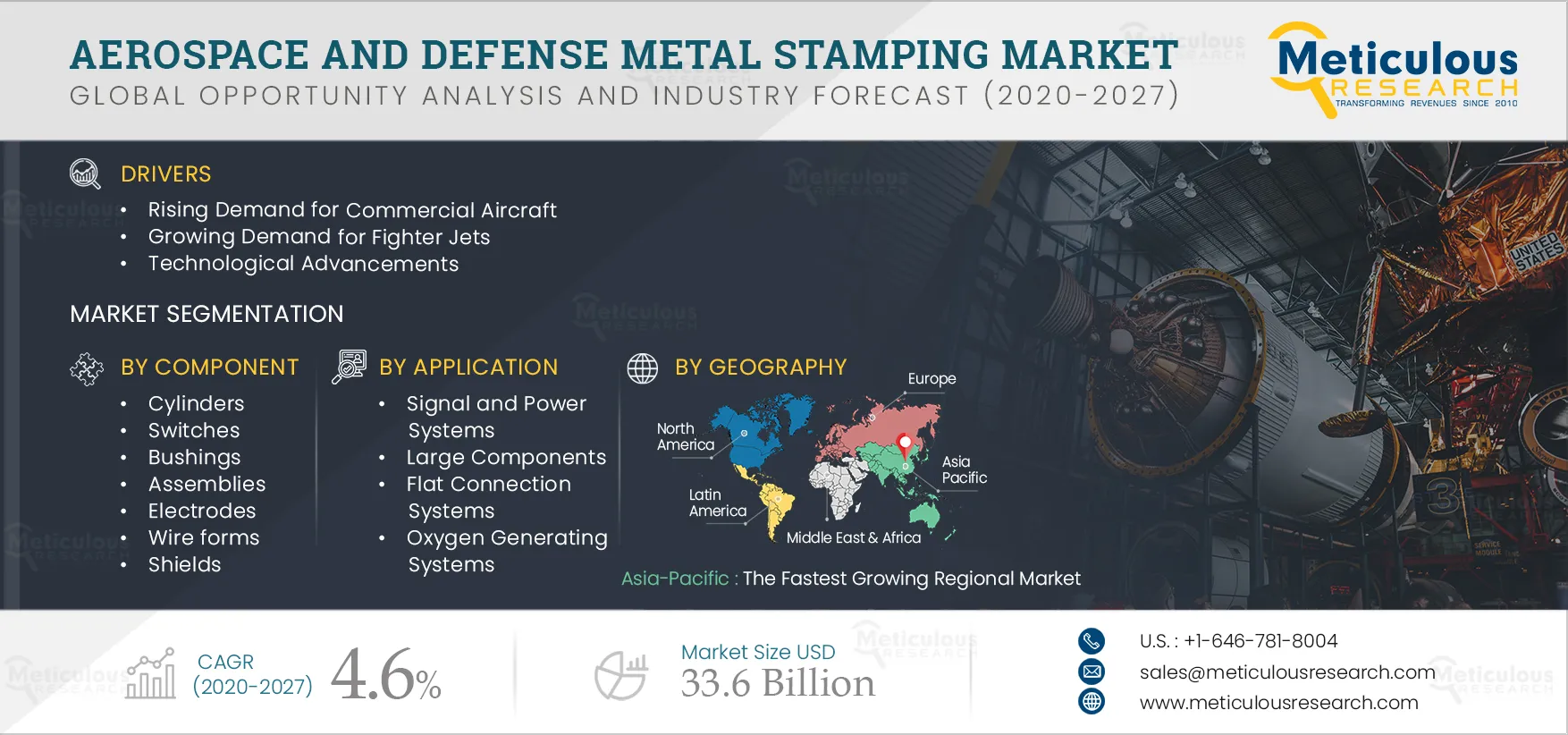

The Aerospace and Defense Metal Stamping Market is expected to reach $33.6 billion by 2027, at a CAGR of 4.6% during the forecast period of 2020 to 2027. Metal stamped components are the essential parts for the aerospace and defence industry. Aerospace vehicles require metal stamped components of all sizes ranging from airframes to nuts & bolts. Increasing number of passengers traveling by air, growing demand for commercial aircraft, and huge defense budgets in the country are expected to drive the demand for metal-stamped components in the country. The surge of aerospace and defence metal stamping market is majorly driven by the rising demand for commercial aircraft, growing demand for fighter jets with growing security concerns across the globe, increasing demand for high-quality precision components, rising investments in metal stamping facilities, and rising technological advancements. Moreover, the total aerospace exports from the U.S. reached $136 billion in 2019. Such a growing demand for commercial aircraft and rising exports of aerospace products from the country are, in turn, expected to boost the demand for stamped metal parts and components.

Here are the top 10 companies operating in the Aerospace and Defence Metal Stamping Market

American Industrial Company (U.S.)

American Industrial Company is involved in precision metal stampings and assemblies. The company’s metal stamping services include progressive die stamping, coining or shallow draw stamping, blanking, piercing, laser cutting, bending, and forming. The company uses stainless, cold/hot rolled, and galvanized steels, as well as aluminum, brass, copper, and high strength low alloy steel (HSLA) for stamping. The company offers its products for the automotive, construction, medical, power tools, and solar-green building & sporting goods industries. It also offers custom metal stampings products for the aerospace and military/defense industry.

The company primarily operates in the North America.

Kölle GmbH (Germany)

Kölle operates as a metal working company. The company manufactures stamping tools with part and conveyor feed systems for the automotive, aerospace, and electrical engineering industries. The company offers various products and services, including punching-bending-assembling; carrier frame for flat seals; metal parts for thermal and acoustic insulations; hollow rotors/rotor spiral; and structured fine sheets. The company manufactures a wide variety of stamping, drawing, and bending parts with aluminum, steel, and stainless steel. The company has its primary presence across Europe.

FORGEAVIA (France)

The company is mainly involved in the field of stamping, die forging, and free forging mainly for aeronautics and defense. It offers forged parts from a few grams to up to 50kg in many types of materials, like steel, stainless, aluminum, titanium, Inconel, copper, and bronze, among others. The company mainly offers its products in the aeronautics, railways, defense, and even extreme sports markets. FORGEAVIA offers custom solutions in the aerospace and defense industry.

The FORGEAVIA operates under the MECAPOLE brand. The company has its primary presence in France.

Weiss-Aug Co., Inc. (U.S.)

Weiss-Aug is mainly involved in the manufacturing of insert injection molding, precision metal stamping, in-die assembly stamping, and automated assembly. Adding to this, its capabilities include research and development, prototyping, fabrication, progressive die tooling, crimping, coating, laser welding, program management, designing, and engineering. Also, the company`s secondary operations include heat treating, finishing, degreasing, and packaging. Weiss-Aug offers its products for medical, automotive, interconnect, and aerospace & defense. The company offers its components and sub-assemblies for specialty aerospace connectors, sensors, MEMS, and semiconductor applications in various metals, like copper alloys, stainless and carbon steels, nickel alloys, titanium, pre/post-plated and cladded materials, and skived materials.

The company has its geographic presence in North America and Latin America.

National Die Company, Inc. (U.S.)

National Die Company is engaged in manufacturing deep drawn stampings and parts. The materials used in the manufacturing of deep drawn stampings and parts include stainless steel, aluminum, copper, brass, bronze, and low-carbon cold-rolled steels, among others. The company serves the aerospace, defense/military, medical, automotive, appliances, communication, electronics, battery, electric, engine components, thermal, and miscellaneous industries.

National Die Company has its geographic presence in North America.

Hudson Technologies (U.S.)

Hudson Technologies is a manufacturer of deep drawn metal enclosures, cases, and stampings, including metal diaphragms. The company’s product portfolio includes battery enclosures, flat & corrugated precision metal diaphragms, seamless enclosures, and others. The company offers metal stamping products and services to a wide range of industries, such as aerospace & defense, energy storage, medical products, oil & gas, and semiconductor. Hudson’s metal stamped parts are widely used in military aircraft housings and enclosures; instrumentation; oxygen generating systems; and relay, switch, and lighting systems. In the aerospace and defense industry, the company works with a variety of metals, including steel, stainless steel, titanium, aluminum, cold-rolled steel, brass, copper, HY-MU 80 and other shielding alloys, nickel, and cupro nickel.

The company has geographic presence across North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. As of 2017, the company had a headcount of nearly 250 employees worldwide.

Keats Manufacturing Company (U.S.)

The company is mainly involved in the manufacturing of metal stampings, wire forms, and assemblies. The company provides custom small metal stampings, wire forms, brackets, clips, shields, bushings, and assembly products. The company’s Precision Metal Stamping segment offers a variety of components, such as electronic terminals, sensor components, yokes, thrust washers, heat sinks, printer cartridge blades, medical components, inserts, fuse clips, brackets, contacts, covers, latches, and furniture parts. Keats Manufacturing offers its products to various industries, such as aerospace, appliances, automotive, electrical distribution, communications, construction, renewable energy, general manufacturing, medical/medical devices, and military/defense. The company provides custom metal stamping products for the aerospace and military/defense industry.

The company has its primary presence in the North American region.

K S Tooling, Inc. (U.S.)

K S Tooling is a manufacturer of high-speed thin metal stampings. The company’s product portfolio includes shields, spring clips, lead frames, pin grid arrays, backplane connectors, assemblies, tools, and dies. The company offers stamped products for the medical, automotive, interconnect, fiber optic, aerospace, defense, dental, consumer products, and housing and construction industries. K S Tooling also offers custom metal stamping products for the aerospace and military/defense industry. The company has its primary presence in the U.S.

D&H Industries, Inc. (U.S.)

D&H Industries is mainly involved in metal stamping and fabrication. The company offers progressive stamping, deep drawn stamping, metal forming, value-added assembly, robotic welded assemblies, including resistance welding, and MIG/TIG welding. D&H Industries offers its products to various industries, such as agriculture, alternative energy, ATV and marine, automotive, defense, engine components, furniture, heavy equipment, lawn and garden, material handling, power transmission, railroad, and wing energy.

The company primarily operates in the North America region.

Pacific Metal Stampings, Inc. (U.S.)

Pacific Metal Stampings is engaged in the metal stamping services market. The company offers short-run metal stamping, custom metal stamping, metal forming, tool and die, and secondary services. Pacific Metal offers metal stamping products for several industries, namely, aerospace, medical, construction, automotive, electronic, military, green technologies, marine, and lighting. Pacific Metal also provides high-quality aerospace parts and fittings, including aerospace bolts, screws, studs, pins, nuts, and other specialty products. Metal forming, bending, and piercing are some of the services the company offers in the aerospace industry. Pacific Metal Stamping is also involved in the manufacturing of custom metal stampings for the aerospace and defense industry, such as anchor bolts, self-tapping screws, cotter pins, shims, and castle nuts. The company has its presence in the U.S.

Popular Mentions: Tempco Manufacturing Company, Inc., Klesk Metal Stamping, Co., ACRO Metal Stamping, Co., Harvey Vogel Manufacturing Co., Henan Kathysia Industrial Co, Ltd., and Wiegel Tool Works, Inc.