Resources

About Us

Electric Vehicle Adhesives Market by Vehicle Type (Electric Trucks, Electric Buses, Electric Bikes, Electric Cars), Resin (Epoxy, Silicon, Polyurethane, Acrylics, Others), Application, Form, Substrate, End Use and Geography - Global Forecast to 2032

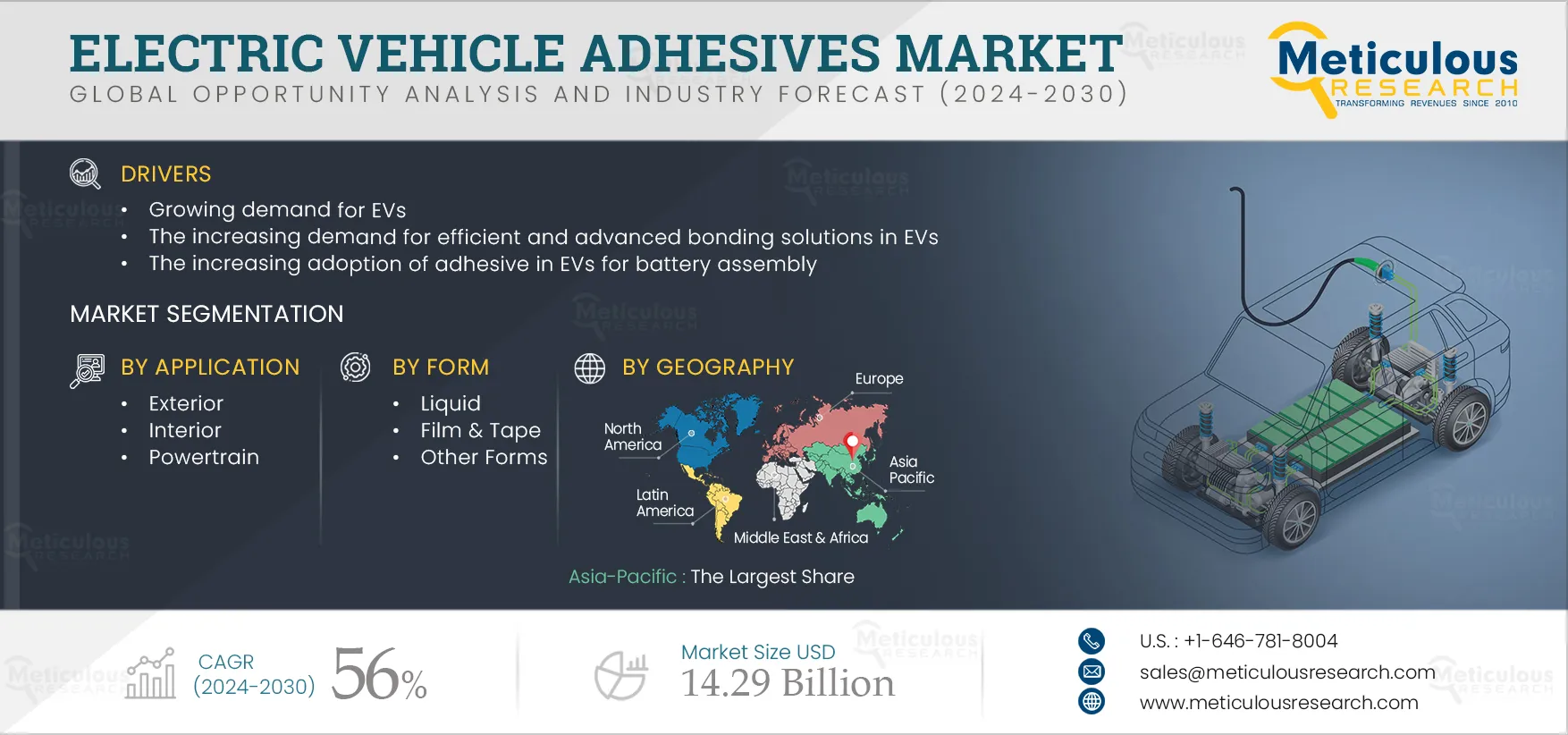

Report ID: MRCHM - 104849 Pages: 300 Jan-2025 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe Electric Vehicle Adhesives Market is projected to reach $14.29 billion by 2032, at a CAGR of 56% from 2025 to 2032. The growth of the electric vehicle adhesives market is attributed to the growing demand for EVs, the increasing demand for efficient and advanced bonding solutions in EVs, and the increasing adoption of adhesives in EVs for battery assembly. Also, the increasing demand for sustainable and eco-friendly adhesives solutions and the adoption of autonomous electric vehicles are expected to offer significant growth opportunities for players in the electric vehicle adhesives. However, the availability of mechanical fasteners may hinder the growth of this market.

The rising demand for electric vehicles (EVs) has spurred the need for efficient and advanced bonding solutions in the industry. As EV manufacturers strive to enhance vehicle performance, durability, and safety, the role of effective bonding solutions becomes crucial.

One key aspect driving the demand for advanced bonding solutions is the unique construction of EVs. Electric vehicles often feature lightweight materials, such as composites and aluminum, to maximize energy efficiency and extend driving range. These materials require specialized bonding solutions that can securely join different components while maintaining structural integrity. Advanced adhesivess with strong bonding capabilities and compatibility with a wide range of materials are essential in achieving robust and lightweight EV designs.

Additionally, EVs require efficient thermal management due to the high energy densities and power outputs of their battery systems. Thermal interface bonding plays a vital role in ensuring optimal heat transfer and dissipation, preventing overheating, and maintaining battery performance. adhesivess with excellent thermal conductivity properties are needed to create reliable bonds between heat-generating components and cooling elements, such as heat sinks and thermal pads.

The demand for advanced bonding solutions is also driven by the need for improved safety and reliability in EVs. Bonding solutions play a critical role in ensuring the structural integrity of battery modules and packs, as well as other key components. Strong and durable bonds are necessary to withstand various operating conditions, including high mechanical stress, vibration, and temperature variations. Advanced adhesivess that offer exceptional bonding strength, impact resistance, and durability are vital to ensure the long-term reliability and safety of EVs.

Moreover, the transition to electric mobility has prompted the development of innovative vehicle designs and manufacturing processes. EV manufacturers are exploring new approaches, such as multi-material constructions and modular assembly, to optimize vehicle performance and production efficiency. Advanced bonding solutions that adapt to these evolving design and manufacturing techniques are essential to enable efficient and seamless assembly processes, reduce production cycle times, and enhance overall productivity.

The demand for efficient and advanced bonding solutions in the EV industry is driven by the pursuit of improved performance, lightweight design, thermal management, safety, and manufacturing efficiency. adhesives manufacturers and suppliers are continually innovating and developing new formulations to meet these evolving demands, ensuring that electric vehicles can achieve their full potential as sustainable and technologically advanced transportation solutions.

Click here to: Get a Free Sample Copy of this report

In 2025, the Electric Cars Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on vehicle type, the electric vehicle adhesives market is segmented into electric trucks, electric buses, electric bikes, and electric cars. In 2025, the electric cars segment is expected to account for the largest share of the electric vehicle adhesives market. The large market share of this segment is attributed to the increasing adoption of electric cars, contributing to the growth of the adhesives market. The increasing need to use lightweight materials in electric vehicles, the increased requirement for efficient electrical insulation, and the need to prevent critical vehicle components from oxidizing and dielectric corrosions. adhesives manufacturers are adapting to these evolving requirements and developing specialized products to cater to the electric car industry's needs.

In 2025, the Powertrain Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on application, the electric vehicle adhesivess market is segmented into exterior, interior and powertrain. In 2025, the powertrain segment is expected to account for the largest share of the electric vehicle adhesives market. The powertrain of electric vehicles is continuously evolving with the integration of various new electrical and electronic components. There is an increased need for efficient thermal and electrical insulation adhesivess in the powertrain to protect the system's integrity. Moreover, the growing need for compact and more efficient battery packs requires the tight stacking of battery cells within the module. This may increase the temperature within the battery module, which needs to be dissipated quickly. This is done using thermally conductive adhesivess, thus driving the demand for adhesivess for electric vehicles.

In 2025, the Epoxy Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on resin, the electric vehicle adhesivess market is segmented into epoxy, silicon, polyurethane, acrylic, and other resins. In 2025, the epoxy segment is expected to account for the largest share of the electric vehicle adhesives market. The large market share of this segment is attributed to its bonding strength, durability, and resistance to chemicals and temperature fluctuations. Epoxy adhesivess are commonly used in pack and module bonding, motor assembly, and structural bonding in EVs. Their strong mechanical properties and reliability make them suitable for demanding EV applications, contributing to their largest market share.

In 2025, the Liquid Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on form, the electric vehicle adhesives market is segmented into liquid, film & tape, and other forms. In 2025, the liquid segment is expected to account for the largest share of the electric vehicle adhesives market. The large market share of this segment is attributed to the growing need for various applications across the EV manufacturing process. The large market share of this segment is attributed to its advantages, such as ease of application, adaptability to different surfaces and geometries, and strong bonding properties. Liquid adhesivess are commonly utilized in battery assembly, motor assembly, sealing, and general component bonding in EVs.

In 2025, the Plastic Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on substrate, the electric vehicle adhesives market is segmented into plastic, composite, metals, and other substrates. In 2025, the plastic segment is expected to account for the larger share of the electric vehicle adhesives market. The large market share of this segment is attributed to various EV components made with plastic or carbon fiber materials due to their lightweight, versatility, and cost-effectiveness. These are commonly employed in interior trims, exterior body panels, battery enclosures, and other non-structural parts. adhesivess are crucial in bonding plastic components, providing strength and structural integrity. Plastic adhesivess are formulated to bond different types of plastics, offering excellent adhesion and durability.

In 2025, the Pack & Module Bonding Segment is Expected to Dominate the Electric Vehicle Adhesives Market

Based on end use, the electric vehicle adhesives market is segmented into pack & module bonding, thermal interface bonding, battery cell encapsulation, and other end uses. In 2025, the pack & module bonding segment is expected to account for the largest share of the electric vehicle adhesives market. The large market share of this segment is attributed to its applications in securing and assembling the battery modules and packs in an electric vehicle. adhesivess are used to bond the individual battery cells together, provide mechanical support, and create a stable and robust battery pack structure. Furthermore, the growing demand for electric vehicles and the increasing need for high-performance, compact, and reliable battery systems also contributed to the significant market share of this segment.

In 2025, Asia-Pacific is Expected to Dominate the Electric Vehicle Adhesives Market

Based on geography, the electric vehicle adhesives market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of the electric vehicle adhesives market. Asia-Pacific is the fastest-growing market for electric vehicles. Countries like China, Japan, and South Korea have seen significant adoption of EVs, driven by government incentives, supportive policies, and a strong focus on reducing carbon emissions. The surge in EV production and sales directly translates to a higher demand for EV adhesivess. Asia-Pacific is a major manufacturing hub for the automotive industry, including electric vehicles. Many leading EV manufacturers and suppliers have production facilities in countries like China and Japan. These facilities require a substantial supply of adhesivess for various EV components, creating a robust market for EV adhesivess in the region.

Key Players:

The key players operating in the electric vehicle adhesives market are Henkel AG & Co. KGaA (Germany), H.B. Fuller Company (US), Sika AG (Switzerland), Ashland Inc. (US), PPG Industries, Inc. (US), Permabond Engineering adhesivess Ltd (UK), 3M Company (US), Wacker Chemie AG (Germany), Bostik SA – An Arkema company (France), L&L Products, Inc. (US), Jowat SE (Germany), Illinois Tools Works Inc. (U.S.), and Dymax Corporation (US).

Scope of the Report

Electric Vehicle Adhesivess Market, by Vehicle Type

Electric Vehicle Adhesives Market, by Application

Electric Vehicle Adhesives Market, by Resin

Electric Vehicle Adhesives Market, by Form

Electric Vehicle Adhesives Market, by Substrate

Electric Vehicle Adhesives Market, by End Use

Electric Vehicle Adhesives Market, by Geography

Key Questions Answered in the Report:

The report segments the electric vehicle adhesives market based on vehicles, applications, resin, deployment, form, substrate, end use, and geography. The study also evaluates industry competitors and analyzes the market at the regional and country levels.

The Electric Vehicle Adhesives Market is projected to reach $14.29 billion by 2032, at a CAGR of 56% from 2025 to 2032.

Based on vehicle type, in 2025, the electric cars segment is expected to account for the largest share of the Electric Vehicle Adhesives market.

Based on application, in 2025, the powertrain segment is expected to account for the largest share of the Electric Vehicle Adhesives market.

Based on resin, in 2025, the epoxy segment is expected to account for the largest share of the Electric Vehicle Adhesives Market.

Based on form, in 2025, the liquid segment is expected to account for the largest share of the electric vehicle adhesives market.

Based on substrate, in 2025, the plastic segment is expected to account for the largest share of the electric vehicle adhesive market.

Based on end-use, in 2025, the pack & module bonding segment is expected to account for the largest share of the electric vehicle adhesives market.

The growing demand for EVs, the increasing demand for efficient and advanced bonding solutions in EVs, and the increasing adoption of adhesive in EVs for battery assembly are key factors supporting the growth of the electric vehicle adhesive market. Also, the increasing demand for sustainable and eco-friendly adhesive solutions and the adoption of autonomous electric vehicles are expected to offer significant growth opportunities for players in the electric vehicle adhesive market.

The key players operating in the electric vehicle adhesives market are Henkel AG & Co. KGaA (Germany), H.B. Fuller Company (US), Sika AG (Switzerland), Ashland Inc. (US), PPG Industries, Inc. (US), Permabond Engineering Adhesives Ltd (UK), 3M Company (US), Wacker Chemie AG (Germany), Bostik SA – An Arkema company (France), L&L Products, Inc. (US), Jowat SE (Germany), Illinois Tools Works Inc. (U.S.), and Dymax Corporation (US).

In 2025, Asia-Pacific is expected to account for the largest share of the electric vehicle adhesives market. Asia-Pacific is the fastest-growing market for electric vehicles. Countries like China, Japan, and South Korea have seen significant adoption of EVs, driven by government incentives, supportive policies, and a strong focus on reducing carbon emissions. The surge in EV production and sales directly translates to a higher demand for EV adhesives. Asia-Pacific is a major manufacturing hub for the automotive industry, including electric vehicles. Many leading EV manufacturers and suppliers have production facilities in countries like China and Japan. These facilities require a substantial supply of adhesives for various EV components, creating a robust market for EV adhesives in the region.

1. Market Definition & Scope

1.1 Market Definition

1.2 Market Ecosystem

1.3 Currency and Limitations

1.4 Key Stakeholders

2. Research Methodology

2.1 Research Process

2.2 Data Collection & Validation

2.2.1 Secondary Research

2.2.2 Primary Research

2.3 Market Assessment

2.3.1 Market Estimation

2.3.2 Growth Forecast

3. Executive Summary

4. Market Insights

4.1 Overview

4.2 Factors Affecting Market Growth

4.2.1 Impact Analysis of Market Drivers, Restraints, Opportunities, and Challenges

4.3 Case Studies

4.4 Value Chain Analysis

5 Electric Vehicle Adhesives Market Assessment—by Vehicle Type

5.1 Overview

5.2 Electric Trucks

5.3 Electric Buses

5.4 Electric Bikes

5.5 Electric Cars

6. Electric Vehicle Adhesives Market Assessment—by Application

6.1 Introduction

6.2 Exterior

6.3 Interior

6.4 Powertrain

7. Electric Vehicle Adhesives Market Assessment—by Resin

7.1 Overview

7.2 Epoxy

7.3 Silicon

7.4 Polyurethane

7.5 Acrylic

7.6 Other Resins

8. Electric Vehicle Adhesives Market Assessment—by Form

8.1 Overview

8.2 Liquid

8.3 Film & Tape

8.4 Other Forms

9. Electric Vehicle Adhesives Market Assessment—by Substrate

9.1 Overview

9.2 Plastic

9.3 Composite

9.4 Metals

9.5 Other Substrates

10. Electric Vehicle Adhesives Market Assessment—by End Use

10.1 Overview

10.2 Pack & Module Bonding

10.3 Thermal Interface Bonding

10.4 Battery Cell Encapsulation

10.5 Other End Uses

11. Electric Vehicle Adhesives Market Assessment—by Geography

11.1 Overview

11.2 North America

11.2.1 U.S.

11.2.2 Canada

11.3 Europe

11.3.1 U.K.

11.3.2 Germany

11.3.3 France

11.3.4 Italy

11.3.5 Spain

11.3.6 Rest of Europe

11.4 Asia-Pacific

11.4.1 China

11.4.2 Japan

11.4.3 India

11.4.4 Australia

11.4.5 Indonesia

11.4.6 Malaysia

11.4.7 Rest of Asia-Pacific

11.5 Latin America

11.6 Middle East & Africa

12. Competition Analysis

12.1 Overview

12.2 Key Growth Strategies

12.2.1 Market Differentiators

12.2.2 Synergy Analysis: Major Deals & Strategic Alliances

12.3 Competitive Dashboard

12.3.1 Industry Leaders

12.3.2 Market Differentiators

12.3.3 Vanguards

12.3.4 Emerging Companies

12.4 Vendor Market Positioning

12.5 Market Share Analysis (2022)

13. Company Profiles (Company Overview, Financial Overview, Product Portfolio, and Strategic Developments)

13.1 Henkel AG & Co. KGaA

13.2 H.B. Fuller Company

13.3 Sika AG

13.4 Ashland, Inc.

13.5 PPG Industries, Inc.

13.6 Permabond Engineering Adhesives Ltd.

13.7 3M Company

13.8 Wacker Chemie AG

13.9 Bostik SA – An Arkema company

13.10 L&L Products, Inc.

13.11 Jowat SE

13.12 Illinois Tools Works Inc.

13.13 Dymax Corporation

14. Appendix

14.1 Related Reports

14.2 Available Customizations

List of Tables

Table 1 Global Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 2 Global Electric Vehicle Adhesives for Electric Trucks Market, by Country/Region, 2021–2032 (USD Million)

Table 3 Global Electric Vehicle Adhesives for Electric Buses Market, by Country/Region, 2021–2032 (USD Million)

Table 4 Global Electric Vehicle Adhesives for Electric Bikes Market, by Country/Region, 2021–2032 (USD Million)

Table 5 Global Electric Vehicle Adhesives for Electric Cars Market, by Country/Region, 2021–2032 (USD Million)

Table 6 Global Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 7 Global Electric Vehicle Adhesives Market for Exterior, by Country/Region, 2021–2032 (USD Million)

Table 8 Global Electric Vehicle Adhesives Market for Interior, by Country/Region, 2021–2032 (USD Million)

Table 9 Global Electric Vehicle Adhesives Market for Powertrain, by Country/Region, 2021–2032 (USD Million)

Table 10 Global Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 11 Global Epoxy Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 12 Global Silicon Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 13 Global Polyurethane Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 14 Global Acrylic Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 15 Global Other Resin Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 16 Global Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 17 Global Film & Tape Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 18 Global Liquid Electric Vehicle Adhesives Market, by Country/Region, 2021–2032 (USD Million)

Table 19 Global Other Electric Vehicle Adhesives Forms Market, by Country/Region, 2021–2032 (USD Million)

Table 20 Global Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 21 Global Electric Vehicle Adhesives Market for Plastic, by Country/Region, 2021–2032 (USD Million)

Table 22 Global Electric Vehicle Adhesives Market for Composite, by Country/Region, 2021–2032 (USD Million)

Table 23 Global Electric Vehicle Adhesives Market for Metal, by Country/Region, 2021–2032 (USD Million)

Table 24 Global Electric Vehicle Adhesives Market for Other Substrates, by Country/Region, 2021–2032 (USD Million)

Table 25 Global Electric Vehicle Adhesives Market, by End Uses, 2021–2032 (USD Million)

Table 26 Global Electric Vehicle Adhesives Market for Pack and Module Bonding, by Country/Region, 2021–2032 (USD Million)

Table 27 Global Electric Vehicle Adhesives Market for Thermal Interface Bonding, by Country/Region, 2021–2032 (USD Million)

Table 28 Global Electric Vehicle Adhesives Market for Battery Cell Encapsulation, by Country/Region, 2021–2032 (USD Million)

Table 29 Global Electric Vehicle Adhesives Market for Other End Uses, by Country/Region, 2021–2032 (USD Million)

Table 30 North America: Electric Vehicle Adhesives Market, by Country, 2021–2032 (USD Million)

Table 31 North America: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 32 North America: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 33 North America: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 34 North America: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 35 North America: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 36 North America: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 37 U.S.: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 38 U.S.: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 39 U.S.: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 40 U.S.: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 41 U.S.: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 42 U.S.: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 43 Canada: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 44 Canada: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 45 Canada: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 46 Canada: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 47 Canada: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 48 Canada: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 49 Europe: Electric Vehicle Adhesives Market, by Country, 2021–2032 (USD Million)

Table 50 Europe: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 51 Europe: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 52 Europe: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 53 Europe: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 54 Europe: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 55 Europe: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 56 U.K.: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 57 U.K.: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 58 U.K.: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 59 U.K.: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 60 U.K.: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 61 U.K.: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 62 Germany: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 63 Germany: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 64 Germany: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 65 Germany: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 66 Germany: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 67 Germany: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 68 France: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 69 France: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 70 France: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 71 France: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 72 France: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 73 France: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 74 Italy: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 75 Italy: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 76 Italy: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 77 Italy: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 78 Italy: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 79 Italy: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 80 Spain: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 81 Spain: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 82 Spain: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 83 Spain: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 84 Spain: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 85 Spain: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 86 Rest of Europe: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 87 Rest of Europe: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 88 Rest of Europe: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 89 Rest of Europe: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 90 Rest of Europe: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 91 Rest of Europe: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 92 Asia-Pacific: Electric Vehicle Adhesives Market, by Country, 2021–2032 (USD Million)

Table 93 Asia-Pacific: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 94 Asia-Pacific: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 95 Asia-Pacific: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 96 Asia-Pacific: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 97 Asia-Pacific: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 98 Asia-Pacific: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 99 China: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 100 China: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 101 China: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 102 China: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 103 China: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 104 China: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 105 Japan: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 106 Japan: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 107 Japan: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 108 Japan: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 109 Japan: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 110 Japan: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 111 India: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 112 India: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 113 India: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 114 India: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 115 India: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 116 India: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 117 Australia: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 118 Australia: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 119 Australia: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 120 Australia: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 121 Australia: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 122 Australia: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 123 Indonesia: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 124 Indonesia: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 125 Indonesia: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 126 Indonesia: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 127 Indonesia: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 128 Indonesia: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 129 Malaysia: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 130 Malaysia: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 131 Malaysia: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 132 Malaysia: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 133 Malaysia: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 134 Malaysia: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 135 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 136 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 137 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 138 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 139 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 140 Rest of Asia-Pacific: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 141 Latin America: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 142 Latin America: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 143 Latin America: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 144 Latin America: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 145 Latin America: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 146 Latin America: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

Table 147 Middle East & Africa: Electric Vehicle Adhesives Market, by Vehicle Type, 2021–2032 (USD Million)

Table 148 Middle East & Africa: Electric Vehicle Adhesives Market, by Application, 2021–2032 (USD Million)

Table 149 Middle East & Africa: Electric Vehicle Adhesives Market, by Resin, 2021–2032 (USD Million)

Table 150 Middle East & Africa: Electric Vehicle Adhesives Market, by Form, 2021–2032 (USD Million)

Table 151 Middle East & Africa: Electric Vehicle Adhesives Market, by Substrate, 2021–2032 (USD Million)

Table 152 Middle East & Africa: Electric Vehicle Adhesives Market, by End Use, 2021–2032 (USD Million)

List of Figures

Figure 1 Currency and Limitations

Figure 2 Research Process

Figure 3 Key Secondary Sources

Figure 4 Primary Research Techniques

Figure 5 Key Executives Interviewed

Figure 6 Market Size Estimation

Figure 7 Key Insights

Figure 8 Electric Vehicle Adhesives Market, by Vehicle Type, 2025 Vs. 2032 (USD Million)

Figure 9 Electric Vehicle Adhesives Market, by Application, 2025 Vs. 2032 (USD Million)

Figure 10 Electric Vehicle Adhesives Market, by Resin, 2025 Vs. 2032 (USD Million)

Figure 11 Electric Vehicle Adhesives Market, by Form, 2025 Vs. 2032 (USD Million)

Figure 12 Electric Vehicle Adhesives Market, by Substrate, 2025 Vs. 2032 (USD Million)

Figure 13 Electric Vehicle Adhesives Market, by End Use, 2025 Vs. 2032 (USD Million)

Figure 14 Electric Vehicle Adhesives Market, by Geography, 2025 Vs. 2032 (USD Million)

Figure 15 Geographic Snapshot: Electric Vehicle Adhesives Market (Value Share & CAGR)

Figure 16 Porter's Five Forces Analysis

Figure 17 Electric Vehicle Adhesives Value Chain

Figure 18 Electric Vehicle Adhesives Market, by Vehicles Type, 2025 Vs. 2032 (USD Million)

Figure 19 Electric Vehicle Adhesives Market, by Application, 2025 Vs. 2032 (USD Million)

Figure 20 Electric Vehicle Adhesives Market, by Resin, 2025 Vs. 2032 (USD Million)

Figure 21 Electric Vehicle Adhesives Market, by Form, 2025 Vs. 2032 (USD Million)

Figure 22 Electric Vehicle Adhesives Market, by Substrate, 2025 Vs. 2032 (USD Million)

Figure 23 Electric Vehicle Adhesives Market, by End Use, 2025 Vs. 2032 (USD Million)

Figure 24 Electric Vehicle Adhesives Market, by Geography, 2025–2032 (USD Million)

Figure 25 Key Growth Strategies Adopted by Leading Players, 2020–2025

Figure 26 Market Share Analysis: Electric Vehicle Adhesives Market, 2021

Figure 27 Competitive Dashboard: Electric Vehicle Adhesives Market

Figure 28 Henkel AG & Co. KGaA: Financial Overview (2022)

Figure 29 H.B. Fuller Company: Financial Overview (2022)

Figure 30 Sika AG: Financial Overview (2022)

Figure 31 Ashland, Inc.:Financial Overview (2022)

Figure 32 PPG Industries, Inc.: Financial Overview (2022)

Figure 33 Permabond Engineering Adhesives Ltd: Financial Overview (2022)

Figure 34 3M Company: Financial Overview (2022)

Figure 35 Wacker Chemie AG: Financial Overview (2022)

Figure 36 Bostik SA – An Arkema Company: Financial Overview (2022)

Figure 37 L&L Products, Inc.: Financial Overview (2022)

Figure 38 Jowat SE: Financial Overview (2022)

Figure 39 Illinois Tools Works Inc.: Financial Overview (2022)

Figure 40 Dymax Corporation: Financial Overview (2022)

Published Date: Aug-2017

Published Date: May-2024

Published Date: Aug-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates