Resources

About Us

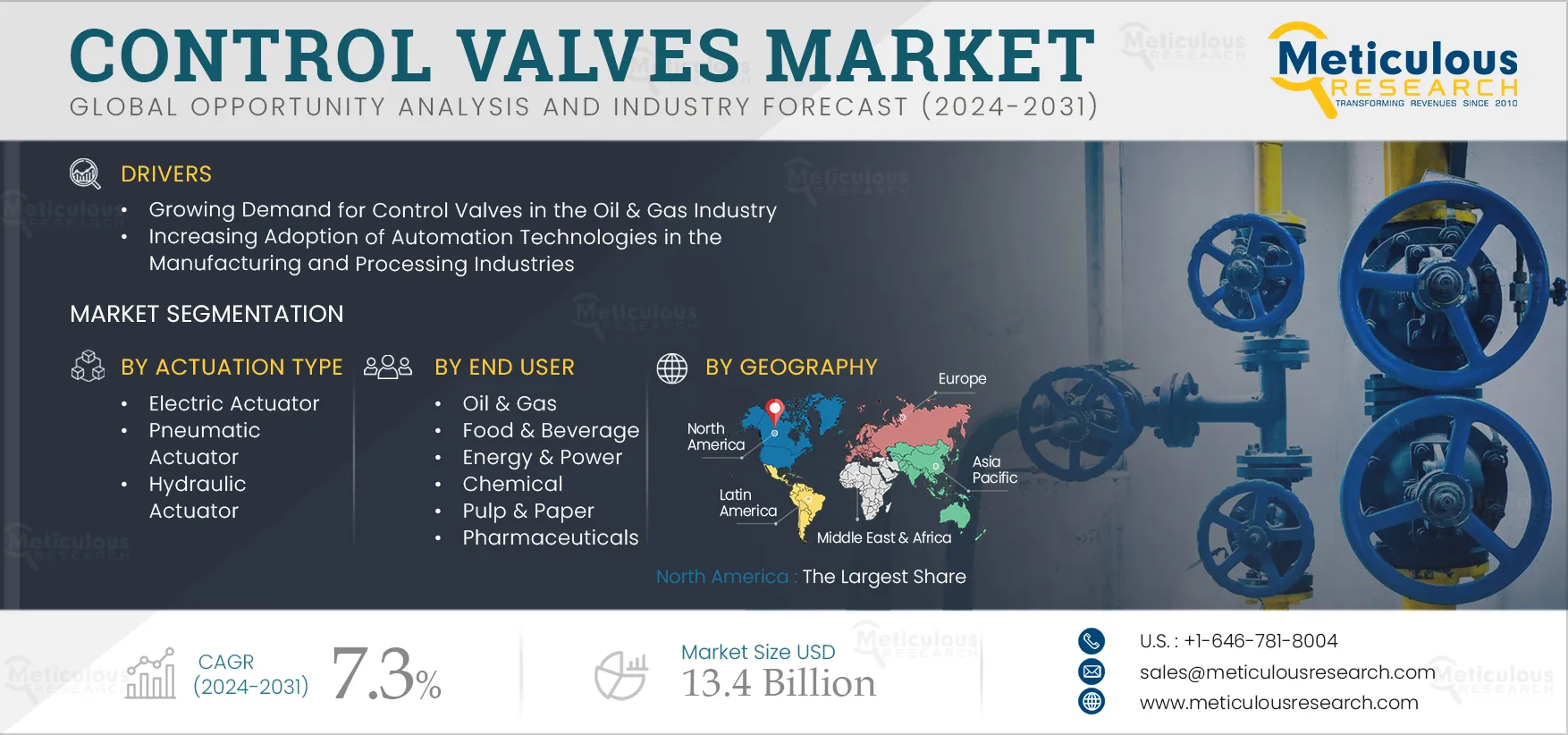

Control Valves Market by Product (Rotary Control Valves, Linear Control Valves), Actuation Type, Fluid Type (Liquid, Gas), Material, Size, End User (Oil & Gas, Water & Wastewater Treatment), Geography - Global Forecast to 2032

Report ID: MRSE - 1041380 Pages: 250 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportKey factors driving the growth of this market include the growing demand for control valves in the oil & gas industry and the increasing adoption of automation technologies in the manufacturing and processing industries. Additionally, the rising demand for customized control valves tailored to specific industry requirements and the increasing need for control valves in water & wastewater treatment are expected to create opportunities for market players.

Key Findings

Click here to: Get Free Sample Copy of this report

In recent years, technological advancements such as IoT and smart technologies are increasingly being integrated into control valves, enhancing automation and control processes. IoT-enabled control valves provide accurate, real-time data on pressure, temperature, and flow rates for effective industrial process monitoring and control. Additionally, smart technologies can alert operators to potential failures before they occur, reducing maintenance costs and downtime. The integration of machine learning (ML) and advanced analytics further improves valve performance.

Moreover, the rapid growth of the smart water technology market is prompting several companies to expand their control valve offerings to include economical, easy-to-install solutions for municipalities seeking to keep pace with the smart city movement. For instance, in June 2024, Aquana, LLC (U.S.) launched the Actuator Valve Serial (AVS), a new remote shut-off valve, as part of its Water IoT platform. Designed and manufactured in the U.S., the Aquana AVS valve is an IP68-rated remote disconnect ball valve that integrates with existing Advanced Metering Infrastructure (AMI) platforms. These developments in IoT-based and smart technology-enabled valves are expected to drive the demand for control valves during the forecast period.

In the oil & gas industry, the demand for control valves has increased due to the need for effective process management and improved safety protocols. Control valves play a crucial role in regulating flow, pressure, and temperature across various applications, from upstream extraction to downstream refining. As exploration and production operations extend into more challenging environments, the industry increasingly relies on control valves for enhanced performance and reliability. Additionally, stricter safety and environmental regulations necessitate the use of high-performance control valves to minimize risks and ensure compliance.

Moreover, rising global energy demands are driving the need for advanced control systems in extraction and processing. As the benefits and demand for control valves in the oil & gas sector grow, several companies are launching products that enable closer-to-setpoint control, easier installation, and simplified maintenance for smaller tanks. For instance, in January 2025, Emerson Electric Co. (U.S.) launched the Fisher 63EGLP-16 Pilot Operated Relief Valve, designed for installation on pressurized bullet tanks used to store liquid propane and anhydrous ammonia. Such developments in control valve technology are expected to drive market growth during the forecast period.

In water & wastewater treatment, the demand for control valves has increased to manage flow rates, pressure, and the overall efficiency of treatment processes. This sector is governed by stringent regulations that drive the need for control valves to maintain the precise conditions necessary to meet these standards. Control valves help automate processes such as chemical dosing, filtration, and disinfection. Additionally, the growing need to manage and treat pollutants in wastewater underscores the importance of precise control in treatment operations.

With a rapidly expanding population, limited natural water resources, and the challenges posed by climate change, many countries are seeking international expertise to enhance their water sustainability and treatment infrastructure. This growing initiative contributes to the increasing demand for control valves in water and wastewater treatment. For instance, in October 2025, the government of Saudi Arabia partnered with several Danish firms, including Danfoss A/S, Grundfos Holding A/S, and AVK International A/S, to manage its water resources more efficiently, reduce water wastage, and minimize environmental impact. AVK International has been providing solutions for wastewater, offering valves, hydrants, and accessories for water, gas, and sewage treatment in Jeddah. Such developments are expected to drive demand for control valves in water and wastewater treatment in the coming years.

Based on product, the global control valves market is segmented into rotary control valves and linear control valves. In 2025, the rotary control valves segment is estimated to account for the largest share of the global control valves market. The large market share of this segment is attributed to the increasing demand for rotary control valves across various industries, including oil & gas, water & wastewater treatment, and chemical processing. Factors driving this demand include their precise control over fluid flow, compact design, and advantages such as reduced operational costs and low energy consumption.

A rotary control valve regulates fluid flow within a system by utilizing rotational motion to open, close, or modulate the flow. These valves operate by turning a disk or cylindrical element within the valve body, providing precise control and enabling efficient throttling. Various types of rotary control valves are utilized across industries, including ball valves, butterfly valves, and plug valves. In sectors such as oil & gas, chemical processing, and water treatment, rotary control valves are favored for their compact design, effective sealing capabilities, and ability to handle high-pressure and high-temperature applications.

In 2025, North America is estimated to account for the largest share of the global control valves market. North America’s significant market share is primarily attributed to the increasing demand for control valves across various industries to improve productivity and process control and the presence of leading control valve manufacturers in the region.

However, the market in Asia-Pacific is projected to register the highest CAGR during the forecast period. The growth of this regional market is driven by the rapid expansion of the manufacturing and industrial sectors in countries such as China and India, the increasing demand for efficient control systems across various industries in the region, and a rising need for customized control valves tailored for specific industrial operations.

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by leading market players over the past three years (2021-2025).

The key players profiled in the global control valves market report are Emerson Electric Co. (U.S.), Siemens Corporation (Germany), Schneider Electric SE (France), Honeywell International Inc. (U.S.), KSB SE & Co. KGaA (Germany), Flowserve Corporation (U.S.), IMI plc (U.K.), Parker Hannifin Corporation (U.S.), Bray International (U.S.), Pentair plc (U.K.), Lapar Control Valve (Italy), Athena engineering S.R.L (Italy), KITZ Corporation (Japan), Christian Bürkert GmbH & Co. KG (Germany), and Curtiss-Wright Corporation (U.S.).

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

7.3% |

|

Market Size (Value) |

USD 13.4 Billion by 2032 |

|

Segments Covered |

By Product

By Actuation Type

By Fluid Type

By Material

By Size

By End User

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, Sweden, Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Singapore, Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and the Middle East & Africa (UAE, Saudi Arabia, Israel, Rest of Middle East & Africa) |

|

Key Companies |

Emerson Electric Co. (U.S.), Siemens Corporation (Germany), Schneider Electric SE (France), Honeywell International Inc. (U.S.), KSB SE & Co. KGaA (Germany), Flowserve Corporation (U.S.), IMI plc (U.K.), Parker Hannifin Corporation (U.S.), Bray International (U.S.), Pentair plc (U.K.), Lapar Control Valve (Italy), Athena engineering S.R.L (Italy), KITZ Corporation (Japan), Christian Bürkert GmbH & Co. KG (Germany), and Curtiss-Wright Corporation (U.S.) |

The global control valves market size was valued at $7.8 billion in 2024.

The market is projected to grow from $8.2 billion in 2025 to $13.4 billion by 2032.

The control valves market analysis indicates substantial growth, with projections indicating that the market will reach $13.4 billion by 2032 at a compound annual growth rate (CAGR) of 7.3% from 2025 to 2032.

The key companies operating in this market include Emerson Electric Co. (U.S.), Siemens Corporation (Germany), Schneider Electric SE (France), Honeywell International Inc. (U.S.), KSB SE & Co. KGaA (Germany), Flowserve Corporation (U.S.), IMI plc (U.K.), Parker Hannifin Corporation (U.S.), Bray International (U.S.), Pentair plc (U.K.), Lapar Control Valve (Italy), Athena engineering S.R.L (Italy), KITZ Corporation (Japan), Christian Bürkert GmbH & Co. KG (Germany), and Curtiss-Wright Corporation (U.S.).

The increasing integration of IoT and smart technologies into control valves and advancements in materials and design are prominent trends in the control valves market.

By Product, the rotary control valves segment is forecasted to hold the largest market share during 2025-2032.

By Type, the pneumatic actuator segment is expected to dominate the market during 2025-2032.

By , the liquid segment is expected to dominate the market during 2025-2032.

By , the stainless steel segment is expected to dominate the market during 2025-2032.

By , the > 6 Inch segment is expected to dominate the market during 2025-2032.

By End User, the oil & gas segment is expected to hold the largest market share during 2025-2032.

By geography, North America is anticipated to hold the major market share during 2025-2032.

By region, North America holds the largest control valves market share in 2025. However, the market in Asia-Pacific is expected to witness the highest growth rate, driven by the rapid expansion of the manufacturing and industrial sectors in countries such as China and India, the increasing demand for efficient control systems across various industries in the region, and a rising need for customized control valves tailored for specific industrial operations.

Key factors driving the growth of this market include the growing demand for control valves in the oil & gas industry and the increasing adoption of automation technologies in the manufacturing and processing industries.

Published Date: Jul-2024

Published Date: Oct-2022

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates