Resources

About Us

Automotive 3D Printing Market Size, Share, Forecast, & Trends Analysis by Offering (Hardware, Services), Technology (Fused Deposition Modeling, Stereo Lithography), Component (Interior, Exterior), Vehicle Types, Application, Geography - Global Forecast to 2032

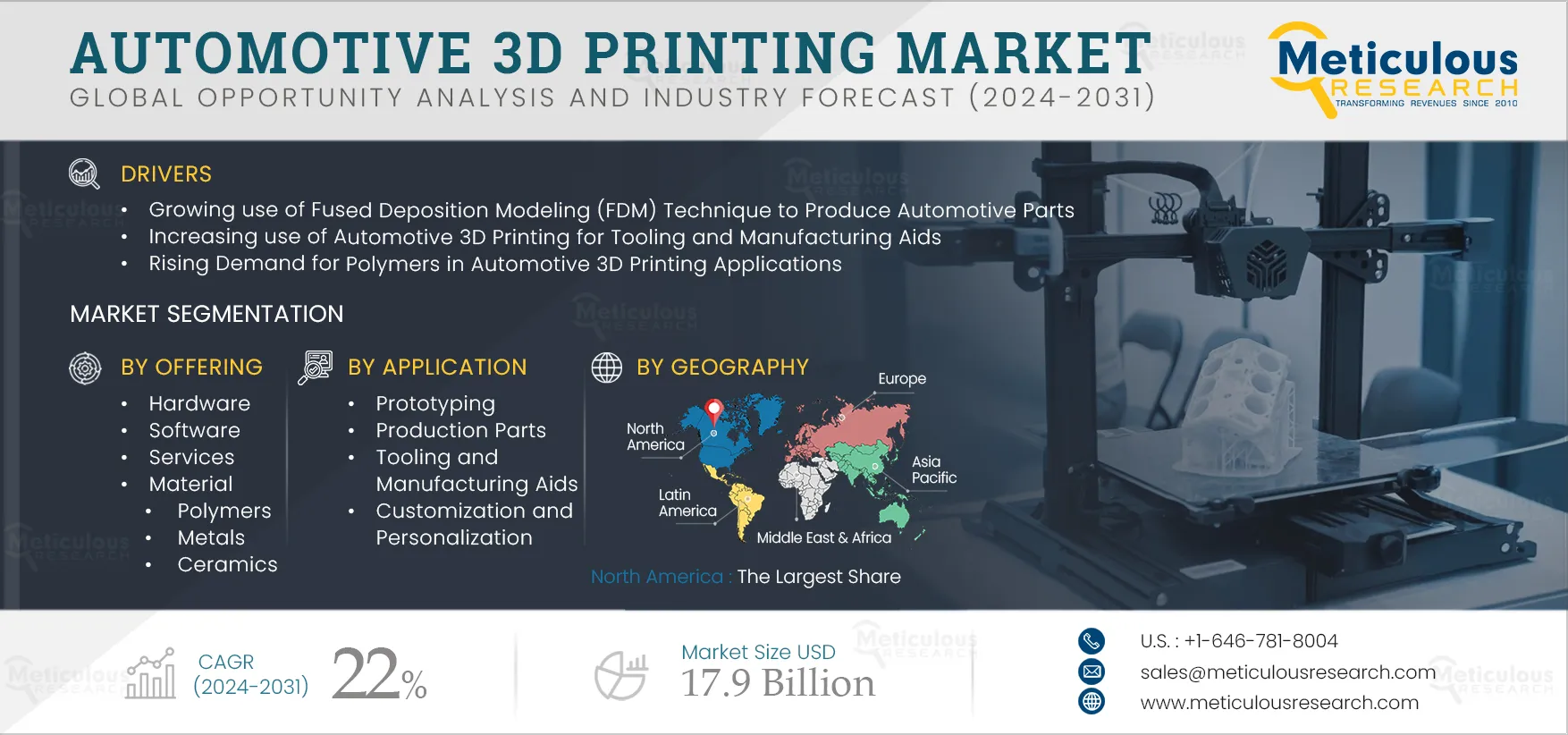

Report ID: MRSE - 1041355 Pages: 300 Oct-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportThe growth of this market is driven by the growing use of the fused deposition modeling (FDM) technique to produce automotive parts, the Increasing use of 3D printing for tooling and manufacturing aids, and the rising demand for polymers in automotive 3D printing applications. Furthermore, rising customer preference for customized and personalized automotive parts and government initiatives supporting the adoption of 3D printing technologies are expected to generate growth opportunities for the stakeholders in this market.

Key Findings

Click here to: Get Free Sample Pages of this Report

Artificial intelligence (AI) is rapidly emerging as one of the fastest-growing technologies in automotive 3D printing. Its integration enables designers to analyze vast amounts of data, identify design flaws, and propose enhancements, thereby streamlining the design process. AI also facilitates the creation of more personalized products by predicting user preferences. Furthermore, incorporating AI into automotive 3D printing allows for the optimization of object structures, resulting in components that are either stronger or lighter for vehicles.

Moreover, AI-enabled 3D printers can detect and correct errors before they occur, enhancing the overall efficiency of the printing process. Several companies are introducing AI-based 3D printers to streamline and automate the entire end-to-end workflow. For example, in November 2024, Nexa3D launched the Nexa AI platform for its XiP Pro Industrial 3D Printer. This innovative software leverages artificial intelligence and machine learning to transform the 3D printing user experience, simplifying and automating everything from file preparation to post-processing. Such advancements in AI integration within 3D printers are expected to drive demand for automotive 3D printing during the forecast period.

In automotive 3D printing, the demand for polymers has risen significantly due to the need for lighter, stronger, and more efficient materials for manufacturing parts. Many automotive OEMs are increasingly incorporating polymer materials into their products because of their lightweight nature, flexibility, and toughness. Polymers help reduce vehicle weight without sacrificing structural integrity, resulting in durable parts that enhance fuel efficiency and overall vehicle performance. Their strength and lightweight characteristics make polymers particularly suitable for critical automotive components produced through 3D printing.

Furthermore, polymers for 3D printing are increasingly being used to create jigs, fixtures, and tooling more efficiently than traditional manufacturing materials. Several companies are introducing polymers specifically designed for automotive 3D printing, focusing on attributes like high strength, heat resistance, and surface smoothness. For example, in August 2024, Toray Industries, Inc. (Japan) launched the ToraypearlPA6 Polymer, which offers exceptional strength, thermal resistance, and quality for 3D printing. Toray plans to utilize these features to develop prototypes for automotive parts, power tools, and other applications that require high durability, heat resistance, and precision. Such advancements in polymer materials for 3D printing are expected to drive growth in this market during the forecast period.

In the automotive sector, the demand for customized and personalized parts is significantly driving the growth of automotive 3D printing. Manufacturers are responding to customer preferences by leveraging 3D printing to enhance the car experience and explore new avenues for innovation. As consumer demand rises for modifications, such as custom exhaust systems, suspension enhancements, and specialized engine components, 3D printing techniques facilitate easier and more cost-effective customization of parts. This capability is encouraging automotive manufacturers to expand their offerings and meet the evolving needs of their customers.

Additionally, 3D printing empowers automotive manufacturers to provide bespoke solutions, ranging from custom interiors to limited-edition vehicles. This capability enables companies to more effectively meet customer demands while gaining a competitive advantage in the market. By utilizing 3D printing, manufacturers can streamline the entire production cycle, from design approval to final manufacturing. These growing benefits are driving increased demand for automotive 3D printing for customized and personalized parts.

Based on offering, the automotive 3D printing market is segmented into hardware, software, services, and materials. In 2025, the hardware segment is estimated to account for the largest share of the automotive 3D printing market. The large share of this segment is attributed to advancements in 3D printers and related equipment that enable efficient and scalable production processes. In the automotive sector, the development of next-generation 3D printers has significantly improved precision, speed, and material compatibility. These advanced machines facilitate the production of highly complex, lightweight parts that enhance vehicle performance and minimize material waste. Additionally, the growth of 3D printing hardware is fueled by the availability of metal 3D printers capable of producing strong, heat-resistant components for automotive applications, such as engine parts, brake systems, and exhaust components. As these printers become more affordable and accessible, they are promoting wider adoption of 3D printing technology throughout the automotive industry.

Furthermore, the use of 3D printing hardware in the automotive industry has increased for prototyping, tooling, and mass production, creating new opportunities for customization, enhanced efficiency, and sustainable manufacturing practices. Several manufacturers are introducing 3D printing hardware to produce parts. For example, in October 2025, McLaren Automotive (U.K.) launched its new W1 hybrid hypercar, utilizing titanium 3D printing for the front uprights and wishbones of the advanced suspension system. These ongoing advancements in the hardware segment are expected to further drive the growth and adoption of 3D printing technology across the automotive market.

In 2025, North America is estimated to account for the largest share of the automotive 3D printing market. This large share is primarily driven by the presence of key market players and the increasing demand for customized 3D-printed products in the region. Additionally, the growing adoption of Industry 4.0 principles and expanding collaborations and investments by enterprises in the development of advanced 3D printing technologies and materials further contribute to this trend.

However, Asia-Pacific is slated to register the highest CAGR during the forecast period. The growth of this market is driven by several factors, including the emergence of automotive manufacturing hubs in countries such as China, Japan, South Korea, and India. Additionally, the low cost of raw materials for automotive 3D printing and the increasing adoption of 3D printing technologies to enhance vehicle design, reduce production costs, and comply with stringent environmental regulations are significant contributors to market growth.

The report includes a competitive landscape based on an extensive assessment of the key strategic developments that led market participants to adopt over the past three years. The key players profiled in the global automotive 3D printing market report 3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland).

|

Particulars |

Details |

|

Number of Pages |

300 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

22% |

|

Market Size (Value) |

USD 17.9 Billion by 2032 |

|

Segments Covered |

By Offering

By Technology

By Component

By Vehicle Type

By Application

|

|

Countries Covered |

North America (U.S. and Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Sweden, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Malaysia, Australia & New Zealand, Indonesia, Vietnam, and Rest of Asia-Pacific), Latin America (Mexico, Brazil, and Rest of Latin America), and Middle East & Africa (UAE, Saudi Arabia, Israel, and Rest of Middle East & Africa) |

|

Key Companies |

3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland) |

The global automotive 3D printing market size was valued at $3.7 billion in 2024.

The market is projected to grow from $4.5 billion in 2025 to $17.9 billion by 2032.

The automotive 3D printing market analysis indicates significant growth, reaching $17.9 billion by 2032 at a CAGR of 22% from 2025 to 2032.

The key companies operating in this market include 3D Systems Corporation (U.S.), Stratasys Ltd (U.S.), Desktop Metal, Inc. (ETEC) (U.S.), Dassault Systèmes S.E. (France), EOS GmbH (Germany), ExOne Operating, LLC (U.S.), Autodesk, Inc. (U.S.), Hoganas AB (Sweden), Proto Labs, Inc. (U.S.), Formlabs Inc. (U.S.), voxeljet AG (Germany), Markforged Holding Corporation (U.S.), MATERIALISE NV (Belgium), Ultimaker B.V. (Netherland), IC3D, Inc. (U.S.), Moog Inc. (U.S.), and Zortrax S.A. (Poland).

A prominent market trend in automotive 3D printing is the rising integration of artificial intelligence (AI) in design and production processes and growth in the use of sustainable and recyclable materials in 3D printing processes.

By region, North America holds the largest automotive 3D printing Market Share in 2025. However, the Asia-Pacific region is expected to witness the fastest growth, driven by growing automotive manufacturing hubs in countries such as China, Japan, South Korea, and India, the low cost of raw materials for automotive 3D printing, and the increasing adoption of 3D printing to enhance vehicle design, reduce production costs, and meet stringent environmental regulations.

The primary drivers of Automotive 3D printing market growth include the growing use of the fused deposition modeling (FDM) technique to produce automotive parts, the increasing use of 3D printing for tooling and manufacturing aids, and the rising demand for polymers in automotive 3D printing applications.

Published Date: May-2023

Published Date: Jul-2022

Published Date: May-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates