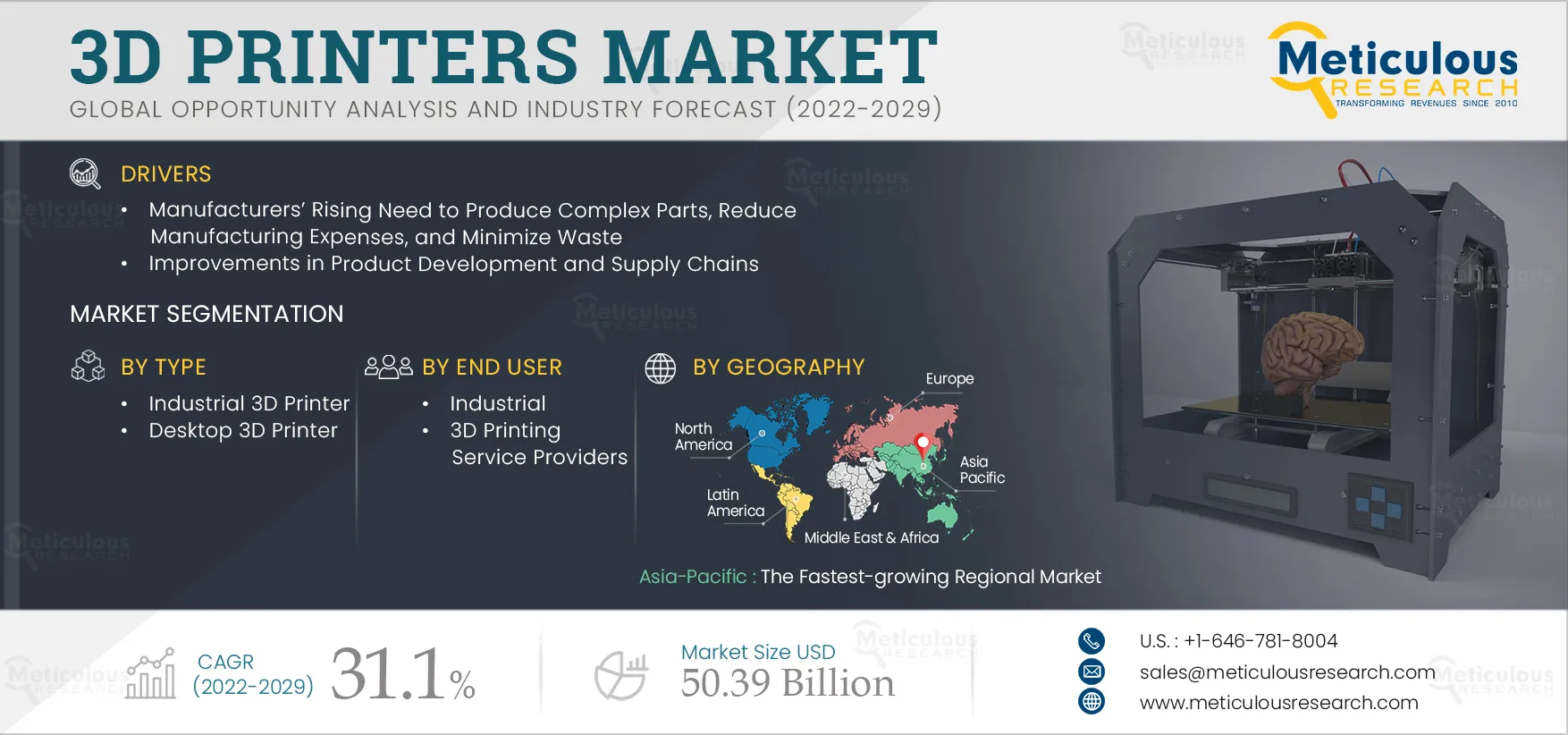

The 3D Printers Market is expected to reach a value of $50.39 billion by 2029, at a CAGR of 31.1% during the forecast period 2022–2029. The growth of the 3D printers market is mainly attributed to the rising demand for complex parts, reduced manufacturing expense, minimized waste, improvement in product development and supply chain addition, and the usage of 3D printing for functional end-use parts. However, restricted build size and pre and post-processing costs hamper this market’s growth. Additionally, on-demand spare parts production, increased product customization, and the use of AI in 3D printing are prevailing trends in the 3D printers market.

Here are the top 10 companies operating in 3D Printers Market

GE Additive (A Part of General Electric Company) (U.S.)

Founded in 2016 and headquartered in Great Lakes, U.S., GE Additive is a world leader in metal additive design and manufacturing. GE Additive provides solutions in the medical, aerospace, military & defense, space, industrial manufacturing, automotive, and dental industries. The company’s products include machines, powders, AddWorks engineering, and consulting services. Under its Machines product portfolio, GE Additive provides the most advanced products with additive technologies. Arcam EBM and Concept Laser DMLM machines are some of the advanced additive products offered by GE Additive. As of December 2021, the company had a headcount of 168,000 employees globally.

The company has a geographical presence across Europe: Germany, Italy, Sweden and the UK.

HP, Inc. (U.S.)

Founded in 1939 and headquartered in California, U.S., HP is a leading global provider of personal computing and other access devices, imaging & printing products & related technologies, and solutions & services. The company operates in three reportable segments: Personal Systems, Printing, and Corporate Investments. The Printing segment provides consumer and commercial printer hardware, supplies, services, solutions, and scanning devices. Under the Printing segment, HP provides 3D printing and digital manufacturing services that offer a portfolio of additive manufacturing solutions. The company provides 3D printing solutions for aerospace, healthcare, industrial, transportation, automotive, and manufacturing services.

The company has a presence in Africa, Asia-Pacific, the Americas, Europe, and the Middle East. As of October 2021, the company had a headcount of 51,000 employees globally.

TRUMPF GmbH + CO. KG (Germany)

Founded in 1923 and headquartered in Ditzingen, Germany, TRUMPF manufactures electronic components. The company offers laser cutting machines, printing products, drill drivers, slat cleaners, seam lockers, power fasteners, profile nibblers, induction generators, storage systems, automation equipment, and electronics for industrial applications. The industries served by TRUMPF include automotive, construction, sheet metal processing, dental,

electronics, air conditioning & energy technology, aviation & aerospace, machine & systems engineering, medical technology, commercial vehicles & transport, jewelry industry, and tool & mold making. The company’s products include machines & systems, lasers, VCSEL solutions & photodiodes, power electronics, power tools, software, and services.

With more than 70 subsidiaries, the group is represented in every European country, North & South America, and Asia. The company’s production facilities are located in Germany, France, Great Britain, Italy, Austria and Switzerland, Poland, the Czech Republic, the U.S., Mexico, and China. As of June 2021, the company had a headcount of 14,767 employees globally.

DMG Mori Company Limited (Japan)

Established in 1948 and headquartered in Tokyo, Japan, DMG MORI manufactures and markets machine tools and related products. The products offered by DMG MORI include machine tools, automation systems, digital solutions, peripherals, and die & mold machining solutions. As of December 2021, the company had a headcount of 12,000 employees globally.

The company has its development & production bases in Japan, the U.S., China, Germany, Poland, Italy, Russia, and sales & service bases in Japan, Europe, Africa, the Americas, China, and Asia

Renishaw plc (U.K)

Founded in 1973 and headquartered in Wotton-under-Edge, U.K., Renishaw is a global, high-precision metrology and healthcare technology group. The company designs, develops, and delivers solutions and systems that provide unparalleled precision, control, and reliability. The company is also a world leader in the field of additive manufacturing (metal 3D printing).

The products offered by Renishaw serve diverse markets across a wide range of industries, including aerospace, automotive, electronics, energy, heavy industry, medical & healthcare, and precision manufacturing. Renishaw has a presence in 37 countries, with 79 offices located globally. The company’s largest markets are China, the U.S., Japan, and Germany. As of June 2021, the company had a headcount of 4,437 employees globally.

3D Systems Corporation (U.S.)

Founded in 1986 and headquartered in Carolina, U.S., 3D Systems is an additive manufacturing solutions company. The company is principally engaged in providing 3D printing and digital manufacturing solutions. Its products and solutions include 3D printers for plastics and metals, materials, software, maintenance and training services, and on-demand solutions. In the 3D printers market, the company provides a wide range of products, including metal 3D printers, plastic 3D printers, metal casting 3D printers, dental 3D printers, and jewelry 3D printers. The solutions provided by the company are utilized in a wide range of industries and verticals, including aerospace, automotive,

healthcare, dental, semiconductor, and durable goods. Moreover, 3D Systems offers a broad range of 3D printing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Direct Metal Printing (DMP), MultiJet Printing (MJP), and ColorJet Printing (JCP). The company also offers 3D virtual reality simulators and simulator modules for medical applications.

The company markets its products and services through subsidiaries in North America and South America, Europe and the Middle East, and Asia-Pacific. As of December 2021, the company had a headcount of 1,721 employees globally.

Stratasys Ltd. (Israel)

Founded in 1998 and headquartered in Rehovot, Israel, Stratasys, Ltd. is a global leader in polymer-based 3D printing solutions. The company is a leading player in additive manufacturing, providing innovative 3D printing solutions. The company’s additive manufacturing ecosystem of solutions and expertise includes materials, software, expert services, and on-demand parts production. 3D printing systems provided by Stratasys utilize extrusion-based FDM, inkjet-based PolyJet, photopolymer-based P3, and open industry-based stereolithography technologies.

Stratasys has offices in 13 countries, including the Americas, Europe, and the Asia-Pacific.

Markforged Holding Corporation (U.S.)

Founded in 2015 and headquartered in Massachusetts, U.S., Markforged provides industrial additive manufacturing platforms. The company produces and sells industrial three-dimensional (3D) printers, software, and metal and composite materials.

Digital Forge is an industrial additive manufacturing platform that combines 3D printers and metal and composite materials with its cloud-based software. The company combines precise and reliable 3D printers and metal and proprietary composite materials. Its portfolio of 3D printers includes desktop printers, industrial printers, and metal printers. It provides an industrial 3D printing solution for fabricating composite, continuous fiber, and metal parts.

The company offers four fibers: carbon fiber, fiberglass, kevlar, and high-strength high-temp (HSHT) fiberglass. It provides solutions across the aerospace, military and defense, industrial automation, healthcare, and automotive industries. The company’s manufacturing and operations teams are based in Massachusetts and have remote teams and partners across the U.S., Canada, Europe, the U.K., Asia, and Australia.

Voxeljet AG (Germany)

Founded in 1999 and headquartered in Friedberg, Germany, voxeljet is a leading provider of high-speed, large-format 3D printers and on-demand parts services for industrial and commercial use. The company’s 3D printers employ powder binding and additive manufacturing technology to produce parts using various material sets, including

particulate materials and proprietary chemical binding agents. voxeljet provides 3D printers and on-demand parts services to industrial and commercial customers serving the automotive, aerospace, art and architecture, engineering, and consumer product markets. The company has a presence in 26 countries in the Americas, Asia, Africa, the Middle East, and Europe.

Desktop Metal, Inc. (U.S.)

Founded in 2015 and headquartered in Massachusetts, U.S., Desktop Metal provides additive manufacturing technologies focused on producing end-use parts. The company combines precise and reliable 3D printers and metal and composite proprietary materials. Industries served by Desktop Metal Inc. are automotive, consumer goods, heavy industry, manufacturers of industrial equipment, education, and machine design. In February 2021, Desktop Metal Inc. acquired EnvisionTEC Inc., a leading global provider of professional-grade 3D printing solutions, and in November 2021, the company acquired The ExOne Company, a leader in binder jetting technology

Popular Mentions: Carbon Inc. (U.S.), XYZprinting Inc. (Taiwan), Formlabs Inc. (U.S.), Fusion3 Design LLC (U.S.), DWS s.r.l (Italy), and EOS GmbH (Germany).