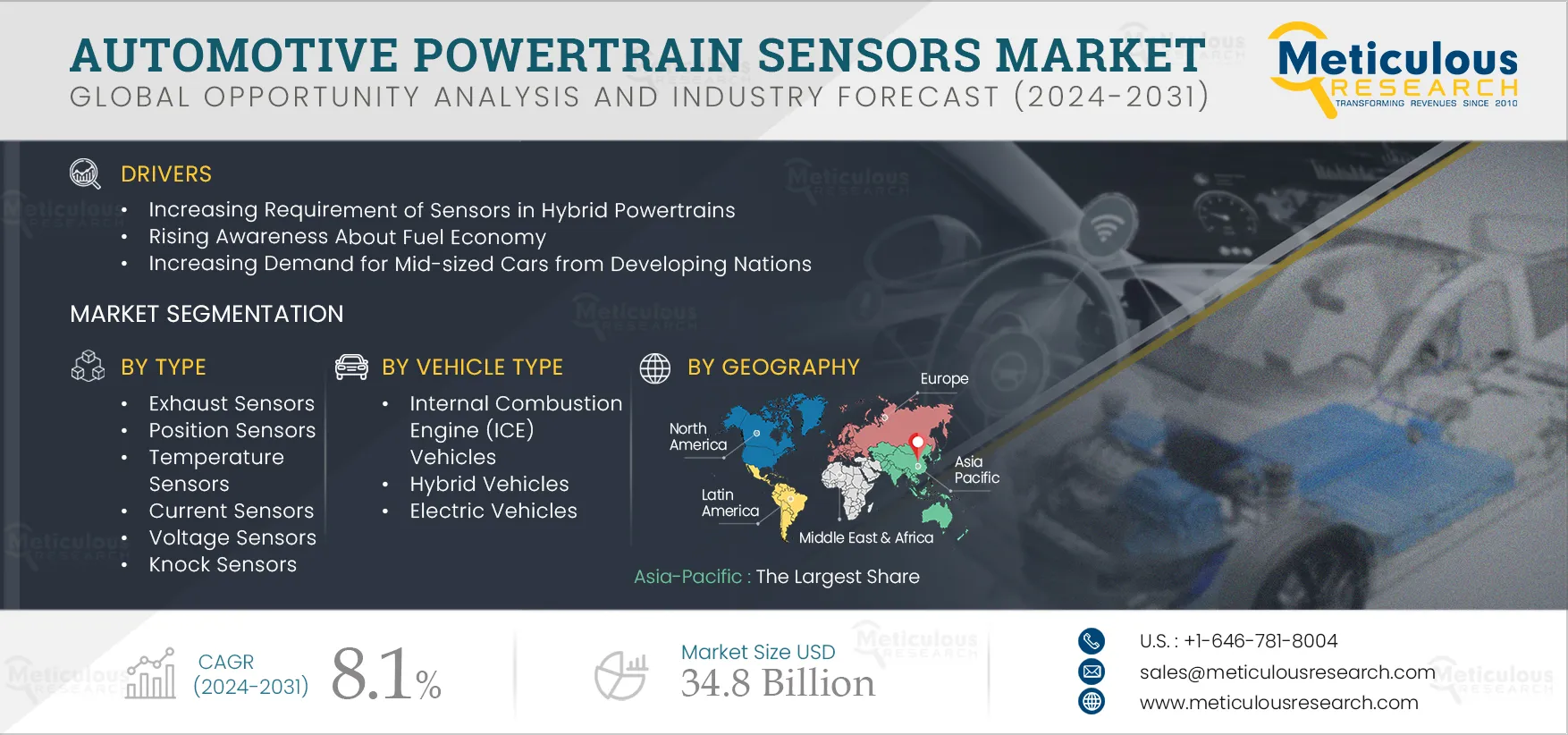

The Automotive Powertrain Sensors Market is expected to reach $34.8 billion by 2031 growing at a CAGR of 8.1% during the forecast period of 2024 to 2031. By volume, the automotive powertrain sensors market is expected to reach 5,615.2 million units by 2028 from an estimated 3,220.7 million units in 2021 at a CAGR of 8.3%. Powertrain sensors are used for monitoring various engine parameters, such as air mass, pressure, and speed, and send these data to the electronic control units to optimize vehicle performance. The efficiency of the vehicle depends on the accuracy, precision, and response time of powertrain sensors. These sensors can effectively detect the soot, NOx, and oxygen levels in the engine exhaust and help meet various emission norms and regulations worldwide.

Here are the top 10 companies operating in the Automotive Powertrain Sensors Market

ZF Friedrichshafen AG

ZF Friedrichshafen is a global technology company that supplies systems for passenger cars, commercial vehicles, and industrial technology, enabling the next generation of mobility. The company offers comprehensive solutions for vehicles manufacturer and newly emerging transport and mobility service providers. The company works in five technological domains: vehicle motion control, integrated safety, automated driving, electric mobility, and digitalization and software.

With its subsidiaries and a strong distribution network, the company has a presence across Europe, North America, Asia-Pacific, South America, and Africa.

Denso Corporation

Denso Corporation is a global automotive component manufacturing company that focuses on advanced mobility solutions. The company is a leading provider of automotive parts and systems. The company provides thermal, powertrain, mobility, electrification & electronic system to automotive OEMs and other automotive component manufacturers worldwide. Denso Corporation focuses on developing core technologies in electrification, automated driving, connected cars, and factory automation to create new value and influence the future of mobility. The company has 200 consolidated subsidiaries and has its research, production, and sales offices worldwide.

Denso Corporation caters to different industry segments, such as thermal systems, powertrain systems, electrification systems, mobility electronics, sensors and semiconductors, and non-automotive businesses. With its subsidiaries and a strong distribution network, the company has its presence across Japan, North America, Europe, Asia, and other countries.

Renesas Electronics Corporation

Renesas Electronics Corporation is a leading supplier of vehicle control microcontrollers and System-on-Chip (SoC) products for the automotive industry. Renesas Electronics Corporation’s product portfolio includes analog, power, and embedded processing. Renesas Electronics Corporation caters to various sectors, such as automotive, communication, healthcare, high-performance computing, home & building, industrial, and personal electronics. With its subsidiaries and a strong distribution network, the company has its global presence across Japan, China, Asia (excluding China), Europe, North America, and other countries. Renesas Electronics Corporation operates through three reportable segments: Automotive, Industrial/Infrastructure/IoT, and Others.

The company offers powertrain solutions through its automotive segment. The company’s offerings include microcontrollers and microprocessors, automotive products, analog products, sensor products, clock & timing, interface & connectivity, memory & logic, power & power management, RF products, and space & harsh environment.

Valeo Group

Valeo Group (Valeo) is a global automotive component supplier that supplies a wide range of products to automotive OEMs and aftermarkets. Valeo provides mobility solutions such as vehicle electrification, autonomous vehicle, digital mobility, comfort and driving assistant systems, powertrain systems, thermal systems, and visibility systems.

The company operates through four reportable segments: Comfort & Driving Assistance Systems, Powertrain Systems, Thermal Systems, and Visibility Systems. With its subsidiaries and a strong distribution network, the company has a presence across North America, Europe, China, Asia, and South America.

STMicroelectronics N.V.

STMicroelectronics N.V. is a global company that designs, develops, and manufactures electronic and semiconductor devices, including discrete and standard components. The company provides a wide range of products, including amplifiers, comparators, MEMS & sensors, ADAS devices, automotive microcontrollers, data converters, diodes, and rectifiers. The company operates through four business segments: Automotive and Discrete Group (ADG), Microcontrollers and Digital ICs Group (MDG), Analog, MEMS and Sensors Group (AMS), and Others.

The company provides a wide range of sensors and products through its MEMS and Sensors Group segment. With its subsidiaries and a strong distribution network, the company has a presence across EMEA, the Americas, and AsiaPacific.

HELLA GmbH & Co. KGaA

HELLA GmbH & Co. KGaA is an international automotive part supplier. HELLA GmbH & Co. KGaA develops and manufactures lighting and electronic components & systems for the automotive industry. The company has three reportable business segments: Automotive, Special Application, and Aftermarket. The company develops, produces, and markets lighting and electronic components systems for vehicles through its Automotive segment. The company caters to construction machinery manufacturers and aftermarket segments through its Special Application segment by producing and marketing products for independent aftermarkets and garages.

With its subsidiaries and a strong distribution network, the company has its presence across Germany, Europe, North America, Central America, South America, Asia-Pacific, and other countries.

TE Connectivity

TE Connectivity is a multinational technology company that designs and manufactures connectivity and sensors for various industries, such as automotive, industrial equipment, data communication systems, consumer electronics and energy, oil and gas, aerospace, defense, and medical. They have more than 100 manufacturing and engineering centers globally and 1,500 patents worldwide. TE Connectivity has three reportable business segments: Transportation Solutions, Industrial Solutions, and Communication Solutions. TE Connectivity provides a wide range of products, such as antennas, application tooling, cable assemblies, connectors, EMI filters, fiber optics, harnessing, heat shrinking tubing, identification & labeling, passive components, power systems, relays, contractors & switches, sensors, terminal & splices, and wire & cables.

The company manufactures 19,200 million products annually, serving customers in 140 countries worldwide. With its subsidiaries and a strong distribution network, the company has its presence across Asia-Pacific, Europe, the Middle East, Africa, and the Americas.

Mitsubishi Electric Corporation

Mitsubishi Electric Corporation is a Japanese multinational electronics and electrical equipment manufacturing company. Mitsubishi Electric Corporation has major subsidiaries in energy and electric systems, industrial automation systems, electronic devices, home appliances, information and communication systems, etc. The company offers a wide range of products and solutions, such as air conditioning systems, home products, factory automation systems, automotive equipment, building systems, energy systems, semiconductor and devices, visual information systems, transportation systems, information and communication systems, space systems, and public systems. Mitsubishi Electric Corporation operates through six business segments: Energy and Electric Systems, Industrial Automation Segment, Electronic Devices, Home Appliances, Information and Communication System, and Others Segment.

Mitsubishi Electric Corporation has various consolidated subsidiaries worldwide, including 24 in Europe, 4 in the Middle East & Africa, 64 in Asia (excluding Japan), 14 in North America, 95 in Japan, 1 in Oceania, and 1 in Central and South America. With its subsidiaries and a strong distribution network, the company has its presence across Japan, North America, Europe, Asia (excluding Japan), and other countries

Infineon Technologies AG

Infineon Technologies AG is a world leader in semiconductor solutions. Infineon Technologies AG provides a wide range of semiconductor design solutions used in sensing solutions, automotive, power management, industrial power control, and security in IoT applications. Infineon Technologies AG caters to various sectors, including automotive, communication, consumer, industrial, and security. The company operates through five reportable business segments: Automotive, Industrial Power Control, Power & Sensor Systems, Connected Secure Systems, and Other Operating Systems.

With its subsidiaries and a strong distribution network, the company has its presence across Europe, the Middle East & Africa, Asia-Pacific, Greater China, Japan, and the Americas. Infineon Technologies AG has 54 R&D locations and 21 manufacturing locations worldwide. As of September 2021, the company had a headcount of 48,591 employees globally.

CTS Corporation

CTS Corporation is a leading designer and manufacturer of actuators, sensors, and electronic components. CTS Corporation caters to various sectors, such as aerospace & defense, medical, industrial, IoT, 5G, telecom & IT, and transportation. The company operates through five reportable business segments: Transportation, Industrial, Medical, Aerospace and Defense, and Telecommunications and IT. The company offers its products through three segments: Sense, Content, and Move. The Sense segment includes controls, pedals, sensors, switches, sensors & transducers, and piezoelectric sense products; the Content segment includes EMI\RFI filters, frequency control products, RF filters, and specialty capacitors & specialty resistors; and the Move segment includes piezoelectric move products, rotary actuators, and thermal products.

The company operates in the global powertrain sensors market through its Sense segment. CTS Corporation has different consolidated subsidiaries around the world, and it has 16 manufacturing locations in North America, Asia, and Europe.

Popular Mentions: BorgWarner Inc., NXP Semiconductors N.V., Robert Bosch GmbH, Texas Instruments Incorporated, and Piezotronics, Inc.