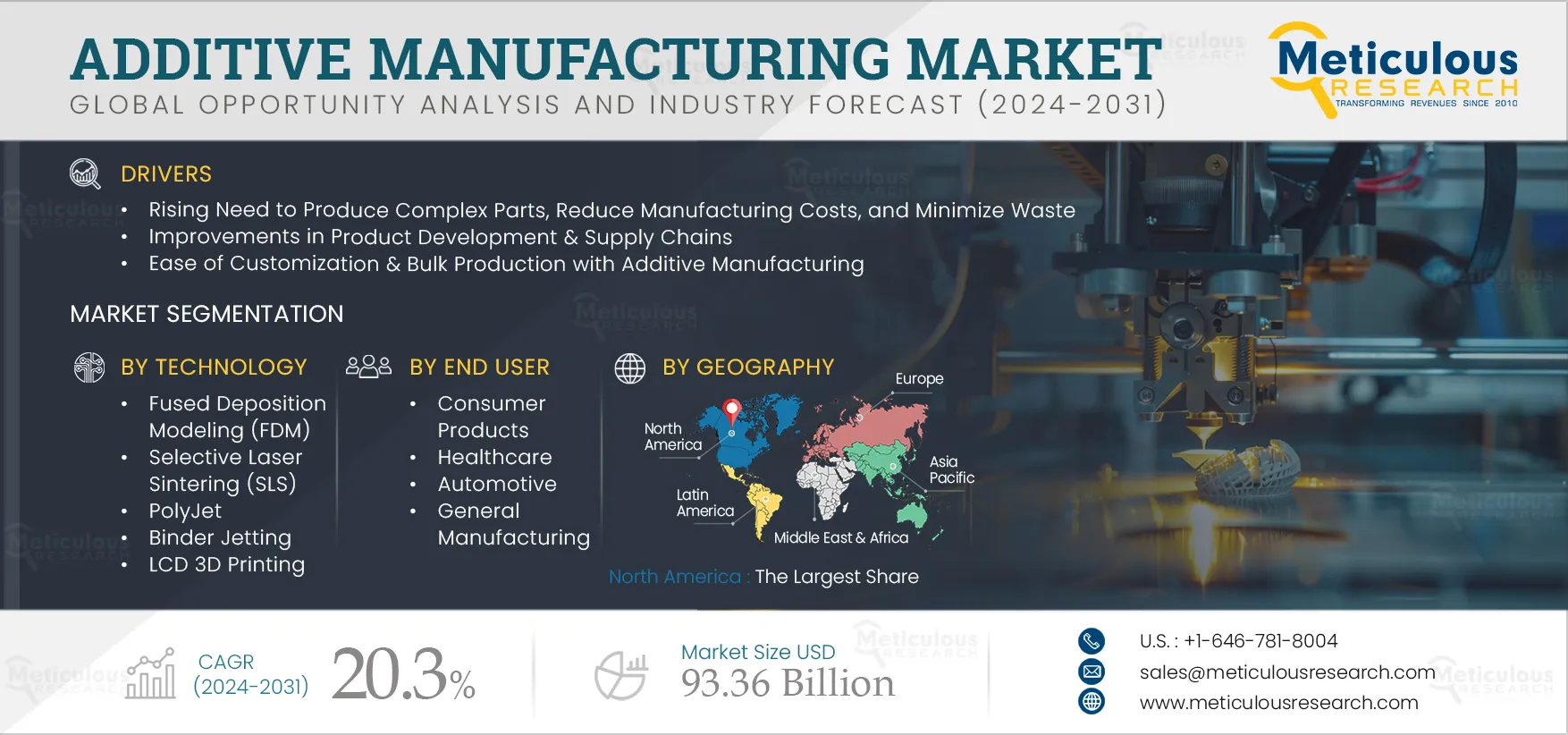

The Additive Manufacturing Market is expected to grow at a CAGR of 20.3% from 2024 to 2031 to reach $93.36 billion by 2031. The growth of the additive manufacturing market is driven by the rising need to produce complex parts, reduce manufacturing expenses, and minimize waste, improvements in product development and supply chains, and easy customization and bulk production using additive manufacturing. Furthermore, the growing use of 3D printers to produce functional end-use parts, composite 3D printing, increasing use of 3D printing in regenerative medicine, and increasing spending in aerospace & defense is expected to offer significant growth opportunities for players operating in the additive manufacturing market.

However, restricted build size & material constraints and high pre-processing and post-processing costs may restrain the growth of this market. In addition, concerns about piracy & unauthorized distribution, scarcity of skilled professionals, high initial investment requirements, and maintaining consistent quality are the major challenges for the growth of this market.

Here are the top 10 companies operating in the Additive Manufacturing Market

Founded in 1989 and with dual headquarters in Minnesota, U.S., and Rehovot, Israel, Stratasys, Ltd. develops polymer-based 3D printing solutions for industries such as aerospace, automotive, transportation, healthcare, consumer products, dental, medical, fashion, and education. The company is primarily engaged in providing polymer 3D printing solutions with a portfolio of 3D printing platforms, software, materials, and technology.

The company operates through one reportable segment, which generates revenue from the sales of 3D printing systems, related services, consumables, and additive manufacturing solutions. As of December 2023, the company had approximately 2,600 granted and pending technology patents. The company constantly strives for innovations in 3D printing. To advance its 3D printing technologies, the company invested in the merger of its former subsidiary MakerBot (previously a fully owned subsidiary, divested in 2022) with Ultimaker (Netherlands) to form a new combined desktop 3D printing company. After this acquisition, the company owns a 46.5% stake in Ultimaker (Netherlands).

The company has a direct presence in Israel, the U.S., Germany, Hongkong, China, India, Korea, Brazil, Mexico, the U.K., Denmark, the Netherlands, and Japan through offices, manufacturing sites, and warehouses. As of December 2023, the company had installed more than 35,000 printers. Some of the company’s subsidiaries operating in the additive manufacturing market are Stratasys, Inc. (Delaware), Stratasys Direct, Inc. (U.S.), Stratasys AP Limited (Hong Kong), Stratasys Japan Co. Ltd. (Japan), Stratasys Shanghai Ltd. (China), Stratasys GMBH, (Germany), and Stratasys Latin America Representacao De Equipamentos Ltd. (Brazil).

3D Systems Corporation (U.S.)

Founded in 1986 and headquartered in South Carolina, the U.S., 3D Systems Corporation manufactures and sells 3D printers, 3D printing materials, 3D printed parts, software, and digital design tools. The company has two reportable business segments: Healthcare Solutions and Industrial Solutions. The company offers solutions for aerospace, automotive, consumer technology, foundry, jewelry, semiconductor, transport, turbo machinery, dental, medical, and bioprinting applications within the industrial and healthcare segments. The company operates in the additive manufacturing market through both business segments. The company offers 3D printers for plastics and metals, materials, software, and digital design tools in the additive manufacturing market.

The company has a geographical presence in the U.S., Europe, the Middle East, and Africa (EMEA), and Asia–Pacific (APAC) through its subsidiaries, R&D sites, manufacturing and distribution sites, and administrative support. Some of the major subsidiaries are 3D Systems GmbH (Germany), Kumovis GmbH (Germany), Oqton Belgium N.V. (Belgium), Phenix Systems (France), 3D Canada Company (Canada), 3D European Holdings Ltd. (U.K.), and 3D Holdings, LLC (U.S.).

Founded in 1989 and headquartered in Bavaria, Germany, EOS GmbH provides additive manufacturing solutions. Its metal 3D printers are available in various formats, from entry-level models to multi-laser machines for additive series production at industrial scales.

The company offers additive manufacturing 3D systems, materials, and process parameters. The company is ISO 9001:2015 and ISO 14001: 2015 certified. EOS has a presence in South Africa, China, India, Singapore, Japan, Israel, Turkey, Australia, Finland, France, Germany, Italy, Sweden, the U.K., Italy, the U.S., and Canada through offices and sales partners. The company has more than 1,300 employees globally.

Colibrium Additive (Subsidiary of General Electric Company ) (U.S.)

Founded in 2016 and headquartered in Massachusetts, the U.S., Colibrium Additive specializes in additive manufacturing and designs and manufactures complex parts. The company focuses on advanced additive manufacturing technologies to produce 3D printed parts for a wide range of industries, including aerospace, automotive and automobiles, medical research, and industrial sectors.

Formerly known as GE Additive, Colibrium Additive is a subsidiary of General Electric Company and operates through the Aerospace business segment of General Electric Company (U.S.). The company provides printers based on laser, electron beam, and binder jet technologies and powders for the additive manufacturing market.

The company has a geographical presence in 160 countries throughout the U.S., Europe, Middle East, and Africa (EMEA), Asia, China, and the Americas through its subsidiaries, R&D sites, manufacturing sites and distribution, and administrative support. The company has service operations in 59 manufacturing plants located in 24 states in the U.S. and Puerto Rico and at 102 manufacturing plants located in 25 other countries. Some of the major subsidiaries are Sandvik AB (Sweden), Arcam AB (Sweden), Concept Lazer (Germany), and Advanced Powders & Coatings (Canada).

Founded in 1990 and headquartered in Leuven, Belgium, Materialise NV provides additive manufacturing and medical software tools and 3D printing services. Materialise offers products and services to industries such as aerospace, architecture, automotive, biomechanics & orthotics, CAD/PLM, consumer goods, eyewear, healthcare, machinery & equipment, and service bureaus & contract manufacturers. The company operates in three business segments: Materialise Software, Materialise Medical, and Materialise Manufacturing. The company operates in the additive manufacturing market through all segments by providing additive manufacturing materials and software.

The company has a geographical presence in 21 countries through lease other service centers, sales offices, and manufacturing sits in Australia, Brazil, China, Colombia, France, Germany, Poland, Japan, Malaysia, Ukraine, the U.K., Austria, and the U.S. As of December 2023, the company issued 476 patents and an additional 101 pending patent applications, primarily in the U.S., Japan, and the European Union. Some of the subsidiaries operating in the additive manufacturing market are Materialise SAS (France), Materialise GmbH (Germany), Materialise Japan K.K. (Japan), Materialise USA, LLC(U.S.), Materialise SA (Poland), Materialise Shanghai Co. Ltd (China), Materialise Australia PTY Ltd (Australia), and Materialise S.R.L. (Italy).

Desktop Metal, Inc. (U.S.)

Incorporated in 2015 and headquartered in Massachusetts, U.S., Desktop Metal, Inc. provides a new generation of additive manufacturing technology solutions. The company operates through one reportable segment with a portfolio of software, hardware, materials, and services and also provides metals, polymers, elastomers, ceramics, sands, composites, and biocompatible materials.

The company has a geographic presence in over 40 countries around the world. As of December 2023, it had over 1,000 patents or pending patent applications. Some of the company’s subsidiaries operating in the additive manufacturing market are EnvisionTEC, Inc. (U.S.), Adaptive 3D Holdings, Inc. (U.S.), Aerosint SA (Belgium), Dental Arts Laboratories, Inc. (U.S.), Dental Arts Laboratories, Inc. (U.S.), and Larry Brewer Dental Lab, Inc. (U.S).

Founded in 1999 and headquartered in Bavaria, Germany, voxeljet AG manufactures 3D printing systems and on-demand parts & services for commercial and industrial customers. The company offers 3D printing systems to various industries, such as the automotive, art and architecture, aerospace, engineering, and consumer product end markets. The company operates in two business segments: Systems and Services. Voxeljet operates in the additive manufacturing market through its Systems segment by providing 3D printers. The Systems segment includes all consumables, spare parts, and maintenance related to systems.

The company has a direct presence in 26 countries through its offices, production sites, and manufacturing facilities in the U.S., Austria, Italy, Spain, Poland, Hong Kong, Japan, South Korea, Egypt, Israel, Saudi Arabia, Turkey, Portugal, and Taiwan. Also, the company has on-demand service centers on three continents. As of December 2022, the company installed a base of 224 printers all over the world. Some of its subsidiaries operating in the additive manufacturing market are voxeljet America Inc. (U.S.) and voxeljet India Pvt. Ltd (India), voxeljet China Pvt. Ltd. (China), and voxeljet UK Ltd (U.K.).

Optomec, Inc. (U.S.)

Founded in 1982 and headquartered in New Mexico, the U.S., Optomec, Inc., is an additive manufacturing company. It has worked with industrial companies and research organizations to deliver 3D printing. Optomec sells its products in markets such as electronics, energy, life sciences, aerospace and defense, and the Internet of Things (IoT). The company operates in the additive manufacturing market by providing 3D-printed metals and software.

The Optomec customer base includes industrial, research and government organizations such as General Electric, National Renewable Energy Laboratory (NREL), United Technologies, Boeing, Xerox, multiple Fraunhofer Institutes (IFAM, IKTS, ENAS, IWS, ISE), CEA LETI, IMEC, PeTeC, Sirris, NASA, Sandia National Laboratories, and the US Air Force, US Army, and US Navy.

Optomec has a presence in multiple countries through its distributors and offices in the U.S., Australia, India, Taiwan, Ireland, the U.K., Turkey, China, Italy, Ireland, Germany, Austria, Switzerland, Denmark, Switzerland, Denmark, France, Spain, Portugal, Japan, Korea, and Canada. The company has an international capital markets division that operates in Canada, the U.S., the U.K., France, Ireland, Hong Kong, China, Singapore, Australia, and Barbados. The company is ISO 9001 certified.

Founded in 1999 and headquartered in Minnesota, the U.S., Proto Labs, Inc. is a digital manufacturer of custom parts. The company utilizes computer numerical control (CNC) machining, injection molding, 3D printing, and sheet metal fabrication to manufacture custom parts for customers. The company sells its products and services to product developers, engineers, and procurement and supply chain professionals. The company’s operations are comprised of two geographic operating segments: in the U.S. and Europe. Proto Labs. Proto Labs manufacturing product lines include Injection Molding, CNC Machining, 3D Printing and Sheet Metal. The company operates in the additive manufacturing market through a 3D printing product line by providing 3D printing materials.

The company has a direct presence through manufacturing facilities, a manufacturing network, and offices in the U.S., Germany, Netherlands, and the U.K. Some of its subsidiaries operating in the additive manufacturing market are PL-US International LLC (U.S.), Hubs Manufacturing Inc. (U.S.), 3D Hubs Manufacturing LLC (U.S.), Proto Labs Ltd (U.K.), PL International Holdings, UK, Ltd. (U.K.), Proto Labs GmbH (Germany), Proto Labs Tooling GmbH (Germany), and 3D Hubs B.V (Netherlands).

Founded in 1982 and headquartered in California, U.S., Autodesk, Inc. is a software company that operates in 3D design, engineering, and entertainment technology solutions, spanning the architecture, engineering, construction, product design, manufacturing, media, and entertainment industries. The company operates through one reportable segment. The company offers its products in five categories, namely Architecture, Engineering & Construction Collection, AutoCAD and AutoCAD LT, Manufacturing, Media and Entertainment, and others. The company sells its products globally through a combination of indirect and direct channels. The company has a global presence in the Americas, Europe, the Middle East & Africa, and Asia-Pacific. Subsidiaries of the company include Assemble Systems, LLC (U.S.), Autodesk Asia Pte. Ltd. (Singapore), Autodesk France S.A.S. (France), Autodesk GmbH (Germany), Autodesk Holdings LLP (U.K), Autodesk Development B.V. (Netherlands), Autodesk Development S.a.r.l. (Switzerland), Autodesk Ireland Operations Unlimited Company (Ireland), Autodesk Ltd. Japan (Japan), and Autodesk Software (China) Co., Ltd. (China).