Resources

About Us

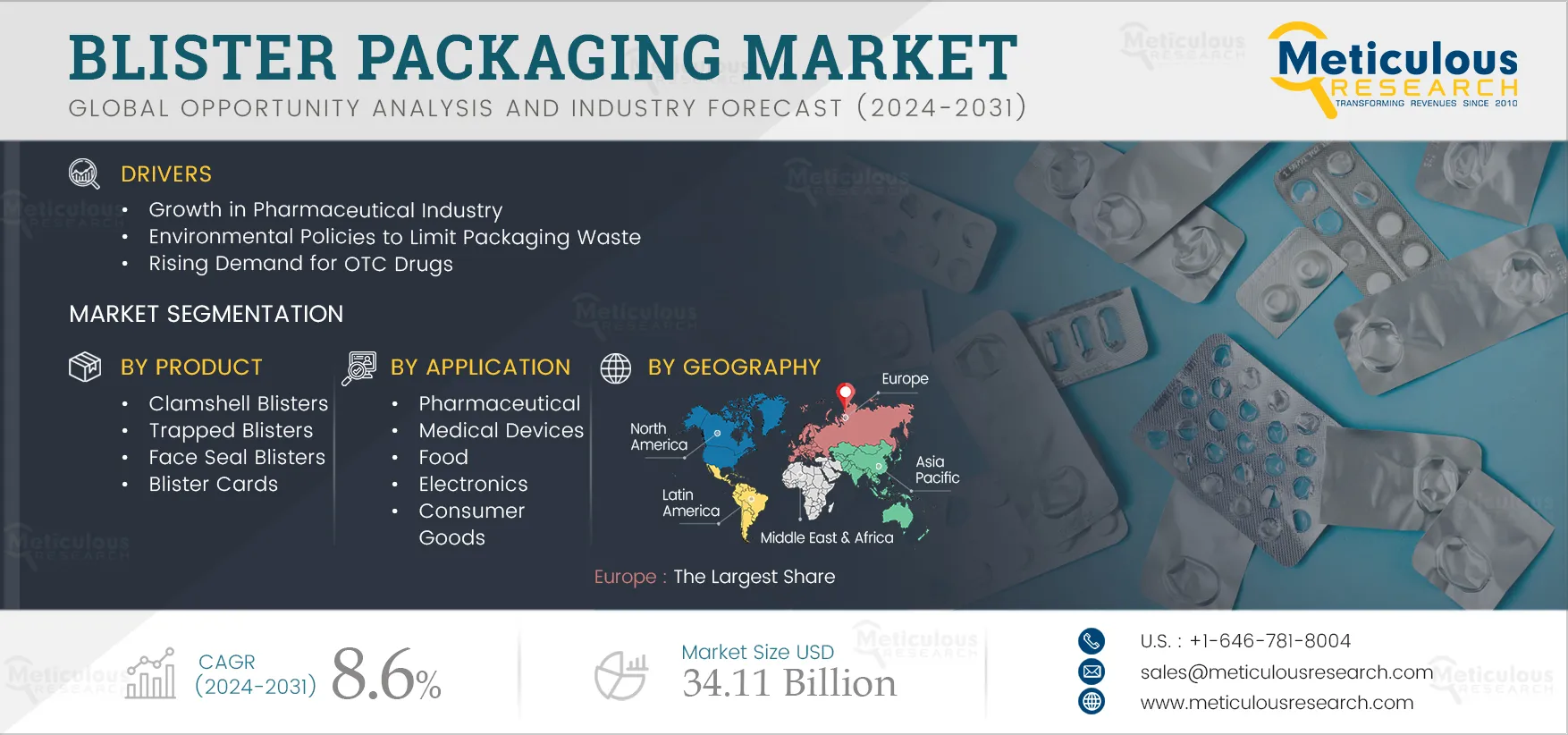

Blister Packaging Market Size, Share, Forecast, & Trends Analysis by Product (Clamshell, Trapped) Material (PP, PE, PVC, PET, Paper, Aluminum) Technology (Thermoforming, Cold Forming) Application (Pharma, Medical Device, Food) - Global Forecast to 2032

Report ID: MRHC - 1041151 Pages: 300 May-2024 Formats*: PDF Category: Healthcare Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of this market is attributed to the growth in the pharmaceutical industry, environmental policies to limit packaging waste, rising demand for OTC drugs, and rising adoption of blister packaging in food, electronics, and consumer goods. Furthermore, the shift from bottles to blister packaging, the rising number of clinical trials, and advancements in blister packaging are expected to offer growth opportunities.

The pharmaceutical industry has witnessed rapid growth over the years. According to the India Brand Equity Foundation (India), the pharmaceutical industry in India is expected to reach USD 130 billion by 2032 from USD 42 billion in 2021. The rising need for novel therapies, increasing pharmaceutical R&D expenditures, the rising prevalence of chronic diseases, and increasing funding for drug discovery are some of the factors driving the growth of the pharmaceutical industry.

In June 2024, the Commonwealth Government’s Medical Research Future Fund (MRFF) (Australia) invested USD 9.75 million in establishing MedChem Australia, a new national medicinal chemistry initiative, to accelerate the identification of early-stage drug candidates. Similarly, in July 2022, the Council of Scientific and Industrial Research (CSIR) (India) invested USD 6.73 million in R&D activities for drug discovery and development. Increasing funding for drug discovery & development is expected to accelerate the manufacturing of newer medicines, boosting the demand for pharmaceutical blister packaging.

Click here to: Get Free Sample Pages of this Report

The food & beverage industry plays a crucial role in the distribution, production, retailing, and marketing of foods consumed by millions globally. This industry has experienced exponential growth. For instance, the European food & beverage sector generated an annual turnover of USD 1.15 trillion (EUR 1.1 trillion) and USD 242 billion (EUR 230 billion) value added in 2022, making it one of the largest manufacturing industries in Europe (Source: Eurostat).

Food Blister Packaging is an excellent and efficient solution for protecting food products such as cakes, fruits, sushi, vegetables, chocolates, salads, meat, fish, and meals. Blister packs are economical and adhere to required regulatory compliance. Additionally, blister packaging protects food from airborne contaminants and keeps the food fresh and visually appealing. According to Ecobliss Retail Packaging (Netherlands), the most common type of food packaging is a blister pack.

Smart blister packaging refers to the integration of digital technologies into packaging for increased convenience, safety, and efficacy of packaged products. A variety of technologies can be used to develop smart blister packaging, including printed brand security features, Radio Frequency Identification (RFID), temperature-indicating inks, Near Field Communication (NFC), printed invisible watermarks, and battery-free Bluetooth.

The main advantage of smart pharmaceutical blister packaging is medication adherence & tracking. According to Information Mediary Corporation (Canada), a smart manufacturing company, non-adherence to prescribed medicines costs an estimated USD 300 billion per year to the U.S. healthcare system. Smart packaging helps improve medication adherence, thus driving the demand for smart pharmaceutical blister packaging.

Sustainable packaging is the use of reusable, recyclable, and biodegradable materials for packaging. The sustainable blister packaging sector is expanding due to strict laws and regulations enforced by governments of various countries and regulatory bodies. Additionally, a shift in consumer preference toward recyclable and environmentally friendly blister pack materials also propels innovations in sustainable blister packaging. The blister packaging industry is moving toward recyclable PET plastic, paper, and other environment-friendly materials to help create a more sustainable future. PET packaging can be recycled and reused. Some of the recent product launches for sustainable blister packaging are as follows:

The packaging industry is gradually shifting from bottles to blister packs. According to Amcor plc (Switzerland), in Europe, 85% of solid dosage drugs are packaged in blister packaging and 15% in bottles. Integration of adherence monitoring and ongoing R&D efforts for sustainable blister packaging alternatives are contributing to the increasing use of blister packaging compared with bottles.

Blister packaging efficiently mitigates the risk of contamination risk. In bottle packaging, the entire packaged product comes in contact with the environment and user once the seal is opened, thus raising the risk of contamination. The hermetic sealing of blister packs has been proven to prevent exposure to contamination until the time of use and maximize shelf life by preventing moisture ingress. To allow users to more readily track their dosing to maintain compliance with their prescriptions, the pharmaceutical packaging industry is shifting toward blister packaging.

Based on product, the blister packaging market is segmented into clamshell blisters, trapped blisters, face seal blisters, and blister cards. In 2025, the clamshell blisters segment is expected to account for the largest share of 46% of the blister packaging market. The high adoption of clamshell containers in the food industry for packaging food products and the shifting trend from trapped to clamshell in pharmaceuticals supports the large market share. Clamshell packaging is durable and resistant to damage. The clamshell can extend the shelf life and improve the quality of products. Furthermore, to improve the supply chain integrity in the pharmaceutical industry, manufacturers are shifting to clamshells, as the signs of tampering are easily noticeable.

Based on material, the blister packaging market is segmented into polymer, aluminum, and paper & paperboard. In 2025, the polymer segment is expected to account for the largest share of 43% of the blister packaging market. Polymers play an important role in the packaging of products. The properties of plastic packaging materials, such as controllability, permeability, flexibility, and transparency, make the material an ideal choice for packaging. Additionally, polymers are lightweight in nature which makes the material ideal for transportation by decreasing the shipping cost.

Polymers such as PET, PE, and PP are recyclable; hence, key market players are increasingly using polymers for the manufacturing of blister packaging to maintain compliance with regulatory policy, contributing to the large market share of the segment. For instance, in April 2024, SÜDPACK (Germany) launched a recyclable, mono-polypropylene blister packaging solution for the pharmaceutical, medical goods, and life science industries.

However, the paper & paperboard segment is projected to witness the highest growth rate of 8.6% during the forecast period of 2025–2032. The consumption and production of paper are increasing for packaging applications owing to its properties, such as flexibility in design, sustainability, and barrier properties. Paper packaging is relatively cheaper than other types of packaging materials, making it a cost-effective option. Paper-based laminate composites enhance the storage time of packaged products, making them suitable for packaging that requires a modified atmosphere.

Based on technology, the blister packaging market is segmented into thermoforming blister packaging and cold forming blister packaging. In 2025, the thermoforming blister packaging segment is expected to account for the largest share of 65% of the blister packaging market. The thermoforming technology majorly uses PVC material to create the blister packs. According to Ascend Packaging Systems LLC (U.S.), the cost of thermoform blister packs is less than the cold form. Thus, the cost-effectiveness of the thermoform technology is contributing to the largest share of the segment.

Additionally, thermoform blister packaging is strong, resilient, and resistant to tampering. It protects the product during transportation and provides a variety of sealing choices, depending on the packaging requirements, thus increasing the product's shelf life.

Based on application, the blister packaging market is segmented into pharmaceutical, medical devices, food, electronics, consumer goods, and other applications. In 2025, the pharmaceutical industry segment is expected to account for the largest share of 54% of the blister packaging market. The pharmaceutical segment is further segmented into tablets, capsules, and powders. The tablet segment is expected to account for the largest share of the pharmaceutical application. The largest share of the segment is attributed to the higher preference for oral solid drugs. Oral drugs are commonly packaged in blister packaging, which protects the drug from external environmental conditions, prevents contamination, and maintains drug stability. The packaging also provides precise dosing, subsequently increasing overall treatment efficiency.

The rising approval for oral drugs is further contributing to the largest share of the segment. In 2024, the U.S. FDA approved 23 oral drugs, an increase from 14 oral drugs in 2022. Additionally, the advancements in blister packaging, rising R&D expenditure by pharmaceutical companies, and facility expansions for tablets are further supporting the largest share of the segment.

However, the medical devices industry segment is projected to witness the highest growth rate of 9% during the forecast period of 2025–2032. In medical devices blister packaging is majorly used for the packaging of syringes, stents, suture kits, surgical devices, insulin pumps, and others. Blister packs maintain the sterility of devices and reduce the chances of infection to the end user. Additionally, the blister packs protect the medical devices during transportation. The rising prevalence of chronic diseases coupled with growing hospital admissions are driving the growth of blister packaging for medical and surgical devices.

In 2025, Europe is expected to account for the largest share of 37.2% of the blister packaging market. Europe’s significant market share is attributed the supportive initiatives from governments, food industry expansion, the rising market for cosmetics & personal care, companies expanding their manufacturing capacities and operations, and advancements in blister packaging capabilities. According to Amcor plc (Switzerland), in Europe, 85% of solid dosage drugs are packaged in blister packaging and 15% in packaging bottles. Additionally, pharmaceutical production in European countries is increasing, thereby driving the demand for pharmaceutical blister packaging. According to the European Federation of Pharmaceutical Industries and Associations, pharmaceutical production in Belgium increased to USD 51,231.7 million in 2021 from USD 23,123.9 million in 2020. Similarly, in Switzerland, pharmaceutical production increased to USD 70,781.4 million in 2021 from USD 60,759.5 million in 2020.

Moreover, the market in Asia-Pacific is slated to register the highest growth rate of 9.2% during the forecast period. The countries in Asia-Pacific, including China, India, and South Korea, are projected to offer significant growth opportunities for the vendors in this market. The expansion in the end-use industries such as pharmaceutical, food, consumer goods, and veterinary is driving the demand for blister packaging. For instance, in South Korea, the food market is expected to increase by 9.9% from 2022 to 2026. Similarly, the food processing sector in India is expected to reach USD 470 billion in 2025 from USD 263 BILLION IN 2021. Additionally, the countries in Asia-Pacific have long been recognized as low-cost hubs for pharmaceutical manufacturing, further bolstering market expansion.

The report offers a competitive landscape based on an extensive assessment of the product offerings and geographic presence of leading market players and the key growth strategies adopted by them over the past few years 2020–2025. The key players operating in the global blister packaging market are Amcor plc (Switzerland), AptarGroup, Inc. (U.S.), Constantia Flexibles (Austria), UFLEX LIMITED (India), Honeywell International Inc. (U.S.), Sonoco Products Company (U.S.), Tekni-Plex, Inc. (U.S.), Ecobliss Pharmaceutical Packaging (Netherlands), Rohrer Corporation (U.S.), Schreiner MediPharm L.P. (Germany), Perlen Packaging (Switzerland), and Henkel AG & Co. KGaA (Germany).

In February 2025, Catalent, Inc. (U.S.) upgraded a capsule filling of Dry Powders facility for Inhalation and capsule blistering suites in Massachusetts, U.S. The upgrade includes the addition of capacity for both development and commercial spray drying.

In January 2025, Tekni-Plex, Inc. (U.S.), in partnership with Alpek Polyester USA, LLC (U.S.), launched a pharmaceutical-grade PET blister film manufactured using post-consumer recycled (PCR) monomers.

|

Particulars |

Details |

|

Number of Pages |

300 |

|

Format |

|

|

Forecast Period |

2025-2032 |

|

Base Year |

2024 |

|

CAGR |

8.6% |

|

Estimated Market Size (Value) |

$34.11 billion by 2032 |

|

Segments Covered |

By Product

By Material

By Technology

By Application

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, France, U.K., Italy, Spain, Denmark, Ireland, Belgium, Switzerland, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, Rest of Latin America), and Middle East & Africa |

|

Key Companies |

The key players operating in the global blister packaging market are Amcor plc (Switzerland), AptarGroup, Inc. (U.S.), Constantia Flexibles (Austria), UFLEX LIMITED (India), Honeywell International Inc. (U.S.), Sonoco Products Company (U.S.), Tekni-Plex, Inc. (U.S.), Ecobliss Pharmaceutical Packaging (Netherlands), Rohrer Corporation (U.S.), Schreiner MediPharm L.P. (Germany), Perlen Packaging (Switzerland), and Henkel AG & Co. KGaA (Germany) |

The global blister packaging market report covers the qualitative analysis and market sizing of the blister packaging market for various applications across end-use industries. This report involves the analysis of various segments of blister packaging, such as product, technology, material, and application, at the regional and country levels. The report also provides insights on factors impacting market growth, regulatory analysis, pricing analysis of raw materials, value chain analysis, and Porter’s five forces analysis.

The global blister packaging market is projected to reach $34.11 billion by 2032 at a CAGR of 8.6% from 2025 to 2032.

Among all the products studied in the report, the blister card segment is expected to record the fastest CAGR over the forecast period. Blister card packaging allows customers to see whether the packaged product is in good condition. It can also be customized to make it more visually appealing, which increases the product’s perceived value and, thus, preference is increasing.

Among all the applications studied in the report, in 2025, the pharmaceutical segment is expected to account for the largest share of the blister packaging market. The pharmaceutical industry segment is further divided into tablets, powders, and capsules. In 2025, the tablets segment is expected to account for the largest share of the market. Security and safety are major factors driving the demand for blisters for tablet packaging. The increasing need for tamper-evident packaging to protect consumers throughout a drug product's life cycle is raising the demand for blister packaging.

The growth of this market can be attributed to various factors, such as the growth in the pharmaceutical industry, environmental policies to limit packaging waste, rising demand for OTC drugs, and rising adoption of blister packaging in food, electronics, and consumer goods. Furthermore, the shift from bottles to blister packaging, the rising number of clinical trials, and advancements in blister packaging are expected to offer growth opportunities.

The key players operating in the global blister packaging market are Amcor plc (Switzerland), AptarGroup, Inc. (U.S.), Constantia Flexibles (Austria), UFLEX LIMITED (India), Honeywell International Inc. (U.S.), Sonoco Products Company (U.S.), Tekni-Plex, Inc. (U.S.), Ecobliss Pharmaceutical Packaging (Netherlands), Rohrer Corporation (U.S.), Schreiner MediPharm L.P. (Germany), Perlen Packaging (Switzerland), and Henkel AG & Co. KGaA (Germany).

The countries in Asia-Pacific, including China, India, and South Korea, are projected to offer significant growth opportunities for the vendors in this market. The expansion in end-use industries such as pharmaceutical, food, consumer goods, and veterinary medicine is driving the demand for blister packaging.

Published Date: Apr-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates