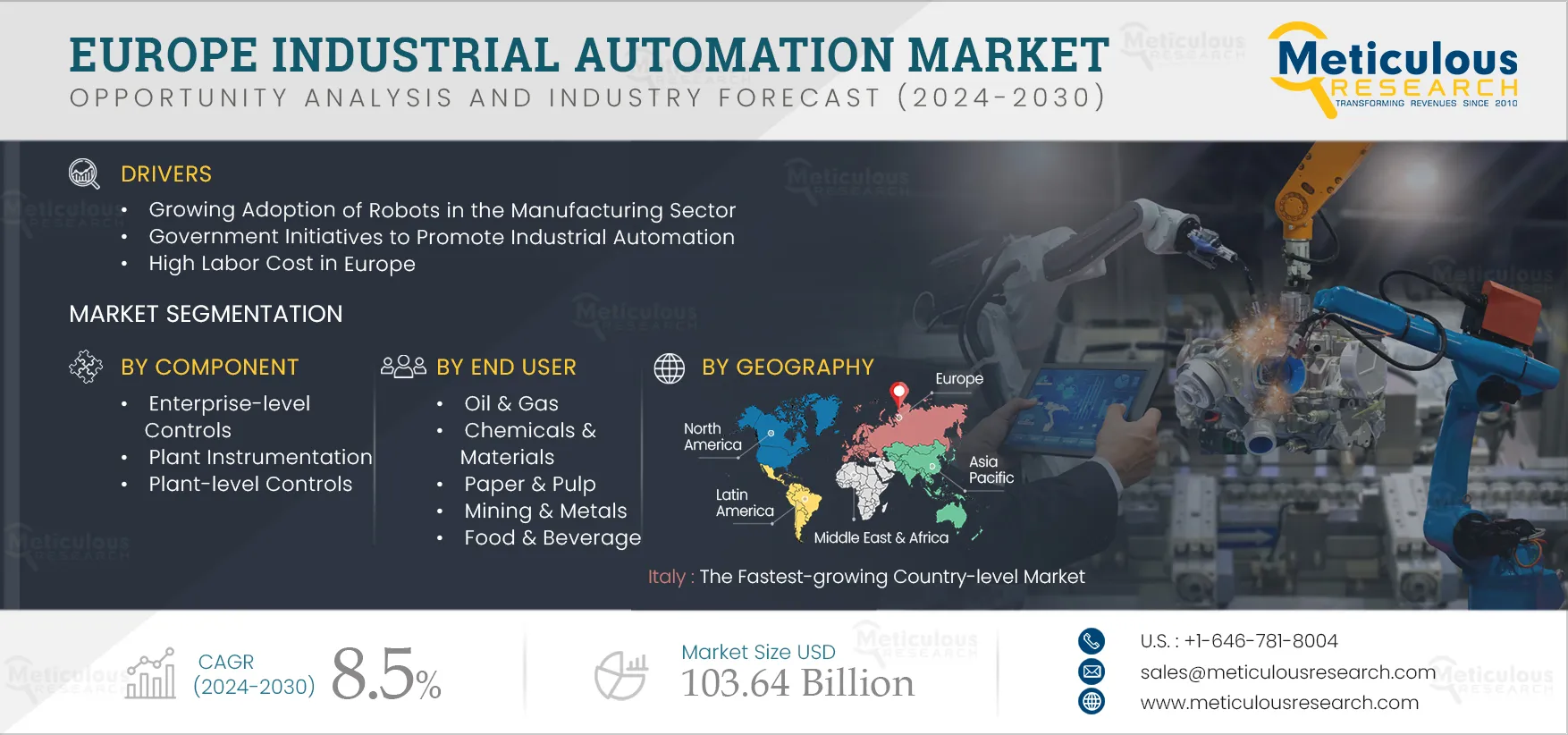

Europe Industrial Automation Market by Component (Plant-level Controls, Enterprise-level Controls, Plant Instrumentation), Mode of Automation (Semi, Fully Automatic), End User (Oil & Gas, Automotive, F&B, Others), and Geography - Forecast to 2032

Report ID: MRICT - 104956 Pages: 200 Jan-2025 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportThe Europe Industrial Automation Market is projected to reach $103.64 billion by 2032, at a CAGR of 8.5% from 2025 to 2032. The growth of this market is driven by the growing adoption of robots in the manufacturing sector, government initiatives to promote industrial automation, high labor costs in Europe, growing demand for safe & digitized production processes, and increasing investments in transforming conventional production facilities. The growing number of SMEs and rising demand for IIoT in the manufacturing sector are expected to offer significant growth opportunities for the European industrial automation market stakeholders. The high initial investment may restrain the market's growth.

Industries are relying on automation for cost-cutting benefits. Automation systems provide a faster response by real-time monitoring methods so that precautions can be taken before breakdowns. Automation reduces the risk of injuries as companies replace human labor with machines and robots to perform dangerous tasks.

According to International Labour Organization estimates, about 2.3 million men and women worldwide die from work-related illnesses or accidents yearly, or more than 6,000 people per day. Each year, there are over 160 million cases of work-related disease and 340 million occupational accidents worldwide. According to the European Commission, Europe had 2.7 million non-fatal accidents in 2020. There is a need for regulations regarding worker safety due to high risks. The European Union proposed a directive to lay down minimum health and safety requirements for manual handling of loads where there is a risk, particularly of back injury to workers. Hence, such huge numbers of work-related accidents are increasing the industry's demand for safe and digitized production processes.

Click here to: Get Free Sample Pages of this Report

Furthermore, several companies operating in the market emphasize product development for safe and digitized industrial automation processes. For instance, in November 2021, ABB Ltd. (Switzerland) launched ABB Ability Smart Melt Shop, the first smart factory digital application for the metals industry. It is designed to increase melt shop productivity, save energy, and improve employee safety. Such product development for creating a safe environment for the employee in the factory drive the industrial automation market.

According to the Occupational Safety and Health Administration, worker injuries had decreased from 10.9 incidents per 100 workers in 1972 to 2.7 per 100 workers in 2020. This was achieved due to increased demand for industrial robots in the manufacturing, logistics, and transportation sectors. The presence of industrial, collaborative, and warehouse robots is increasing, ensuring a sophisticated safety environment for employees.

Key Findings in the Europe Industrial Automation Solutions Market Study:

Based on Mode of Automation, the Fully-automatic Systems Segment is Projected to Register the Highest CAGR During the Forecast Period

The growth of this segment is driven by the growing need to increase industrial production capabilities and increasing labor costs. The companies adopting fully-automatic systems are usually large-scale companies with automated equipment in their operating facilities. They are exploring ways to minimize long-term costs by reducing human labor. Adopting fully-automatic systems helps companies increase their throughput volumes by automating the feeding and assembly processes.

In addition, several companies operating in industrial automation focus on product launches to automate industrial processes for greater efficiency. For instance, in March 2025, Beck Automation AG (Switzerland) launched the Beck Bailer. This self-operating system is set to enable the fast and fully automatic assembly of metal handles for industrial plastic pails of up to 380mm x 450mm in size. Such development contributes to the segment growth.

Based on End User, the Automotive Segment is Projected to Register the Highest CAGR During the Forecast Period

The automotive segment is projected to register the highest CAGR during the forecast period. The growth of this segment is driven by the increasing implementation of machine vision systems and sensor technologies by automotive manufacturers, increasing utilization of robotics for automotive body assembly automation, including streamlining repetitive processes like welding, material handling, and assembling auto body components, and intelligent automation for enhanced manufacturing flexibility. Automotive manufacturers can save on labor costs and rework, improving quality and repeatability with robotics, vision, and software integration.

Companies are emphasizing product development to support the growing automation in the food & beverage industry. For instance, in June 2025, ABB Ltd (Switzerland) launched four new models and 22 variants, offering more choice, increased coverage, and greater performance. The next generation models include the IRB 6710, IRB 6720, IRB 6730, and IRB 6740, suitable for payloads ranging from 150kg to 310kg, with a reach from 2.5m to 3.2m, for customers in automotive, EV, and a wide range of sectors.

Italy: The Fastest-growing Country-level Market

Italy is also projected to register the highest CAGR during the forecast period. The growth of this region is driven by the increasing need for strengthening the manufacturing sector, the growing Industrial Internet of Things (IIoT) and data collection for better management of products, the increasing number of SMEs, growing demand for automated systems for logistics, and increasing demand for product tracking, flexibility, and improved product lines.

Key Players

Some of the key players operating in the Europe industrial automation market are ABB Ltd. (Switzerland), Rockwell Automation Inc. (U.S.), Siemens AG (Germany), Yaskawa Electric Corporation (Japan), Schneider Electric SE (France), Yokogawa Electric Corporation (Japan), KUKA AG (Germany), Emerson Electric Co. (U.S.), FANUC CORPORATION (Japan), Honeywell International Inc. (U.S.), Mitsubishi Electric Corporation (Japan), OMRON Corporation (Japan), Advantech Co., Ltd. (Taiwan), Fuji Electric Co., Ltd. (Japan), and General Electric Company (U.S.).

Scope of the Report:

Europe Industrial Automation Solutions Market Assessment, by Component

Europe Industrial Automation Solutions Market Assessment, by Mode of Automation

Europe Industrial Automation Solutions Market Assessment, by End User

Europe Industrial Automation Solutions Market Assessment, by Country/Region

Key questions answered in the report:

The Europe industrial automation market is projected to reach $103.64 billion by 2032, at a CAGR of 8.5% during the forecast period.

The plant-level controls segment is expected to grow with the highest CAGR during the forecasted period.

The fully-automatic systems segment is expected to grow with the highest CAGR during the forecasted period.

The growth of this market is driven by the growing adoption of robots in the manufacturing sector, government initiatives to promote industrial automation, high labor costs in Europe, growing demand for safe and digitized production processes, and increasing investments in transforming conventional production facilities

The key players operating in the Europe industrial automation market are ABB Ltd. (Switzerland), Rockwell Automation Inc. (U.S.), Siemens AG (Germany), Yaskawa Electric Corporation (Japan), Schneider Electric SE (France), Yokogawa Electric Corporation (Japan), KUKA AG (Germany), Emerson Electric Co. (U.S.), FANUC CORPORATION (Japan), Honeywell International Inc. (U.S.), Mitsubishi Electric Corporation (Japan), OMRON Corporation (Japan), Advantech Co., Ltd. (Taiwan), Fuji Electric Co., Ltd. (Japan), and General Electric Company (U.S.).

Italy is projected to register the highest CAGR during the forecast period and offer significant growth opportunities for market players.

Published Date: May-2025

Published Date: Jan-2025

Published Date: Jan-2025

Published Date: Sep-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates