Resources

About Us

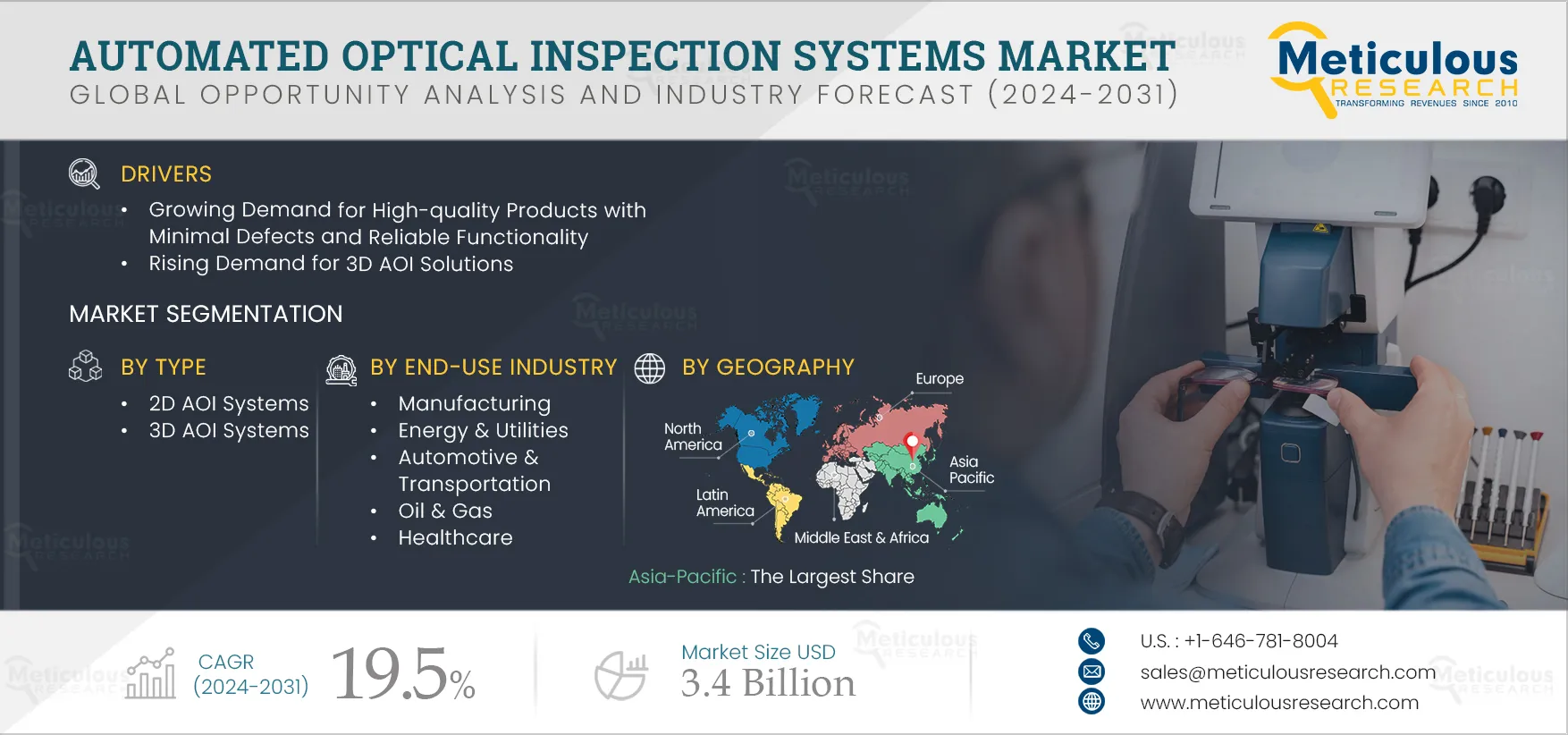

Automated Optical Inspection Systems Market Size, Share, Forecast, & Trends Analysis by Offering (Software, Hardware), Type (2D AOI, 3D AOI) Deployment (In-line AOI, Off-line AOI), End-use Industry (Electronics & Semiconductors, Healthcare), and Geography - Global Forecast to 2032

Report ID: MRSE - 1041269 Pages: 230 Sep-2024 Formats*: PDF Category: Semiconductor and Electronics Delivery: 24 to 72 Hours Download Free Sample ReportThe Automated Optical Inspection Systems Market is projected to reach $3.4 Billion by 2032, at a CAGR of 19.5% from 2025–2032. The growth of the automated optical inspection systems market is driven by the growing demand for high-quality products with minimal defects and reliable functionality and the rising demand for 3D AOI solutions. Furthermore, the growing demand for AOI systems for inspection of IC substrates is expected to generate growth opportunities for the players operating in this market.

The demand for high-quality products with minimal defects and reliable functionality is an important factor for the manufacturing industry. Several manufacturing companies are increasingly adopting the techniques and ensuring product quality to improve trust with customers by providing high-quality products. AOI systems use advanced imaging technology such as cameras, lasers, and other sensors that help to inspect products and components with high precision and speed.

Additionally, AOI systems help inspect products in real time during the manufacturing process. The increasing use of AOI systems allows defects to be identified immediately as they occur, enabling corrective action to be taken before defective products are further processed or shipped. With the increasing demand for AOI systems, several companies are launching solutions for the manufacturing industries to provide high-quality products with minimal defects. For instance, in April 2024, MEK Marantz Electronics Ltd (Japan) launched the Mek iSpector inline Automatic Optical Inspection system. This entry-level system is specifically designed to cater to customers with low-volume and high-mix production. The system is equipped with Mek Colour Histogram analysis, which provides accurate and reliable inspection results with low false calls. Such developments help increase the demand for the AOI systems during the forecast period.

Click here to: Get Free Sample Pages of this Report

The demand for 3D Automated Optical Inspection (AOI) solutions is steadily increasing across various industries to improve defect detection and enhance product efficiency. 3D AOI systems capture detailed height, shape, and volume information of products that provide more accurate inspection results compared to 2D AOI systems. Additionally, 3D AOI systems provide in-depth information that enables better detection of defects that are difficult to identify. Thus, the rising demand for 3D AOI solutions is driven by their ability to address the challenges posed by increasingly complex products and to improve inspection accuracy and efficiency.

Moreover, several manufacturers are increasingly focused on delivering high-quality products to meet stringent customer expectations and regulatory requirements. Thus, 3D AOI solutions contribute significantly to ensuring consistent product quality by providing thorough and reliable inspection capabilities. Hence, with increasing demand for 3D AOI systems, several companies are launching 3D AOI for high-resolution inspection of high-density PCBs and ultra-small components. For instance, in May 2022, Saki Corporation (Japan) launched a new 3Di series of next-generation in-line 3D automated optical inspection (3D AOI) systems for complex inspection of high-density printed circuit boards and boards with a combination of very small and tall components. Such increasing developments help to increase the demand for 3D AOI systems.

The growing integration of AI & ML technologies for defect detection in AOI systems is rapidly transforming the manufacturing industry. AI and ML algorithms help to analyze vast amounts of image data captured by AOI systems with higher accuracy and reliability compared to traditional rule-based approaches. Additionally, AI-powered AOI systems can perform defect detection in real time, enabling immediate feedback and corrective actions during the manufacturing process. With the increasing adoption of Industry 4.0, companies are increasingly integrating AI-powered AOI systems into manufacturing facilities for better production quality and performance.

Moreover, the manufacturing process is more complex with smaller components and complicated designs, AI and ML algorithms can handle the increased complexity of defect detection tasks. AI and ML help to analyze 3D images, multilayer PCB, and non-uniform surfaces more effectively compared to traditional methods. With the increasing adoption of AI-powered AOI systems, several companies are launching solutions to enhance productivity. For instance, in June 2024, Aetina Corporation (Taiwan) launched an AI solution specifically designed to enhance productivity in existing automated optical inspection (AOI) systems in manufacturing. The solution involves NVIDIA Metropolis for Factories and Aetina’s SuperEdge AI platforms, enabling users to reduce the workload of reinspecting the false rejects.

Based on offering, the automated optical inspection systems market is segmented into software, hardware, and services. In 2025, the hardware segment is expected to account for the largest share of above 60.0% of the automated optical inspection systems market. The segment's large market share is attributed to the AOI hardware providing a high level of accuracy and consistency in defect detection and the increasing adoption of AOI hardware to inspect PCBs at a faster rate than manual inspection. The AOI hardware systems allow for timely corrective actions, minimizing waste and rework, and generating detailed reports and documentation of images and data logs that are used for traceability purposes.

However, the services segment is expected to register the highest CAGR during the forecast period. This segment's growth is attributed to the increasing adoption of AOI services for designed and manufactured AOI systems according to specific industry needs, the rising need for AOI services to detect minor defects with high accuracy, ensuring consistent quality control, and the AOI services' help to ensure compliance with industry standards and regulations by providing detailed inspection records and documentation.

Based on type, the automated optical inspection systems market is segmented into 2D AOI systems and 3D AOI systems. In 2025, the 2D AOI systems segment is expected to account for the larger share of above 55.0% of the automated optical inspection systems market. The segment's large market share is attributed to the increasing adoption of 2D AOI machines for high-resolution cameras and advanced image processing algorithms to detect tiny defects and having user-friendly software interfaces that make it easy to set up and configure inspection parameters. 2D AOI systems help to classify defects based on severity or type, allowing manufacturers to prioritize and address critical issues promptly, provide real-time feedback to operators, and help to trigger automatic actions such as rejecting faulty PCBs.

However, the 3D AOI systems segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the increasing adoption of 3D AOI systems to reduce false call rates, measure volumetric inspection data, and measure height variations, which allows them to detect defects such as lifted leads, tombstoning, and other dimensional discrepancies. The growing adoption of 3D AOI systems for inspecting a wide range of products, such as intricate designs, complex geometries, and varying surface textures, and the 3D AOI systems provide real-time feedback during the production process to minimize defects and optimize manufacturing quality.

Based on deployment, the automated optical inspection systems market is segmented into in-line AOI and off-line AOI. In 2025, the in-line AOI segment is expected to account for the larger share of above 63.0% of the automated optical inspection systems market. The segment's large market share is attributed to the increasing use of in-line AOI for real-time detection to reduce the chances of producing a large batch of defective products before noticing an issue; the in-line AOI eliminates human subjectivity, ensuring that the inspection process is consistent and unbiased. The growing need for in-line AOI to detect defects early in the manufacturing process helps minimize rework and scrap, reducing overall production costs.

Also, this segment is expected to register a higher CAGR during the forecast period.

Based on end-use industry, the automated optical inspection systems market is segmented into electronics & semiconductors, aerospace & defense, healthcare, pharmaceutical, consumer goods, food & beverage, IT & telecommunications, automotive, energy & power, and other end-use industries. In 2025, the electronics & semiconductors segment is expected to account for the largest share of above 18.0% of the automated optical inspection systems market. The segment's large market share is attributed to the AOI systems helping to inspect electronic components and semiconductor devices quickly and efficiently for high-volume production environments; the increasing adoption of AOI systems to detect defects such as soldering defects, misplaced components, and pin misalignment in electronic components and semiconductor devices. AOI systems help to meet quality standards in the manufacturing process of electronics products and generate detailed inspection reports and statistical data to identify trends and optimize quality control measures.

However, the healthcare segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the increasing adoption of AOI to detect defects such as cracks, scratches, contamination, and dimensional inaccuracies in healthcare products and AOI systems providing documented inspection results and traceability in complying with the regulatory standards as healthcare products are subject to strict regulatory requirements. AOI systems provide consistent inspection results, reducing variability compared to manual inspection methods, and help deliver safe, reliable, and high-quality healthcare products to patients.

In 2025, Asia-Pacific is expected to account for the largest share of above 45.0% of the automated optical inspection systems market. Asia-Pacific’s significant market share can be attributed to the rise in demand for precise and defect-free manufactured products in the region, the increasing development of advanced cameras and software for 3D image inspection with AI-based automated systems, the growing miniaturization of printed circuit boards and electronic components in the manufacturing industry in Asia-Pacific; and the growing presence of electronics and semiconductor manufacturing plants in the region.

Also, this market is expected to register the highest CAGR of above 21.0% during the forecast period.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the automated optical inspection systems market are Nordson Corporation (U.S.), OMRON Corporation (Japan), DAIICHI JITSUGYO ASIA PTE. LTD. (A Subsidiary of DAIICHI JITSUGYO CO., LTD.) (Singapore), GÖPEL electronic GmbH (Germany), Koh Young Technology Inc. (South Korea), Pemtron Co., Ltd. (South Korea), Camtek Ltd. (Israel), Mycronic AB (Sweden), KLA Corporation (U.S.), Machine Vision Products, Inc. (U.S.), Saki Corporation (Japan), Test Research, Inc. (Taiwan), Viscom SE (Germany), Mirtec Co., LTD (South Korea), and Mek Europe BV (Netherlands).

In April 2025, Tupl, Inc. (U.S.) partnered with Aetina Corporation (Taiwan) to accelerate the adoption of AI vision solutions at the edge in factories worldwide. This collaboration offers a user-friendly, readily configurable, and scalable solution for Automated Optical Inspection (AOI) performed at the edge, enhancing operational efficiency and productivity for any customer.

In August 2024, ViTrox Corporation Berhad (Malaysia) launched the V510i Advanced 3D Optical Inspection (AOI) Solution series, a cutting-edge lineup that incorporates technologies designed to enhance quality control procedures in manufacturing workflow.

In July 2024, Test Research, Inc. (Taiwan) launched the Ultra-High-Speed 3D AOI TR7700QH SII, with 15 µm high resolution, 21 MP imaging, and large FOV inspection. The 3D AOI incorporates advanced AI algorithms and TRI's Smart Programming for inspection coverage and precision.

|

Particulars |

Details |

|

Number of Pages |

230 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

19.5% |

|

Market Size (Value) |

USD 3.4 Billion by 2032 |

|

Segments Covered |

By Offering

By Type

By Deployment

By End-use Industry

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Netherlands, Spain, Sweden, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (Saudi Arabia, UAE, Israel, and Rest of the Middle East & Africa) |

|

Key Companies |

Nordson Corporation (U.S.), OMRON Corporation (Japan), DAIICHI JITSUGYO ASIA PTE. LTD. (A Subsidiary of DAIICHI JITSUGYO CO., LTD.) (Singapore), GÖPEL electronic GmbH (Germany), Koh Young Technology Inc. (South Korea), Pemtron Co., Ltd. (South Korea), Camtek Ltd. (Israel), Mycronic AB (Sweden), KLA Corporation (U.S.), Machine Vision Products, Inc. (U.S.), Saki Corporation (Japan), Test Research, Inc. (Taiwan), Viscom SE (Germany), Mirtec Co., LTD (South Korea), and Mek Europe BV (Netherlands). |

The automated optical inspection systems market study focuses on market assessment and opportunity analysis through the sales of automated optical inspection systems across different regions and market segmentations. This study is also focused on competitive analysis for automated optical inspection systems based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies.

The automated optical inspection systems market is projected to reach $3.4 billion by 2032, at a CAGR of 19.5% from 2025 to 2032.

In 2025, the 2D AOI systems segment is expected to account for the larger share of above 55.0% of the automated optical inspection systems market. The segment's large market share is attributed to the increasing adoption of 2D AOI machines for high-resolution cameras and advanced image processing algorithms to detect tiny defects and the machines having user-friendly software interfaces that make it easy to set up and configure inspection parameters. 2D AOI systems help to classify defects based on severity or type, allowing manufacturers to prioritize and address critical issues promptly, providing real-time feedback to operators, and helping to trigger automatic actions such as rejecting faulty PCBs.

The healthcare segment is expected to register the highest CAGR during the forecast period. The growth of this segment is attributed to the increasing adoption of AOI to detect defects such as cracks, scratches, contamination, and dimensional inaccuracies in healthcare products and AOI systems providing documented inspection results and traceability in complying with regulatory standards as healthcare products are subject to strict regulatory requirements. AOI systems provide consistent inspection results, reducing variability compared to manual inspection methods, and help deliver safe, reliable, and high-quality healthcare products to patients.

The growth of the automated optical inspection systems market is driven by the growing demand for high-quality products with minimal defects and reliable functionality and the rising demand for 3D AOI solutions. Furthermore, the growing demand for AOI systems for inspection of IC substrates is expected to generate growth opportunities for the players operating in this market.

The key players operating in the automated optical inspection systems market are Nordson Corporation (U.S.), OMRON Corporation (Japan), DAIICHI JITSUGYO ASIA PTE. LTD. (A Subsidiary of DAIICHI JITSUGYO CO., LTD.) (Singapore), GÖPEL electronic GmbH (Germany), Koh Young Technology Inc. (South Korea), Pemtron Co., Ltd. (South Korea), Camtek Ltd. (Israel), Mycronic AB (Sweden), KLA Corporation (U.S.), Machine Vision Products, Inc. (U.S.), Saki Corporation (Japan), Test Research, Inc. (Taiwan), Viscom SE (Germany), Mirtec Co., LTD (South Korea), and Mek Europe BV (Netherlands).

Asia-Pacific is expected to register the highest CAGR of above 21.0% during the forecast period. The growth of this region is attributed to the rise in demand for precise and defect-free manufactured products in the region, the increasing development of advanced cameras and software for 3D image inspection with AI-based automated systems, the growing miniaturization of printed circuit boards and electronic components in the manufacturing industry in Asia-Pacific; and the growing presence of electronics and semiconductor manufacturing plants in the region.

Published Date: Feb-2025

Published Date: Nov-2024

Published Date: Nov-2024

Published Date: May-2024

Published Date: Feb-2023

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates