Resources

About Us

3D Printing Plastics Market Size, Share, Forecast, & Trends Analysis by Type (Polylactic Acid, Polycarbonate, Polyamide), Form (Filament, Pellets, Powder), Technology (FDM, SLA, SLS), End-use Industry (Manufacturing, Healthcare, Automotive), and Geography - Global Forecast to 2032

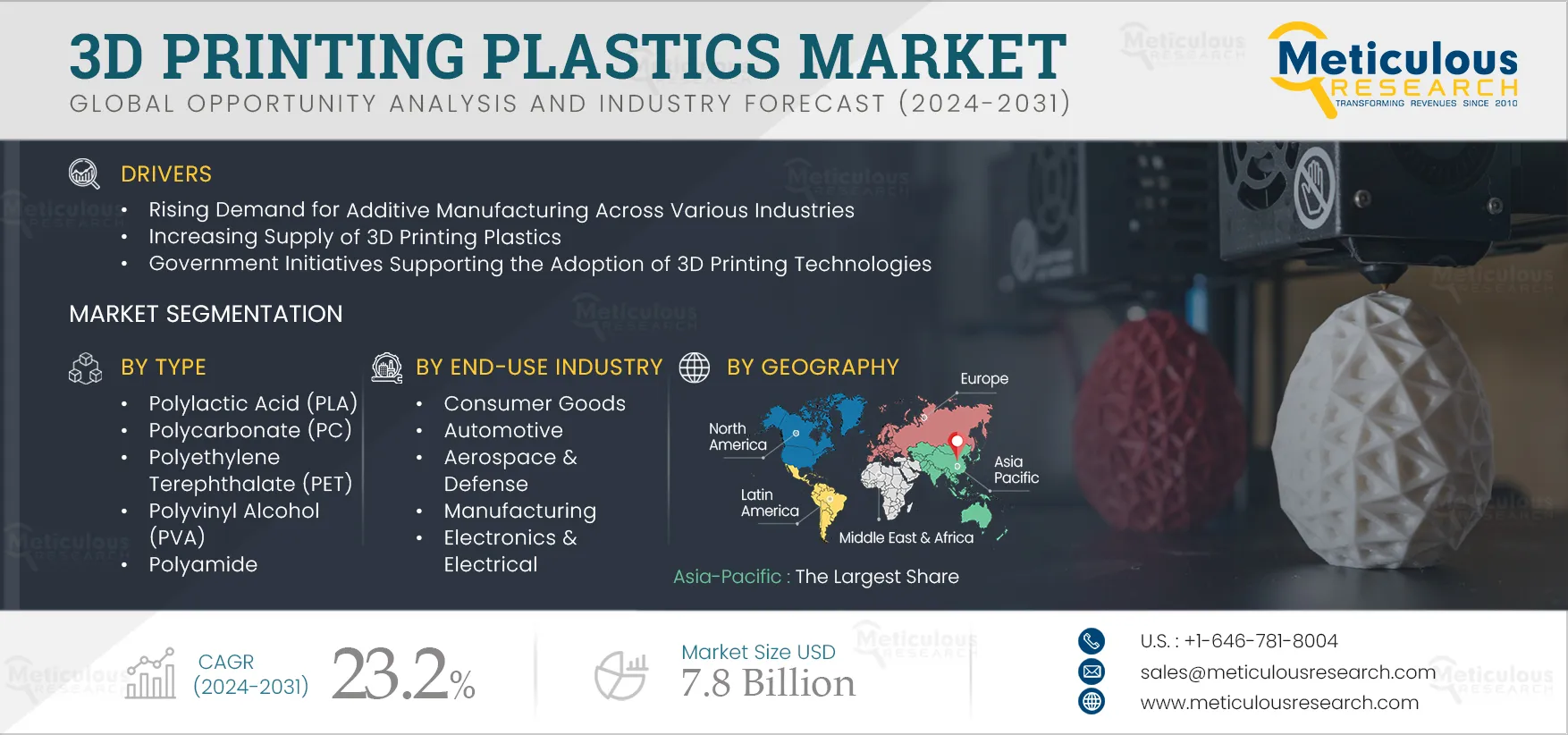

Report ID: MRCHM - 1041267 Pages: 250 Jan-2024 Formats*: PDF Category: Chemicals and Materials Delivery: 24 to 72 Hours Download Free Sample ReportThe 3D Printing Plastics Market is expected to reach $7.8 billion by 2032, at a CAGR of 23.2% from 2025 to 2032. The growth of the 3D printing plastics market is primarily driven by the rising demand for additive manufacturing across various industries, the increasing supply of 3D printing plastics, and government initiatives supporting the adoption of 3D printing technologies. Moreover, advancements in 3D printing technologies and the rising demand for bio-based plastics are expected to generate growth opportunities for the players operating in this market.

The growing demand for additive manufacturing in the production of functional end-use parts is driving the 3D printing plastics market. Additive manufacturing capabilities for producing functional end-use parts have expanded across various industries, including aerospace, automotive, healthcare, and consumer goods. Governments are undertaking initiatives to promote additive manufacturing across industries to enable manufacturers to produce parts that meet stringent performance requirements. In May 2022, the U.S. government launched the Additive Manufacturing Forward (AM Forward) initiative to help smaller U.S.-based businesses produce and sell higher-performing parts, shorten lead firms’ wait times for needed parts, and expand consumers’ access to better products through the use of additive manufacturing.

Also, the development of new materials suitable for 3D printing has been pivotal in enabling the production of functional end-use parts. These materials include plastics that offer a balance of properties such as strength, durability, heat resistance, and chemical resistance, making them suitable for a broad range of applications. As material science continues to evolve, further improvements in the performance and suitability of plastic for end-use parts can be expected. By eliminating the need for tooling, reducing material waste, and streamlining production processes, companies can increase efficiency and reduce production costs. These benefits are increasing the use of additive manufacturing across industries, driving the demand for 3D printing plastics.

Click here to: Get Free Sample Pages of this Report

Governments around the world have recognized the potential of 3D printing technologies and are launching various initiatives to support their adoption. China has witnessed a significant rise in the availability and adoption of 3D printing services. Chinese companies are now turning to 3D printing to create prototypes, customized products, and medical implants. The Chinese government has implemented a series of measures to promote the development of the 3D printing industry in the country. Also, additive manufacturing has gained significant acceptance in the Japanese market, with Japanese companies relying on 3D-printed replacement parts for older models of household appliances and classic cars. In addition, Japan is facing a labor shortage and, therefore, is focused on training its next generation of employees. Hence, the Japanese government is promoting 3D printing technologies among manufacturing companies to overcome mass production and workforce challenges.

Some of the recent government initiatives in the 3D printing space are as follows:

Thus, increasing government initiatives supporting the adoption of additive manufacturing are driving the 3D printing plastics market.

3D printing technology is evolving rapidly, revolutionizing the manufacturing industry. 3D printing technology is in high demand due to its ability to create complex structures with high precision and accuracy. Additionally, new techniques such as bioprinting and 4D printing have created new possibilities in the field of medicine. 3D printing technology has moved beyond the traditional FDM (Fused Deposition Modeling) technique with the emergence of new methods. Techniques such as bioprinting are used in creating human tissues and organs for medical applications.

AI is also becoming increasingly important in 3D printing. AI is used to optimize printing parameters for better results, automate support structure generation, and detect and fix errors in 3D models during the pre-printing stage. Also, in traditional 3D printing, a single filament of plastic material is used. However, advancements in multi-material printing have allowed objects to be crafted with a combination of different plastics within one print. Such advancements are driving the adoption of 3D printing technology creating market growth opportunities.

3D printing has revolutionized the manufacturing of objects and products. Bioplastics have emerged as a sustainable and promising alternative due to environmental concerns. Bioplastics are materials produced from renewable sources and help reduce plastic waste. These materials offer significant advantages, such as reduced greenhouse gas emissions, biodegradability, and lower dependence on fossil fuels. These materials are versatile and are, therefore, used in diverse applications across various industries.

Some of the 3D printing practical applications of bioplastics are as follows:

Such factors are increasing the demand for 3D printing bio-based plastics, generating growth opportunities for the players operating in this market.

Based on type, the 3D printing plastics market is segmented into Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Polycarbonate (PC), Polyethylene Terephthalate (PET), Polyvinyl Alcohol (PVA), polyamide, and other 3D printing plastics. In 2025, the polylactic acid (PLA) segment is expected to account for the largest share of over 33% of the 3D printing plastics market. The large market share of this segment is attributed to the rising demand for bioplastics, favorable government initiatives, the performance benefits of PLA, and the rising adoption of PLA in the healthcare sector. In April 2025, Filamentive Limited (U.K.) launched a PLA 3D Printing waste recycling service to combat plastic pollution caused due to FDM 3D printing.

However, the polyamide segment is projected to register the highest CAGR during the forecast period. The segment's growth is driven by the increasing use of polyamide in the automotive and aerospace sectors due to its high strength, the growing focus on eco-friendly manufacturing solutions, and the increasing use of polyamide in consumer goods manufacturing.

Based on form, the 3D printing plastics market is segmented into filament, pellets, powder, and liquid. In 2025, the filament segment is expected to account for the largest share of over 71% of the 3D printing plastics market. The large market share of this segment is attributed to the growing use of 3D printing filaments for manufacturing commercial and military aircraft and the increasing use of filament materials in prototyping applications. Moreover, several key players are focusing on the development of materials in filament form for the 3D printing of medical implants. For instance, in October 2024, Evonik Industries AG (Germany) launched the 'world's first' carbon-fiber-reinforced PEEK filament for use in 3D-printed long-term medical implants. Moreover, this segment is also projected to register the highest CAGR during the period.

Based on technology, the 3D printing plastics market is segmented into Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and other technologies. In 2025, the fused deposition modeling (FDM) segment is expected to account for the largest share of the 3D printing plastics market. The large market share of this segment is attributed to the increasing use of FDM for small-batch and customized parts production, the increasing use of FDM by educational institutes, and the better affordability and user-friendliness of FDM compared to other technologies. Moreover, this segment is also projected to register the highest CAGR during the period.

Based on end-use industry, the 3D printing plastics market is segmented into consumer goods, automotive, aerospace & defense, manufacturing, electronics & electrical, healthcare, energy, and other end-use industries. In 2025, the manufacturing segment is expected to account for the largest share of over 26% of the 3D printing plastics market. The large market share of this segment is attributed to the growing use of 3D printing for mass production in industrial manufacturing, the increasing focus of manufacturers on reducing costs and lead times, and the increasing use of 3D-printed composite materials in manufacturing applications. In November 2024, Velo3D, Inc. (U.S.) announced that Atomic Industries (U.S.) purchased a fully integrated metal additive manufacturing solution to provide its customers with 3D-printed tooling and dies.

However, the healthcare segment is projected to register the highest CAGR during the period. The segment's growth is driven by the increasing use of 3D printing plastics for creating personalized medical devices, advancements in 3D printing materials, and the increasing development of biocompatible plastics for 3D printing of implants, scaffolds for tissue regeneration, and custom-made drugs.

In 2025, Asia-Pacific is expected to account for the largest share of over 42% of the 3D printing plastics market. Asia-Pacific’s large market share is attributed to increased R&D funding, the growing adoption of Industry 4.0, the growing utilization of 3D printing technologies in the healthcare, construction, and education sectors, and increasing government-led strategies & policies supporting the adoption of 3D printing technologies. Moreover, this region is also projected to record the highest CAGR of over 25% during the forecast period. In May 2021, Farsoon Technologies Co., Ltd (China) partnered with Japan 3D Printer Co., Ltd. (Japan) to expand its business in Japan. The company installed Farsoon’s high-temperature HT403P 3D printer at Japan 3D Printer’s Demo Center to offer industrial SLS technology.

The report offers a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3 to 4 years. The key players operating in the 3D printing plastics market include 3D Systems Corporation (U.S.), Evonik Industries AG (Germany), Arkema (France), SABIC (Saudi Arabia), Stratasys Ltd. (U.S.), Materialise nv (Belgium), CRP TECHNOLOGY S.r.l. (Italy), Formlabs Inc. (U.S.), HP Development Company, L.P. (U.S.), Dassault Systemes (France), Proto Labs, Inc. (U.S.), EOS GmbH (Germany), Avient Corporation (U.S.), Henkel AG & Co. KGaA (Germany), and Huntsman International LLC (U.S.).

3D Printing Plastics Industry Overview: Latest Developments from Key Industry Players

In June 2024, Procter & Gamble (Hong Kong) and Watsons (Hong Kong) partnered with MakerBay Foundation Limited (Hong Kong) to repurpose and transform plastics into 3D printing materials suitable for use in general primary and secondary schools.

In June 2022, 3D Systems, Inc. (U.S.) signed a Memorandum of Understanding (MoU) with AIPMA (India) to promote the use of additive manufacturing in the plastics industry.

|

Particulars |

Details |

|

Number of Pages |

250 |

|

Format |

|

|

Forecast Period |

2025–2032 |

|

Base Year |

2024 |

|

CAGR (Value) |

23.2% |

|

Market Size (Value) |

$7.8 Billion by 2032 |

|

Segments Covered |

By Type

By Form

By Technology

By End-use Industry

|

|

Countries Covered |

North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Russia, Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Rest of Asia-Pacific), Latin America (Mexico, Brazil, Rest of Latin America), and the Middle East & Africa (UAE, Israel, Rest of Middle East & Africa) |

|

Key Companies Profiled |

3D Systems Corporation (U.S.), Evonik Industries AG (Germany), Arkema (France), SABIC (Saudi Arabia), Stratasys Ltd. (U.S.), Materialise nv (Belgium), CRP TECHNOLOGY S.r.l. (Italy), Formlabs Inc. (U.S.), HP Development Company, L.P. (U.S.), Dassault Systemes (France), Proto Labs, Inc. (U.S.), EOS GmbH (Germany), Avient Corporation (U.S.), Henkel AG & Co. KGaA (Germany), and Huntsman International LLC (U.S.) |

The 3D printing plastics market study focuses on market assessment and opportunity analysis based on the sales of 3D printing plastics across different regions, countries, and market segments. This study also includes a competitive analysis based on an extensive assessment of the leading players’ product portfolios, geographic presence, and key growth strategies adopted in the last 3 to 4 years.

The 3D printing plastics market is projected to reach $7.8 billion by 2032, at a CAGR of 23.2% during the forecast period.

In 2025, the polylactic acid (PLA) segment is expected to account for the largest share of over 33% of the 3D printing plastics market.

Based on end-use industry, the healthcare segment is projected to register the highest CAGR during the forecast period.

The growth of the 3D printing plastics market is primarily driven by the rising demand for additive manufacturing across various industries, the increasing supply of 3D printing plastics, and government initiatives supporting the adoption of 3D printing technologies. Moreover, advancements in 3D printing technologies and the rising demand for bio-based plastics are expected to generate growth opportunities for the players operating in this market.

The key players operating in the 3D printing plastics market include 3D Systems Corporation (U.S.), Evonik Industries AG (Germany), Arkema (France), SABIC (Saudi Arabia), Stratasys Ltd. (U.S.), Materialise nv (Belgium), CRP TECHNOLOGY S.r.l. (Italy), Formlabs Inc. (U.S.), HP Development Company, L.P. (U.S.), Dassault Systemes (France), Proto Labs, Inc. (U.S.), EOS GmbH (Germany), Avient Corporation (U.S.), Henkel AG & Co. KGaA (Germany), and Huntsman International LLC (U.S.).

Asia-Pacific is projected to register the highest CAGR of over 25% during the forecast period.

Published Date: Apr-2024

Published Date: Jun-2021

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates