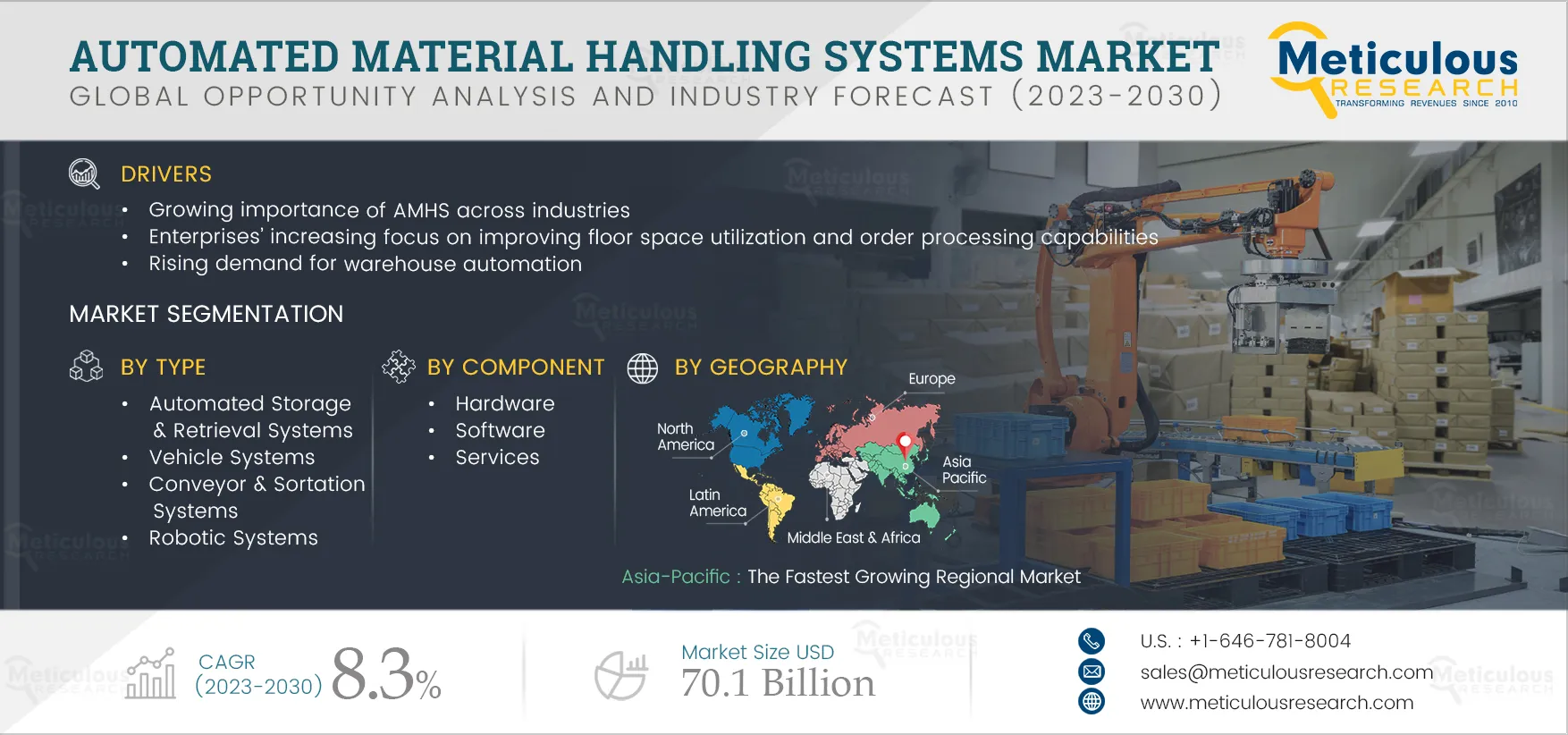

The Automated Material Handling Systems Market is projected to reach $70.1 billion by 2030, at a CAGR of 8.3% during the forecast period 2023–2030. The growth of this market is driven by the growing importance of AMHS across the industry, enterprises’ increasing focus on improving floor space utilization and order processing capabilities, and rising demand for warehouse automation. However, the high initial costs involved in deploying AMHS are expected to restrain this market’s growth. The growing significance of online retail platforms and associated ted supply chains, increasing utilization of RFID and barcode technologies, integration of cloud and IoT technologies in AMHS, and the advent of Industry 4.0 are expected to provide significant growth opportunities for stakeholders in this market. However, expansion and automation of warehouses without hampering operations and cybersecurity risk a major challenge to the growth of this market.

Here are the top 10 companies operating in the Automated Material Handling Systems Market

Established in 1937 and headquartered in Osaka, Japan, Daifuku Co., Ltd. is a leading provider of material handling systems. The company develops, manufactures, and provides various automation & logistic solutions to the automotive, airport, manufacturing, public, and other sectors. The company also offers aftermarket services, such as maintenance, regular inspections, and retrofits. Daifuku continuously develops and introduces innovative products, such as manufacturing & distribution systems, semiconductor product line systems, flat panel display production line systems, automobile production line systems, and airport technologies. Furthermore, it offers material handling solutions that meet automation and labor-saving needs for the manufacturing sector.

The company operates through eleven reportable segments: Electronics; Commerce, retail; Automobiles, Autoparts; Airport; Transportation, Warehousing; Chemicals, Pharmaceuticals; Food; Machinery; Precision Equipment, Printing, Office Equipment; Iron, Steel, Nonferrous Metals; and Other.

Some of its subsidiaries are Daifuku Plusmore Co., Ltd. (Japan), Contec Co., Ltd. (Japan), Daifuku Business Service Corporation (Japan), and Scarabee Aviation Group – Japan Co., Ltd. (Japan). With its subsidiaries and a strong distribution network, the company has a geographical presence across Asia, North America, Europe, and other regions. As of March 2022, the company had a headcount of 12,436 employees worldwide.

Dematic Corp. (A Part of KION GROUP AG)

Founded in 1819 and headquartered in Georgia, U.S., Dematic is a leading provider of material handling systems. Dematic Corp. is a subsidiary of KION GROUP AG (Germany). Dematic is a global engineering company that designs and builds logistics solutions that optimize material & information flow from receiving to shipping in factories, warehouses, or distribution centers. The company’s products and software can be configured to meet the supply chain needs of companies large and small across various industries, from manufacturing and e-commerce to wholesale and healthcare. Dematic offers training and consultancy to support its systems, modernization and upgrades, and field service operations. The company has installed over 6,000 material handling systems around the world. KION GROUP AG operates through three reportable segments: Industrial Trucks & Services, Supply Chain Solutions, and Corporate Services.

Some of its subsidiaries are Linde Material Handling GmbH (Germany), KION India Private Limited (India), KION Financial Services GmbH (Germany), Kion Rental Services SpA (Italy), Dematic Limited (U.K.), among others. With its subsidiaries and a strong distribution network, the company has a presence across EMEA, the Americas, and Asia-Pacific. As of December 2022, the company had a headcount of 41,149 employees worldwide.

Honeywell International Inc.

Founded in 1906 and headquartered in Indiana, U.S., Honeywell International Inc. is a leading single-source provider of intelligent automated material handling solutions. The company designs, manufactures, integrates, and installs comprehensive material handling automation solutions, such as conveyors, sortations, palletizers & robotics, and automated storage and retrieval systems. Through an extensive portfolio of automation equipment, warehouse execution system software, services, and support, the company provides businesses with a competitive edge and optimizes operational performance that drives fulfillment productivity, mainly for retailers, manufacturers, and logistics providers across the globe. The company operates through four reportable segments: Aerospace, Honeywell Building Technologies, Performance Materials and Technologies, and Safety and Productivity Solutions.

Some of its subsidiaries are UOP LLC (U.S.), Maxon Corporation (U.S.), RAE Systems, Inc. (U.S.), Honeywell Aerospace (U.S.), Novar GmbH (Germany), and Sparta Systems, Inc. (U.S.). With its subsidiaries and strong distribution network, the company is present across the U.S., Europe, and other countries. As of December 2022, the company had a headcount of 97,000 employees worldwide.

Toyota Industries Corporation

Established in 1926 and headquartered in Aichi, Japan, Toyota Industries Corporation is a leading manufacturer of lift trucks. The company manufactures textile machinery, car air-conditioning compressors, automobiles, engines, car electronics, and materials handling equipment. The company develops, sells, and provides services for a wide portfolio of material-handling equipment products, ranging from lift trucks to material-handling systems. The company’s material handling equipment business is operated under a two-organization structure: Toyota Material Handling Group (TMHG) and Toyota Advanced Logistics Group (TALG). The company operates through three reportable segments: Materials Handling Equipment, Automobile, and Textile Machinery.

Some of its subsidiaries are Bastian Solutions LLC (U.S.), Vanderlande Industries Holding B.V. (Netherlands), Toyota L&F (Japan), Toyota Material Handling (U.S.), Toyota Material Handling Europe (France), Raymond Corporation (U.S.), Aichi Corporation (Japan), and Advanced Logistics Solutions Co., Ltd. (Japan). As of March 2022, the company had a headcount of 70,000 employees worldwide.

SSI SCHÄFER AG

Founded in 1937 and headquartered in Neunkirch, Germany, SSI SCHÄFER AG is a private company and a leading material handling products and solutions provider. The company provides cutting-edge modular warehousing and logistics solutions. The company’s wide-ranging portfolio comprises design, planning, consulting, and customer-specific aftersales services and maintenance. The company also provides a broad systems portfolio ranging from manual to highly automated storing, conveying, and picking systems, including a comprehensive software portfolio.

With its subsidiaries and a strong distribution network, the company has a geographical presence across North America, Latin America, Europe, Asia-Pacific, and the Middle East & Africa. The company upholds an excellent international position with five competence centers in Neunkirchen (DE), Giebelstadt (DE), Graz (AT), Friesach (AT), and Neunkirch (CH), as well as many production facilities together with over 70 operating companies across the globe.

Murata Machinery, Ltd.

Founded in 1935 and headquartered in Kyoto, Japan, Murata Machinery, Ltd. is a privately held Japanese international company that manufactures various machinery ranging from factory automation products to communication equipment. The company offers advanced logistics & automation systems mainly focused on automated storage and transportation systems and automated material handling systems for cleanrooms designed particularly for semiconductor fabs.

Some of its subsidiaries are AGVE AB (Sweden), Nippon Shooter Ltd. (Japan), Cimcorp Oy (Finland), and Silex Technology America, Inc. (U.S.). With its subsidiaries and a strong distribution network, the company has a geographical presence across Asia, North America, Latin America, and Europe.

KNAPP AG

Founded in 1952 and headquartered in Hart bei Graz, Austria, KNAPP AG is a global market leader for integrated intralogistics solutions and offers turnkey systems in warehouse automation and warehouse logistics. The company develops customized solutions such as robotics & handling, storage, picking, and conveying & sorting with the help of cutting-edge technology, particularly for warehouse logistics. The company’s offerings cater to various sectors, including Healthcare, Fashion, Retail, Food Retail, Industry, and Wholesale.

Some of its subsidiaries are KNAPP Systemintegration GmbH (Austria), KNAPP Deutschland GmbH (Germany), KNAPP Italia S.R.L. (Italy), KNAPP Deutschland GmbH (Germany), KNAPP Benelux B.V. (Netherlands), and KNAPP Polska Sp. z o.o. (Poland). With its subsidiaries and a strong distribution network, the company has a geographical presence across North America, Latin America, Europe, Asia, and the Middle East & Africa.

BEUMER Group GmbH & Co. KG

Founded in 1935 and headquartered in Deutschland, Germany, BEUMER Group GmbH & Co. KG is a global leader in designing and manufacturing intralogistics systems, mainly for conveying, loading, palletizing, packaging, sortation, and distribution. The company’s offerings cater to various industries, including aviation, building materials, cement/AFR, chemicals, logistics, E-commerce, minerals & mining, energy, fashion, consumer goods, retail, fertilizer, and metallurgy.

Some of its subsidiaries are Enexco Teknologies India Limited (India), Beumer Group Technology Iberia S.L. (Spain), Beumer Group Czech Republic A.S. (Czech Republic), Beumer Group UK Limited (U.K.), and Codept GmbH (Germany). With its subsidiaries and a strong distribution network, the company has a geographical presence across North America, South America, Asia, Australia, Europe, and the Middle East and representatives in more than 70 countries.

Swisslog Holding AG (A Part of KUKA AG)

Founded in 1900 and headquartered in Buchs, Switzerland, Swisslog Holding AG is a leading global supplier of intelligent automation solutions. Swisslog Holding AG is a subsidiary of KUKA Aktiengesellschaft (KUKA AG) (Germany). The company has a broad product portfolio of key technologies, such as conveyor systems, ASRS, AGVs, shuttle systems, monorails, robotics, and warehouse management software. The company also provides innovative solutions & services, including consulting, project implementation, customer service, best-in-class technologies, and software.

Swisslog offers a wide range of traditional and advanced technologies for automated storage and retrieval of pallets and smaller goods, such as cartons or bins. These fully automated systems boost warehouse quality, flexibility, and efficiency. The company’s offerings cater to different industries, including food & beverage, pharmaceuticals, retail, and E-commerce.

KUKA AG operates through five reportable segments: Systems, Robotics, Swisslog, Swisslog Healthcare, and China. Some of its subsidiaries are Reis Robotics (Germany), KUKA Roboter CEE GmbH (Germany), Thompson Friction Welding (U.K.), KUKA Robotics China Co., Ltd. (China), and Reis Group Holding Gmbh & Co. Kg (Germany). With its subsidiaries and a strong distribution network, the company has a geographical presence across EMEA, the Americas, and Asia-Pacific. As of December 2022, the company had a headcount of 15,064 employees worldwide.

TGW Logistics Group GmbH

Founded in 1969 and headquartered in Marchtrenk, Austria, TGW Logistics Group GmbH is a privately held company and a leading systems provider of highly automated, flexible solutions that support distribution and fulfillment for leading retailers and global brands in e-commerce, apparel, general merchandise, and grocery. The company offers advanced solutions ranging from small material handling applications to complex centers. The company’s offerings cater to prominent retailers and global brands in the e-commerce, apparel, general merchandise, and grocery sectors.

Some of its subsidiaries are TGW Robotics GmbH (Europe), TGW Mechanics GmbH (Europe), TGW Systems Integration GmbH (Europe), and TGW Systems Inc. (U.S.). With its subsidiaries and a strong distribution network, the company has a geographical presence across the U.K., North America, Benelux, China, France, Germany, Italy, Lithuania, Poland, Scandinavia, Switzerland, Spain, and South Korea. As of December 2022, the company had a headcount of 4,400 employees worldwide.