Resources

About Us

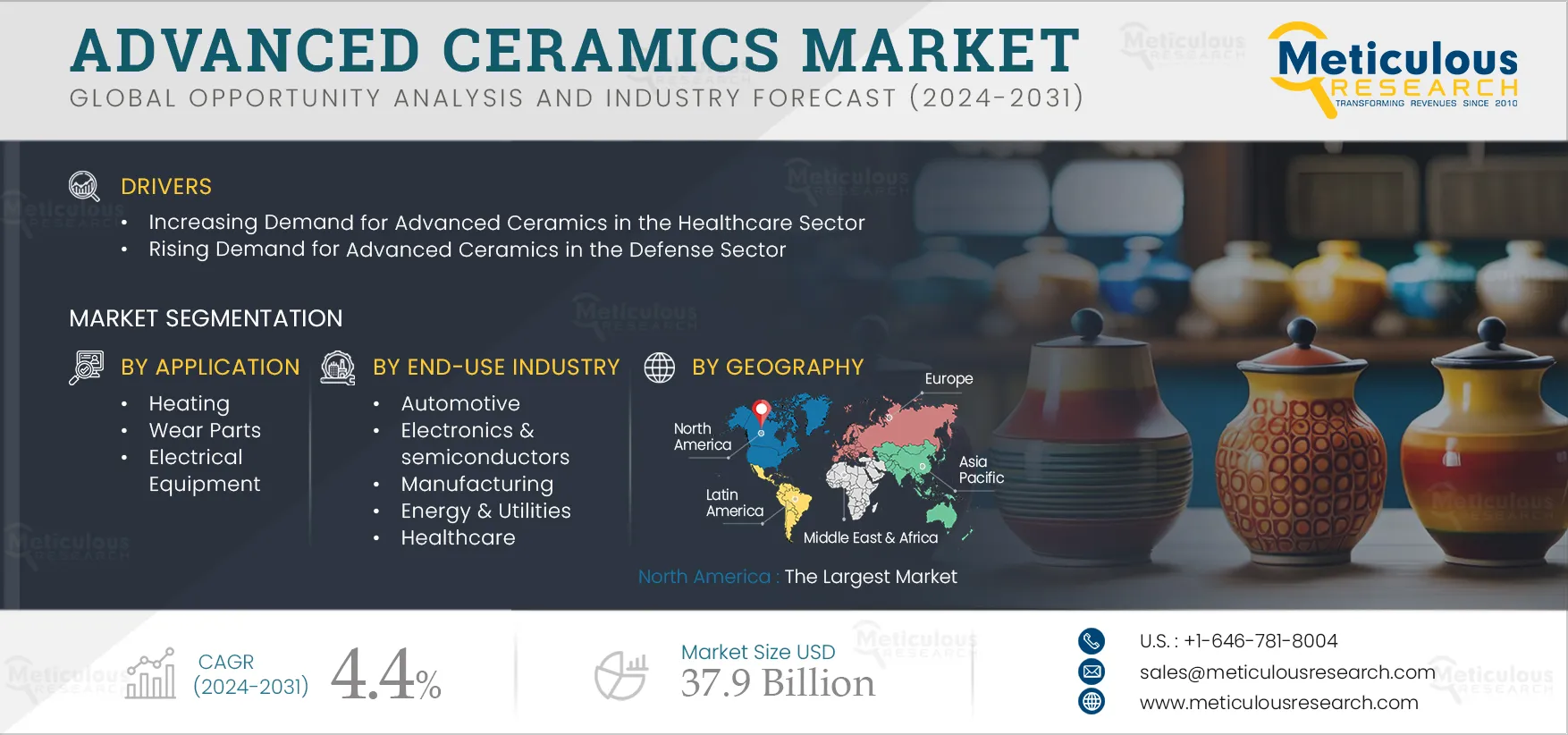

Advanced Ceramics Market Size, Share, Forecast, & Trends Analysis by Material (Alumina, Zirconia, Silicon Carbide), Product (Ceramic Coatings, Ceramic Matrix Composites), Application, End-use Industry (Electronics & Semiconductors, Manufacturing, Healthcare), and Geography - Global Forecast to 2032

Report ID: MRCHM - 1041190 Pages: 250 May-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe Advanced Ceramics Market is expected to reach $37.9 billion by 2032, at a CAGR of 4.4% from 2025 to 2032. The growth of this market is driven by the increasing adoption of advanced ceramics in the healthcare sector and the rising demand for advanced ceramics in the defense sector. Moreover, the increasing use of nanotechnology and the growing adoption of advanced ceramics in the automotive sector are expected to offer growth opportunities for the players operating in this market.

Advanced ceramics play a crucial role in various applications within the healthcare sector due to their unique properties and capabilities. Advanced ceramics materials zirconia and alumina are frequently used in dental restorations such as crowns, bridges, and implants. Their biocompatibility, durability, and natural appearance make them an ideal choice for dental applications. Also, advanced ceramics are utilized in orthopedic implants for joints, including hip and knee replacements. Their high strength, wear resistance, and biocompatibility make them suitable for long-term implantation. Furthermore, ceramics are also used in the fabrication of biomedical sensors for various applications, such as monitoring vital signs, detecting biomolecules, and measuring biological parameters.

Several leading global key players are taking initiatives to improve their business strategies. For instance, in January 2022, Lithoz GmbH (Austria) partnered with Himed (U.S.) to upgrade 3D-printable medical-grade bioceramics. The continued advancements in ceramic materials and manufacturing techniques, coupled with ongoing research in the healthcare field, are expected to lead to further innovations and expanded applications of ceramics in healthcare in the future.

Click here to: Get Free Sample Pages of this Report

Advanced ceramics are utilized in sensor technology for defense purposes, including infrared sensors, radar systems, and chemical sensors. Ceramic materials enable the development of high-performance sensors with enhanced sensitivity, reliability, and durability, contributing to surveillance, reconnaissance, and threat detection capabilities. Also, ceramics play a crucial role in stealth technology. Radical-absorbing materials and coatings are applied to military aircraft, ships, and vehicles to reduce their radar cross-section and enhance stealth capabilities. Ceramics with specific electromagnetic properties are engineered to absorb and dissipate radar waves, making military platforms less detectable by enemy radar systems.

Advanced ceramics contribute significantly to the defense sector by providing essential materials for armor protection, vehicle and aircraft components, electronic systems, sensor technology, stealth capabilities, missile systems, chemical and biological defense, and unmanned aerial vehicles. The ongoing development and innovation in ceramic materials continue to drive advancements in defense technology, ensuring the effectiveness and superiority of military capabilities.

The adoption of advanced ceramic components for e-mobility applications is experiencing significant growth. Advanced ceramics such as silicon carbide (SiC) and aluminum nitride (AlN) offer high thermal conductivity properties. This makes them ideal for use in electric vehicle (EV) power electronics, including inverters and power modules. By efficiently dissipating heat generated during power conversion processes, ceramic components help improve the performance and reliability of EV powertrain systems. Also, ceramic materials are capable of withstanding high voltages and temperatures, making them well-suited for use in EV batteries and charging systems. Ceramic components help to ensure the safe and efficient operation of battery management systems, DC-DC converters, and onboard chargers in electric vehicles.

The growing adoption of advanced ceramic components for e-mobility applications reflects the industry's commitment to innovation, efficiency, and sustainability in the transition to electric transportation. As electric vehicle technology continues to evolve and demand for EVs increases, the role of ceramics in enabling high-performance and reliable electric vehicle systems is expected to expand in the future.

Advanced ceramics play a vital role in enhancing automotive performance, efficiency, and sustainability by enabling innovative solutions in engine design, emissions control, braking systems, fuel injection, electrical systems, and lightweight. They contribute to the automotive industry by helping to reduce vehicle weight and improve fuel efficiency. Ceramic materials, such as aluminum oxide and silicon carbide, can be used to replace heavier metallic components in various vehicle systems, including engine parts, chassis components, and body structures.

Ceramic-based sensors are used in automotive exhaust systems for monitoring and controlling emissions. Oxygen sensors, particulate matter sensors, and NOx sensors often utilize ceramic materials due to their high-temperature resistance, chemical stability, and responsiveness to changes in exhaust gas composition. These sensors help ensure compliance with emissions regulations and optimize engine performance.

As automotive manufacturers continue to make advancements in vehicle technology and emissions reduction, the demand for advanced ceramics in the automotive sector is expected to grow.

In 2025, the alumina segment is expected to account for the largest share of 35.0% of the global advanced ceramics market. The segment’s large market share is attributed to the increasing focus on material-centric capabilities, rising R&D investments, increasing demand for alumina-based advanced ceramics in harsh applications, and increasing adoption of alumina-based advanced ceramics in electronics & semiconductors. In addition, the benefits offered by alumina, such as high hardness, chemical resistance, biocompatibility, electrical insulation, and excellent thermal stability, contribute to this segment's growth. Also, several leading key players are taking initiatives to improve productivity. For instance, in October 2024, Alteo (France) launched Alteo’s HYCal brand of alumina. This new brand is dedicated to advanced ceramics and strengthens Alteo’s commitment to excellence and quality to support customers’ growth.

However, the titanate segment is expected to register the highest CAGR during the forecast period of 2025–2032. The growing adoption of titanate-based materials in antennas and resonators, increasing investment in wireless communication, and increasing use of titanate-based ceramics materials in medical devices are expected to support the growth of this segment.

In 2025, the monolithic ceramics segment is expected to account for the largest share of 70.0% of the global advanced ceramics market. The segment’s large market share is attributed to the rising trend towards miniaturization and integration of components in electronics and microdevices, the growing demand for these materials in various applications where conventional materials fail, and the rising adoption of monolithic ceramics in automotive, aerospace, electronics, energy, medical, and chemical processing industries.

However, the ceramic matrix composites segment is expected to grow at the highest CAGR during the forecast period of 2025–2032. The rising adoption of ceramic matrix composites in aerospace, gas turbines, and other high-temperature environments and the rising need for ceramic matrix composites in harsh chemical environments are expected to support the growth of this segment. In addition, the benefits offered by ceramic matrix composites, such as high-temperature performance, corrosion and wear resistance, lightweight, high strength, and excellent thermal shock resistance, are expected to contribute to this segment's growth.

In 2025, the electronics & semiconductors segment is expected to account for the largest share of 55.0% of the global advanced ceramics market. The segment’s large market share is attributed to the rising adoption of advanced ceramics in electronic devices for insulating, superconducting, semiconducting, magnetic, and piezoelectric applications and the growing demand for materials that provide precise dimensions, high reliability, and excellent performance. The benefits of advanced ceramics in the semiconductor industry include superior thermal management, electrical insulation, chemical resistance, dimensional stability, purity, wear resistance, customization options, and longevity, all of which contribute to enhanced performance, reliability, and efficiency in semiconductor manufacturing processes.

However, the healthcare segment is expected to register the highest CAGR during the forecast period of 2025–2032. The rising adoption of advanced ceramics in implantable medical devices, diagnostic imaging equipment, therapeutic medical devices, and consumable medical devices, increasing use of ceramics coatings, and rising sales of high-performance ceramics are expected to support the growth of this segment.

In 2025, North America is expected to account for the largest share of 33.0% of the global advanced ceramics market. North America’s large market share is attributed to the presence of prominent players offering advanced ceramics materials. For instance, in June 2022, CoorsTek, Inc. (U.S.) announced its advanced materials processing (AMP) expansion in Benton, Arkansas. CoorsTek invested over USD 50 Million to create a state-of-the-art advanced materials manufacturing campus that will lead to additional innovation in numerous markets at the 230,000-square-foot facility. Furthermore, the increasing adoption of advanced ceramics in the automotive sector, the rising popularity of EVs, rising sales of high-performance ceramics, and rising demand for high-quality semiconductors that enable ultra-high frequency signal transmission are supporting the market growth.

However, the Asia-Pacific region is projected to register the highest CAGR of 6.0% during the forecast period. This region's rapid growth is mainly driven by the rising adoption of advanced ceramics in various end-use industries, ongoing R&D activities focused on enhancing ceramic properties and manufacturing processes, and market players’ efforts to launch advanced ceramics materials. For instance, in February 2021, CoorsTek, Inc. (U.S.) announced the expansion of its manufacturing footprint in Southeast Asia.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3–4 years. Some of the key players operating in the advanced ceramics market are KYOCERA Corporation (Japan), CeramTec GmbH (Germany), CoorsTek, Inc. (U.S.), Morgan Advanced Materials plc (U.K.), AGC Inc. (Japan), Elan Technology (U.S.), 3M Company (U.S.), MARUWA CO., LTD. (Japan), Ortech Inc. (U.S.), Saint Gobain Ceramic Material (U.S.), Advanced Ceramic Materials (U.S.), McDanel Advanced Material Technologies (U.S.), BCE Special Ceramics GmbH (Germany), STC Material Solutions (U.S.), and Technocera Industries (India).

In August 2024, Lucideon CICS Limited (U.K.) signed a MoU with the National Composites Centre (NCC) (U.K.) to develop advanced ceramic composites solutions to meet a growing market demand for materials.

In August 2021, XJet Ltd. (Israel) [AD6] announced the commercial availability of alumina, adding to its portfolio of additive manufacturing materials.

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

4.4% |

|

Market Size (Value) |

USD 37.9 Million by 2032 |

|

Segments Covered |

By Material

By Product

By Application

By End-use Industry

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Switzerland, Poland, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, Singapore, Australia & New Zealand, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Israel, and Rest of the Middle East & Africa) |

|

Key Companies |

KYOCERA Corporation (Japan), CeramTec GmbH (Germany), CoorsTek, Inc. (U.S.), Morgan Advanced Materials plc (U.K.), AGC Inc. (Japan), Elan Technology (U.S.), 3M Company (U.S.), MARUWA CO., LTD. (Japan), Ortech Inc. (U.S.), Saint Gobain Ceramic Material (U.S.), Advanced Ceramic Materials (U.S.), McDanel Advanced Material Technologies (U.S.), BCE Special Ceramics GmbH (Germany), STC Material Solutions (U.S.), and Technocera Industries (India). |

The advanced ceramics market study focuses on the market assessment and opportunity analysis through the sales of advanced ceramics across different regions and countries across different market segmentation; this study is also focused on competitive analysis for advanced ceramics based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies.

The advanced ceramics market is projected to reach $37.9 billion by 2032, at a CAGR of 4.4% during the forecast period.

In 2025, the electrical equipment segment is expected to account for the largest share, 48.0%, of the global advanced ceramics market. The segment’s large share is attributed to rising investments in the electronics sector, growing demand for electroceramics, and the increasing need for high-performance and cost-effective electronic equipment.

The growth of this market can be attributed to several factors, increasing adoption of advanced ceramics in the healthcare sector and rising demand for advanced ceramics in the defense sector. Moreover, the increasing use of nanotechnology and the growing adoption of advanced ceramics in the automotive sector are expected to offer growth opportunities for the players operating in this market.

The key players operating in the global advanced ceramics market are KYOCERA Corporation (Japan), CeramTec GmbH (Germany), CoorsTek, Inc. (U.S.), Morgan Advanced Materials plc (U.K.), AGC Inc. (Japan), Elan Technology (U.S.), 3M Company (U.S.), MARUWA CO., LTD. (Japan), Ortech Inc. (U.S.), Saint Gobain Ceramic Material (U.S.), Advanced Ceramic Materials (U.S.), McDanel Advanced Material Technologies (U.S.), BCE Special Ceramics GmbH (Germany), STC Material Solutions (U.S.), and Technocera Industries (India).

At present, North America dominates the advanced ceramics market. However, Japan, China, India, and South Korea are expected to witness strong growth in demand for advanced ceramics in the coming years.

Published Date: Apr-2024

Published Date: Aug-2017

Published Date: Jan-2024

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates