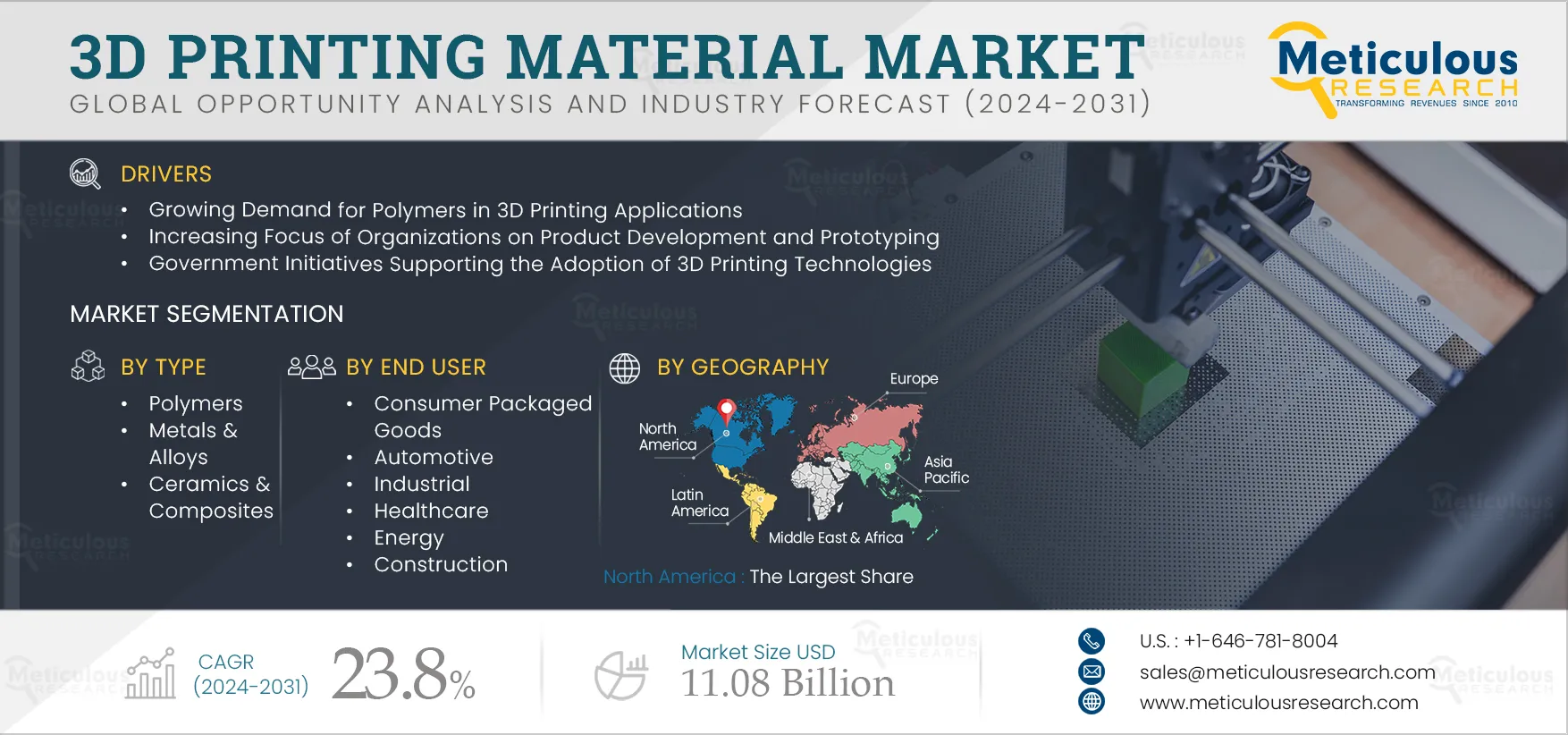

3D Printing Materials Market is expected to reach a value of $11.08 billion by 2031, at a CAGR of 23.8% during the forecast period 2024-2031. 3D printing technology has been evolving faster than other manufacturing technologies as it can influence manufacturing processes and help businesses perform to a higher level. Further, 3D printing manufacturing line is easier to alter than the production line for traditional manufacturing. This makes it preferable for the bulk equipment manufacturing processes. Due to this advantage, industries such as aerospace, construction, and automotive have started adopting this technology aggressively. On the other hand, healthcare and electronics manufacturers are some of the earliest adopters of 3D printing, owing to its advantages such as faster time-to-market, design flexibility, and capabilities of manufacturing customized products. Thus, in the last few years, huge market demand for 3D printing materials were observed in healthcare.

Here are the top 10 companies operating in the 3D Printing Materials Market

Stratasys, Ltd.

Founded in 1989 and headquartered at Rehovot, Israel, Stratasys, Ltd. is a global leader in additive manufacturing or 3D printing technology and is the manufacturer of FDM and PolyJet3D Printers. The company operates through three major divisions, namely prototypes, manufacturing tools, and production parts for industries, including aerospace, automotive, healthcare, consumer products, and education, among others.

Stratasys systems are used by engineers to model complex geometries in a wide-ranging of thermoplastic materials comprising of Acrylonitrile Butadiene Styrene (ABS), Polyphenylsulfone (PPSF), Polycarbonate (PC), and ULTEM 9085 and Nylon 12. It offers products and services and operates in the 3D printing materials market through its polymers and metals product segment.

Some of the major subsidiaries of the company are MakerBot (New York), GrabCAD (U.S), Stratasys GmBh (U.S), Solid concepts (U.S), Objet Geometries (Israel), etc. The company has its geographic presence in Brazil, China, Germany, Hong Kong, Israel, Japan, Korea, India, Mexico, the U.K. and the U.S.

The Hewlett Packard Company

Founded in 1939 and headquartered at California, the U.S., HP Inc. is a leading global provider of personal computing and other access devices, imaging and printing products, and related technologies, solutions, and services. HP sells its products to individual consumers, small- and medium-sized businesses (SMBs), and large enterprises, including customers in the government, health and education, and other sectors. HP specialized in developing and manufacturing computing, data storage, and networking hardware; designing software; and delivering services.

The major product range include personal computing devices, enterprise and industry standard servers, related storage devices, networking products, software, and a diverse range of printers and other imaging products. HP also has services and consulting business around its products and partner products. 3D printing delivers the HP multi-jet fusion 3D printing solution designed for prototyping and production of functional parts and functions on an open platform facilitating the development of new 3D printing materials. The company operates in the 3D printing materials market through its printing segment.

The company has its geographic presence primarily in Americas, Europe, Middle East and Africa, and Asia-Pacific regions. Some of the major subsidiaries of the company are VoodooPC (Canada), Apogee corporation (U.K.), PrinterOn Corporation (Canada), Hewlett-Packard India Sales Private Limited (India), Indigo America, Inc. (U.S.), and Avantek Inc. (U.S.), among others.

EOS GmbH

Headquartered at Germany, EOS GmbH is a global technology leader for industrial 3D printing of metals and polymers. EOS is known for being an inventor and innovator for complete solutions in additive manufacturing. EOS is grasping the interaction of laser and powder material. Moreover, EOS offers all the necessary elements for industrial 3D printing.

The company has its geographic presence in Africa, Asia, America, Europe, and Russia. Some of the major subsidiaries of the company are Advanced Laser Materials LLC (U.S.), Kvg Kunststoff-Vertriebs Kg (Germany), and others.

3D Systems, Inc.

Founded in 1986 and headquartered at South Carolina, the U.S., 3D Systems, Inc. is a leading additive manufacturing solutions company. It empowers manufacturers to create products and business models. This is succeeded with the company’s finest digital manufacturing ecosystem consist of plastic and metal 3D printers, print materials, on demand manufacturing services, and a portfolio of end-to-end manufacturing software.

The company operates in advanced applications for prototyping through production in markets such as aerospace, automotive, medical, dental, and consumer goods. The company operates in 3D printing materials market through its material business segment.

The company has its geographic presence in the Americas, EMEA, and APAC regions. Some of the major subsidiaries of the company are Simbionix Ltd. (Israel), Geomagic (U.S), and Cimatron Group (Israel), among others.

The ExOne Company

Founded in 2005 and headquartered at Pennsylvania, the U.S., The ExOne Company is a global provider of 3D printing machines, materials, and services to industrial customers. ExOne’s business mainly comprises of manufacturing and selling of 3D printing machines and printing products according to customer requirement. ExOne can 3D print metal, sand, ceramics, and composites, as well as other powder particles.

From aerospace and automotive to energy and defense, companies in wide range of industries use ExOne 3D printers. The company operates in the 3D printing materials market through its 3D printed material business segment.

The company has its geographic presence in North America, Europe, and Asia regions. Some of the major subsidiaries of the company are ExOne Americas LLC (US), ExOne GmbH (Germany), ExOne KK (Japan), Troy Metal Fabricating LLC (US), ExOne Italy Srl (Italy).

Proto Labs, Inc.

Founded in 1999 and headquartered at Minnesota, the U.S., Proto Labs, Inc. engaged in rapid manufacturing of low-volume 3D printed, CNC-machined, sheet metal, and injection-molded custom parts for prototyping, short-run, and on-demand production. The technology supports company to produce custom parts and assemblies in 1 day with automated 3D printing processes. Their digital method for manufacturing allows accelerated time to market, decreases development and production costs, and reduces risk throughout the product life cycle.

The company offers its products to industries like electronics, appliances, medical devices, automotive, and consumer products. The company operates in 3D printing materials market through its 3D printing business segment.

With its subsidiaries and a strong network of distribution, the company operates in the North America, Europe, and Asia-Pacific. Some of the major subsidiaries of the company are Rapid Manufacturing Group LLC (U.S), Rapid Sheet Metal LLC (U.S), N.H. Rapid Machining, LLC (U.S), and others.

Materialise NV

Founded in 1990 and headquartered at Leuven, Belgium, Materialise N.V. is active in the field of additive manufacturing. The company provides 3D imaging software solutions to develop products for industrial, medical, and dental industries. The company offers design software and prototype solutions to various industries around the world.

The company has a large installed base of various additive technologies that can process a wide range of materials, both polymer and metal. In-house processes include: Stereolithography, Selective Laser Sintering, Fused Deposition Modelling, PolyJet, Multi-Jet Fusion (MJF), and Direct Metal Laser Sintering.

The company has its geographic presence in the Americas, Europe & Africa, and Asia-Pacific regions. Some of the major subsidiaries of the company are Meridian Technique Limited (U.K.), RapidFit+ (Belgium), Meridian Technique Limited (U.K.), and ACTech, Inc. (Taiwan), among others.

Evonik Industries AG

Founded in 2007 and headquartered at Essen, Germany, Evonik Industries AG is a leading specialty chemicals provider, owned by RAG Foundation. Evonik Industries combined the business areas of chemicals, energy, and real estate of RAG, while mining operations continue to be carried out by RAG. Its specialty chemicals business segment generates around 80% of sales in areas in which it holds leading market positions.

Evonik is the main sponsor of German football club Borussia Dortmund. The company operates in the 3D printing materials market through its performance materials business segment.

The company has its geographic presence primarily in Middle East & Africa, Asia-Pacific, America, and Europe. Some of the major subsidiaries of the company are Evonik Degussa (Germany), Evonik-Cyro (US), Evonik Tego Chemie GmbH (Germany), Porphyrio NV (Belgium), and Evonik Nutrition & Care GmbH (Germany), among others.

Arkema S.A.

Founded in 2004 and headquartered at Colombes, France, Arkema S.A is a global manufacturer of specialty chemicals and advanced materials. It operates via three business segments, namely High Performance Materials, Industrial Specialties, and Coating Solutions. Arkema offers innovative solutions in photocure resins and high performance thermoplastic polymers for the 3D printing market.

The company operates in the 3D printing materials market through advance material segment.

Arkema operates in close to 55 countries including China, Japan, U.S, and Canada, among others. Some of the major subsidiaries of the company are Bostik (US), ArrMaz Custom Chemicals, Inc. (Florida), CECA (France), and Altuglas International (France), among others.

Zortrax

Founded in 2013 and headquartered at Olsztyn, Poland, Zortrax is a Polish developer of a wide-range of 3D printing solutions , including 3D printers, filaments, Z-SUITE software, and other devices. Zortrax offer its products to thousands of customers around the world in a wide range of industries, such as architecture, medicine, automotive, engineering, industrial prototyping, or fashion.

Zortrax offers its products through a network of over 130 partners operating in 90 countries around the world on six continents, including the largest markets in Europe, the Americas, Asia, Africa, and Australia.

Popular Mentions: EnvisionTEC Inc., (U.S), Markforged Inc., (U.S), Sculpteo- a BASF Company (France), and Tethon 3D (U.S)