Resources

About Us

3D Printing Construction Market by Construction Method (Extrusion and Powder Bonding), Material Type (Concrete, Metal, Composite and Others), Application (Building & Infrastructure) and Geography—Global Forecasts to 2032

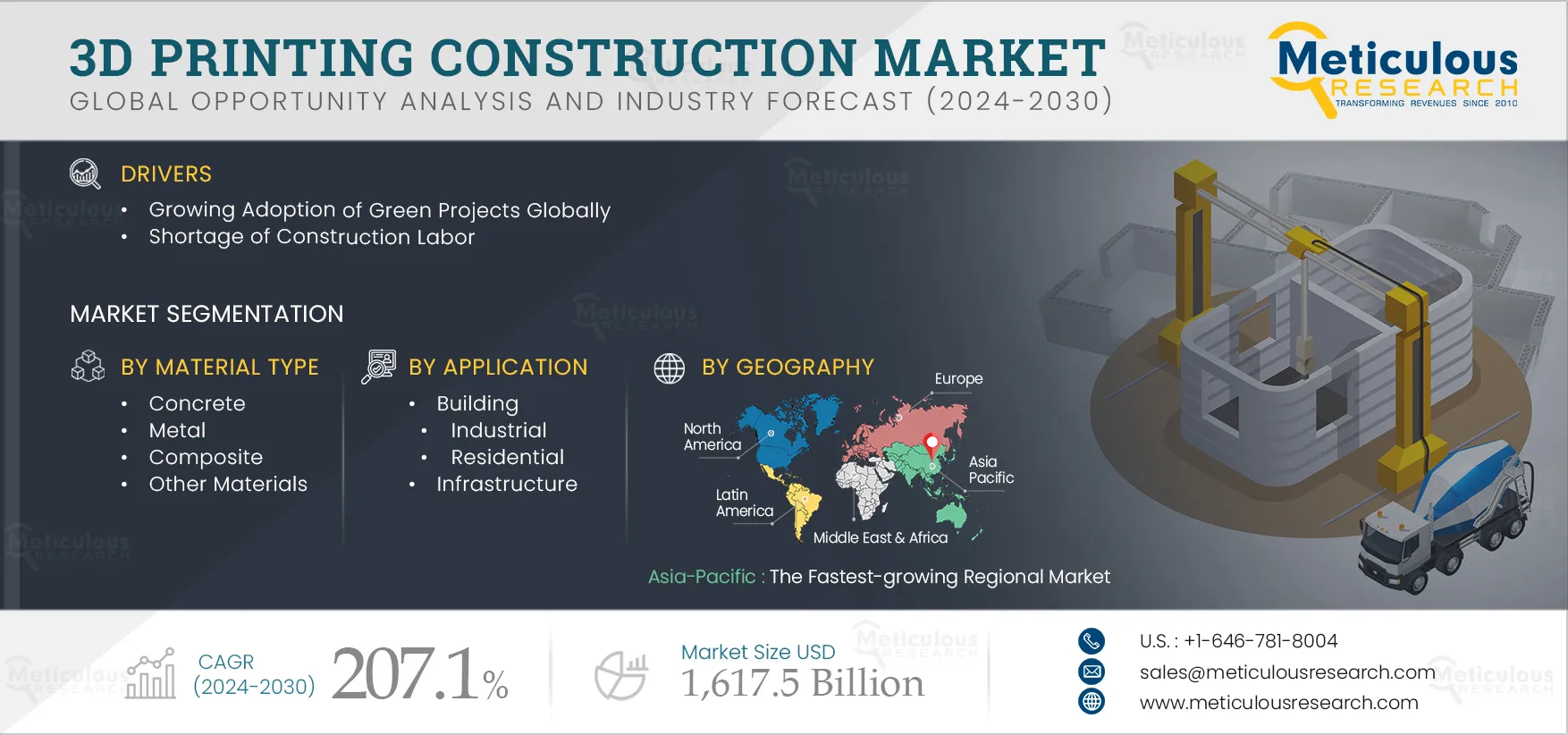

Report ID: MRICT - 104766 Pages: 310 Jan-2025 Formats*: PDF Category: Information and Communications Technology Delivery: 24 to 72 Hours Download Free Sample ReportSome of the major factors driving the growth of this market include low-waste construction, reduced health and safety hazards, increased accuracy, a high level of design freedom, the growing adoption of green projects, and the shortage of construction labor. In addition, growing urbanization in emerging countries and increasing research and development funding for 3D printing technology are expected to offer significant opportunities for the growth of this market. However, high capital investment can restrain the growth of this market to some extent.

Governments worldwide imposed countrywide lockdowns to control the spread of COVID-19. The lockdown restrictions impacted manufacturing operations, with production facilities either completely shutting down or running at reduced capacities to ensure social distancing and employee safety. Most industries came to a standstill due to raw material & workforce shortages, supply chain disruptions, and restrictions on international trade. The pandemic impacted many businesses, including 3D printing construction. As construction activity came to a standstill, there was a significant decline in new house sales.

Nationwide lockdowns and restrictions on activity to contain COVID-19 disrupted supply chains and affected the 3D printing building construction market. Manufacturing of 3D printing machines and supply of construction materials used to construct 3D structures were affected, as facilities were shut down and the movement of people and goods was restricted. On the other hand, the COVID-19 outbreak opened up potential growth opportunities in the 3D printing technology market. In 2020, WinSun, a Chinese construction 3D printing company, deployed 3D-printed isolation wards for the medical staff. Due to the significant development post-pandemic, the 3D printing construction market has shown significant recovery and is expected to witness high growth during the forecast period.

Click here to: Get a Free Sample Copy of this report

The construction industry suffers from a severe human capital shortage, ranging from field labor to management. According to the 2020 AGC Construction Outlook Survey, around 81% of construction companies reported having difficulty finding professionals to fill hourly and salaried positions. The immediate consequences of this shortage can be seen in troubled projects, struggling businesses, and rising insurance claims. Due to the lack of skilled laborers on job sites, it’s taking more time for structures to be completed, with some projects being canceled altogether.

Investing in new technologies, such as 3D printing, to assist the current workforce in increasing collaboration, improving communication, and streamlining efficiencies can solve the labor shortage problem in the construction industry. The use of 3D printing in construction can reduce costs and speed up project schedules by producing less waste, minimizing the use of material resources, increasing accuracy, and freeing up labor for other tasks. Several construction companies started using 3D printing technology to handle the construction labor shortage. For instance, in 2020, Germany-based construction company PERI Group announced the beginning of a project which will see the construction of a three-floor printed commercial apartment building on-site in Wallenhausen, Germany. Thus, the rising adoption of 3D printing in construction to deal shortage of labor is expected to drive market growth.

Based on construction method, the 3D printing construction market is segmented into extrusion, powder bonding and spray. In 2025, the extrusion segment is expected to account for the largest share of the global 3D printing construction market. Extrusion is the most common 3D printing technique, as it can be used in almost all environments. Commonly used for modeling, prototyping, and production applications, this method creates an object by layering material through one or more nozzles mounted on a robotic arm, gantry system or crane. Growth of the segment is attributed to the factors such as flexibility of operation, easy post-execution alterations, continuous operation, and high production volumes. However, the powder bonding segment is projected to register the highest CAGR during the forecast period.

Based on material type, the 3D printing construction market is segmented into concrete, metal, composite, and others. In 2025, the concrete segment is expected to account for the largest share of the global 3D printing construction market. 3D concrete printing is increasingly being used as an alternative to conventional concrete construction owing to its potential to reduce cost, labor, and time and increase overall productivity. However, with the use of 3D-printed concrete formworks, it is possible to create double-curved surfaces and organic geometry at a fraction of the cost. Owing to these benefits, constructors are focused on developing 3D-printed concrete formwork. However, the metal segment is expected to record the fastest growth rate throughout the forecast period.

Based on geography, the market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2025, Asia-Pacific is expected to account for the largest share of the 3D printing construction market. The large share of the region is attributed to the rising number of new buildings and growing investment in infrastructure projects. As the region is establishing itself as a global manufacturing hub, the technology is anticipated to gain significant traction over the forecast period. China and Japan are prominent countries with the potential to offer extensive opportunities for emerging and matured technologies, such as 3D printing construction.

The report includes a competitive landscape based on an extensive assessment of the key growth strategies adopted by the leading market participants in the 3D printing construction market between 2020 and 2022. The key players profiled in the 3D printing construction market report are COBOD (Denmark), Yingchuang Building Technique (China), XtreeE (France), Apis Cor Inc. (U.S.), WASP S.r.I (Italy), CyBe Construction (Netherlands), Sika AG (Switzerland), MX3D (Netherlands), Contour Crafting Corporation (U.S.), ICON Technology, Inc. (U.S.), and Constructions-3D (France).

Scope of the report:

The global 3D printing construction market is projected to reach $1,617.5 billion by 2032 at a CAGR of 207.1% during the forecast period.

The growth of this market is mainly driven by the factors such as the rising use of 3D printing in the construction sector, the growing adoption of green projects globally, shortage of construction labor.

The key players operating in the 3D printing construction market are COBOD (Denmark), Yingchuang Building Technique (China), XtreeE (France), Apis Cor Inc. (U.S.), WASP S.r.I (Italy), CyBe Construction (Netherlands), Sika AG (Switzerland), MX3D (Netherlands), Contour Crafting Corporation (U.S.), ICON Technology, Inc. (U.S.), L&T Construction (India) and Constructions-3D (France).

Published Date: Apr-2025

Published Date: Feb-2025

Published Date: Feb-2025

Published Date: Feb-2025

Please enter your corporate email id here to view sample report.

Subscribe to get the latest industry updates